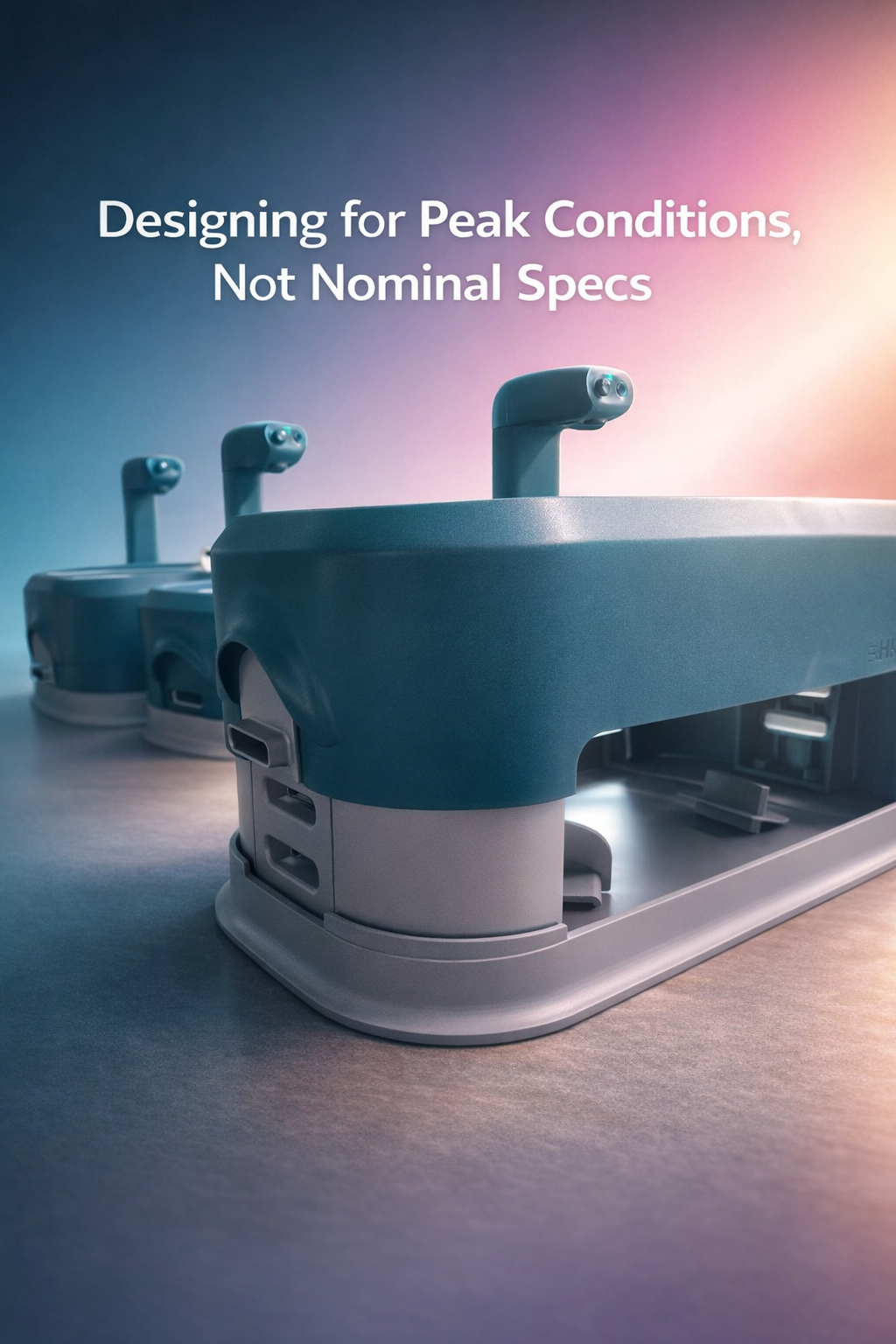

Designing for Peak Conditions, Not Nominal Specs

Most systems don’t fail when operating at their nominal specifications. They fail when real-world conditions push them into regions that were never fully modeled—transient overloads, off-axis forces, tolerance stack-ups, or repeated micro-stresses over time.

Nominal specs are typically defined under controlled laboratory conditions: room temperature (27 °C), centered loading, static forces, ideal mounting, and limited duty cycles. Real products operate far from this comfort zone.

While developing Everbowl, we learned that designing to nominal values alone creates systems that are accurate on paper but fragile in practice. Designing for peak conditions—the worst plausible combination of forces, misalignments, and usage—creates systems that remain predictable, stable, and trustworthy.

This blog explains why peak-condition design matters, how we applied it mechanically and structurally in Everbowl, and what engineers should internalize when moving from specification-driven design to real-world hardware.

Why Peak Forces Were Much Higher Than Nominal Loads

One of the most misleading assumptions in early design was treating the bowl load as purely static. In reality, the load applied to the Everbowl is rarely gentle or perfectly controlled. Dogs don’t just eat food from the bowl—they interact with it dynamically, nudging, pushing, and occasionally exploring the bowl.

From a mechanics perspective, this introduces dynamic amplification, where the instantaneous force experienced by the system is significantly higher than the static weight of the bowl and food.

