When Alignment Drift Became a System-Level Bug

In precision product engineering, failures rarely originate from a single catastrophic event. More often, they emerge quietly—through small, acceptable deviations that compound over time. During the development of Everbowl at Hoomanely, one such subtle issue transformed into a full system-level reliability challenge: alignment drift.

What initially appeared to be minor assembly variation began influencing load distribution, torque behavior, and structural response across the product. The result was not outright failure, but reduced predictability—arguably more dangerous in mechanical systems where user trust depends on consistency.

This case highlights a crucial engineering realization: systems designed purely around nominal values can perform flawlessly in CAD simulations yet behave unpredictably in real-world usage. Understanding alignment drift, and designing systems that tolerate it, became a defining learning in building Everbowl.

Context

Everbowl is designed as a stability-critical product where load transfer and user interaction directly influence mechanical performance. Because the bowl experiences dynamic loading during normal usage, structural integrity depends heavily on how forces travel through the assembly.

During early prototyping, performance results matched simulation expectations. However, long-term testing revealed small variations in load response between units. Over repeated use cycles, some assemblies demonstrated slight rotational play and localized stress concentration.

These inconsistencies traced back to alignment drift—a gradual positional deviation between structural components caused by manufacturing tolerances, assembly variability, and operational loading.

Challenge

The design challenge was not simply preventing drift, but understanding how microscopic positional changes created macroscopic system behavior changes.

Several symptoms began to appear:

- Load distribution across support structures became uneven.

- Eccentric loading introduced unexpected torque.

- Fasteners experienced variable preload retention.

- Stress concentrations formed in aluminum load-bearing members.

Individually, each symptom remained within acceptable engineering tolerance. Together, they introduced a system-level reliability concern.

Approach

We, the design team at Hoomanely shifted from evaluating individual component strength to analyzing the entire load path ecosystem. Instead of asking, “Is each component strong enough?” the question became:

“Does the system remain predictable when every component deviates slightly from its nominal state?”

This shift required three major methodological changes:

- Studying tolerance stack-ups as dynamic rather than static values.

- Simulating worst-case alignment conditions instead of ideal assemblies.

- Measuring real-world joint behavior over repeated load cycles.

Process

1. Identifying Alignment Drift Sources

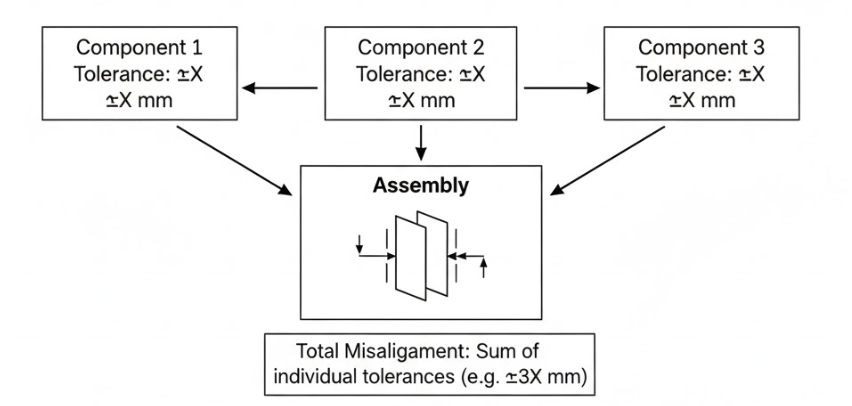

Alignment drift typically originates from three interacting factors:

Manufacturing Tolerances

Even precision CNC and sheet metal fabrication introduce dimensional variation. Industry machining tolerances for aluminum structural parts often range between ±0.02 mm and ±0.1 mm depending on manufacturing process and cost constraints.

When multiple components stack together, these small variations can compound.

Assembly Variability

Human assembly introduces angular and positional variation. Fastener tightening sequence, torque application differences, and part seating behavior can shift component alignment subtly.

Operational Load Cycling

Repeated loading causes micro-plastic deformation and fastener relaxation. Over time, these effects slightly shift load paths.

Tolerance Stack-Up Illustration

Diagram showing multiple components with individual tolerances combining into cumulative misalignment.

Caption: Small dimensional variations compound into system-level positional drift.