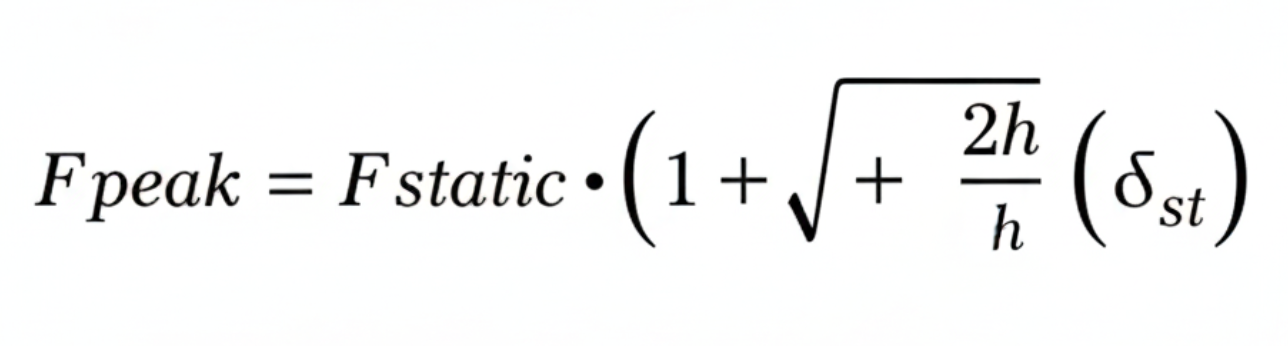

The peak force can be approximated using a Dynamic Amplification Factor (DAF):

Where:

- F subscript static is the nominal bowl + food weight

- h is the effective height from which the load is applied which is 150mm

- δ subscript st is the static deflection of the aluminum ring structure under nominal load

What this relationship makes clear is that peak force is not linearly related to weight. Even small dynamic inputs—on the order of a few millimeters of vertical motion from a dog’s snout—can result in:

F peak ≈ 2 to 3×F static

This was a critical realization for Everbowl. Designing only to the nominal food weight would have placed the system well into nonlinear behavior during normal use. Instead, the aluminum rings, load paths, and mounting strategy were designed assuming these amplified peak forces, ensuring that the load cell remained within its linear, predictable operating range even during real-world interaction.

In practice, this meant the structure wasn’t just strong enough—it was stable, which is exactly what a measurement system needs to be.

How We Determined F static from Simulation

In the context of Everbowl, F static represents the nominal load transferred through the bowl–ring–load cell stack under equilibrium conditions. This value is not theoretical—it needs to reflect how force actually flows through the physical structure.

Rather than calculating it analytically, F static was extracted from static structural simulation, using boundary conditions that mirrored real assembly and use.

At a high level, the process was:

- The bowl and food mass were modeled as a vertical gravitational load

- Load was applied at the actual contact region between the bowl and the top aluminum ring

- The bottom ring was constrained to represent fastening to the body via threaded inserts

- Material properties for aluminum (E ≈ 69 GPa) were used to capture realistic stiffness

Under these conditions, the simulation was allowed to settle into static equilibrium.

At convergence, F static was obtained in one of two equivalent ways:

1. Reaction force at constraints

The summed vertical reaction forces at the bottom ring fasteners directly represented the static load transmitted through the structure. This is often the most reliable measure because it reflects the full load path, not just local stresses.

2. Load transmitted through the load-cell interface

By probing the contact or bonded interface where the load cell sits between the two aluminum rings, the normal force passing through that interface could be extracted. This value maps most closely to what the sensor actually experiences in the product.

Both approaches consistently yielded the same order of magnitude, confirming that the system was behaving linearly under nominal conditions.

Why Simulation Matters for F static

The key advantage of simulation is that it captures load redistribution caused by geometry and constraints. In Everbowl, the bowl load is not applied perfectly centrally; even under static conditions, slight eccentricity creates uneven force sharing across the ring and fasteners.

This simulated F static then becomes the baseline against which dynamic amplification is evaluated—making the peak-load analysis grounded in the real mechanical behavior of the product.

What Engineers Should Internalize When Moving From Specification-Driven Design to Real-World Hardware

Moving from specification-driven design to real-world hardware requires a mental shift: accepting that specifications describe intention, not behavior. The aluminum rings, load cell interfaces, and threaded inserts taught us that repeatability matters more than peak accuracy, and that predictability under stress is a stronger measure of success than compliance under ideal conditions. Simulation became meaningful only when it reflected assembly reality, tolerances, and material interaction—not just boundary conditions. Designing for peak conditions wasn’t about adding margin everywhere, but about shaping how the system deforms, reacts, and recovers when assumptions inevitably fail. In the end, Everbowl wasn’t validated by meeting its specifications; it was validated by behaving consistently in the hands—and mouths—of real dogs.

Hoomanely Context

At Hoomanely, the focus is on building technology that survives real-world interaction—human, animal, and environmental.

Designing for peak conditions reflects a core philosophy. By accounting for worst-case loading, tolerance stack-ups, and long-term behavior, Everbowl’s design strengthens Hoomanely’s technology foundation—ensuring that what works in testing continues to work in daily life.