2. Load Path Analysis

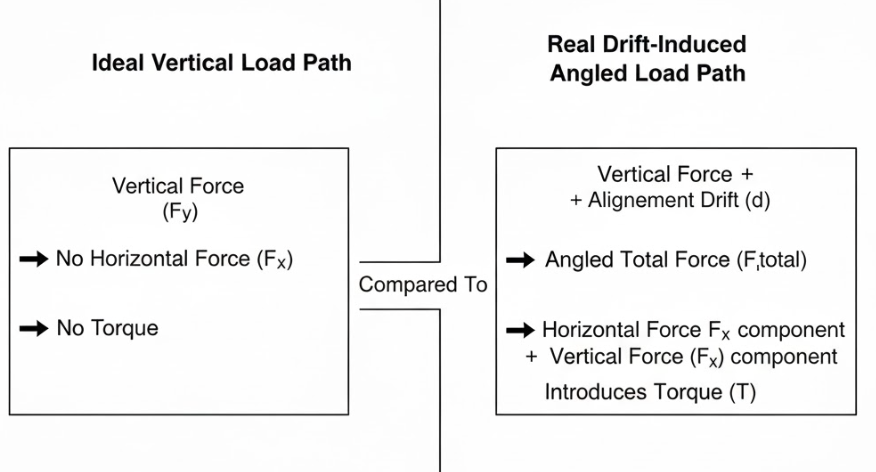

Traditional design often assumes direct vertical load transfer. Real-world testing showed that drift introduced multi-directional force components:

- Vertical compression

- Lateral shear forces

- Rotational torque loads

Load path complexity increased dramatically once alignment deviated.

Engineering Solution

To address these system-level behaviors, we, the design team, implemented structural and assembly-focused improvements that increased tolerance resilience rather than merely tightening tolerances.

Increased Stiffness of Load-Bearing Aluminum Components

Aluminum components were redesigned with increased section modulus and rib reinforcement. By improving structural stiffness, the system became less sensitive to minor misalignments.

Higher stiffness reduced deflection under peak load conditions, preserving intended load paths and minimizing stress amplification.

Industry benchmarking suggests that increasing structural stiffness by 15–30% can reduce alignment-induced deflection by nearly half in load-sensitive assemblies.

Introduced Threaded Inserts to Maintain Consistent Joint Preload

Fastener preload stability plays a critical role in preventing alignment drift over time. Direct fastening into aluminum threads can lead to wear and preload relaxation.

We introduced threaded inserts to:

- Improve thread durability

- Maintain long-term preload consistency

- Reduce fastener loosening from cyclic loading

Threaded inserts are widely used in aerospace and automotive industries specifically for maintaining preload stability in soft metal assemblies.

Improved Assembly Alignment Features

Assembly alignment features were redesigned to reduce positional variability during installation. These included:

- Precision dowel-based alignment guides

- Self-locating geometry interfaces

- Assembly sequencing improvements

These features reduced reliance on installer judgment and improved repeatability across production units.

We had particularly used this for our load bearing ring assembly.

Results

After implementing the redesign, several performance improvements were observed during validation testing:

- Reduced load response variability between units

- Improved fastener preload retention over repeated load cycles

- More consistent user stability perception

Fatigue testing showed measurable improvements in structural durability and long-term alignment stability.

Most importantly, the system transitioned from being tolerance-sensitive to tolerance-resilient.

Learnings

1. Nominal Design is Only the Starting Point

CAD models represent perfect assemblies. Real products operate within tolerance ranges. Engineering must account for variability as a design input, not an afterthought.

2. Alignment is a System Property, Not a Component Property

Individual parts can meet dimensional requirements while the assembled system still drifts. System-level load path thinking is essential.

3. Stiffness Improves Predictability

Strength prevents failure. Stiffness prevents performance drift. In stability-critical products, stiffness often has higher functional importance.

4. Assembly Design is Structural Design

Repeatability in assembly can be as important as material selection or structural geometry.

Hoomanely Context

At Hoomanely, product development focuses on creating hardware systems that are not only functional but deeply reliable in everyday use. The lessons from alignment drift directly support the company’s mission of building products that feel stable, intuitive, and trustworthy.

By prioritizing real-world behavior over theoretical performance, this engineering work strengthens Hoomanely’s long-term product philosophy—designing hardware that performs consistently across diverse usage conditions and lifecycle stages.

Key Takeaways

- Small positional deviations can escalate into system-level reliability risks.

- Designing for worst-case tolerance conditions improves product predictability.

- Structural stiffness plays a critical role in maintaining alignment stability.

- Joint preload retention is essential for long-term mechanical integrity.

- Assembly alignment features significantly improve manufacturing consistency.

- Load path optimization reduces torque-induced stress amplification.

Conclusion

Alignment drift taught an important engineering truth: precision is not achieved by eliminating variation, but by designing systems that remain stable despite it. Mechanical products live in a world of tolerances, wear, and human interaction. Designs that assume perfection often fail quietly under real-world complexity.

Everbowl’s development journey reinforced the importance of resilience-driven engineering—where predictability, durability, and user confidence become core design metrics alongside strength and aesthetics. In doing so, alignment drift transformed from a hidden defect into a guiding design philosophy, shaping how robust products are conceived, validated, and delivered.