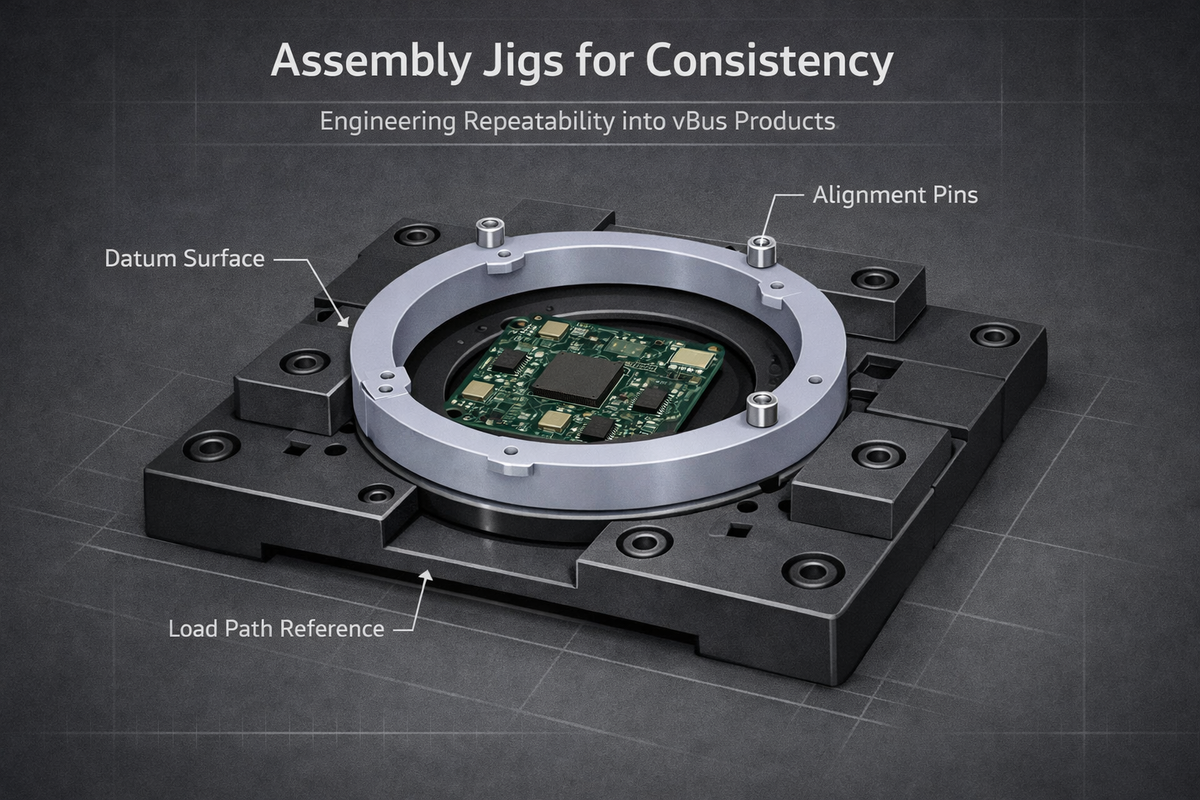

Assembly Jigs for Consistency: Engineering Repeatability into vBus Products

Introduction: Precision Is Designed, Not Assumed

In hardware systems that blend mechanical structure, electronics, and sensing, consistency is not a byproduct of careful assembly—it is an engineered outcome. As Hoomanely’s vBus-based products matured into tightly integrated systems, the tolerance for variation narrowed dramatically. Mechanical alignment, sensor positioning, connector engagement, and enclosure fit all became first-order design variables that directly influenced performance and reliability.

To enforce this consistency at scale, assembly and test jigs became foundational infrastructure. These tools define physical reference frames for assembly and verification, ensuring that every unit—regardless of production volume or operator—converges to the same intended geometry and behaviour.

This article focuses on two critical jig systems: metal ring assembly jigs used in load-bearing, sensor-sensitive products, and automated test jigs that validate electrical and functional integrity across the broader vBus product family.

Why Mechanical Repeatability Matters

vBus products are modular by design, but their performance depends on precise mechanical relationships between components. Small deviations during assembly can introduce subtle yet impactful effects:

- Uneven mechanical preload alters sensor response

- Misalignment creates localised stress in PCBs and connectors

- Inconsistent enclosure fit affects thermal paths and vibration behaviour

- Variable electrical contact quality impacts signal integrity

These effects are cumulative and often invisible during casual inspection. Assembly jigs eliminate this variability by enforcing repeatable constraints at the physical level.

Metal Ring Assembly Jigs: Defining the Load Path

In products where mechanical structures interface directly with sensing systems—such as metal ring assemblies—the geometry of assembly is inseparable from functional performance.

Metal ring assembly jigs serve as the authoritative mechanical reference during build. They establish:

- Exact concentric alignment of ring components

- Controlled vertical spacing between structural elements

- Uniform preload distribution across mounting points

By constraining all six degrees of freedom during fastening, the jig ensures that the load path through the ring remains consistent across units. This prevents asymmetric stress, eliminates tilt, and maintains sensor-neutral mechanical conditions.

The jig’s role is not to hold parts in place temporarily, but to encode the final operating geometry during assembly.

Eliminating Assembly-Induced Stress

Mechanical stress introduced during assembly can persist throughout a product’s life, subtly degrading performance over time. Metal ring jigs mitigate this by:

- Providing flat datum surfaces that prevent torsional loading

- Controlling fastener compression depth

- Ensuring parallelism between mating surfaces

As a result, once the product is removed from the jig, internal stresses are minimised. The structure behaves as intended under operational loads rather than compensating for assembly artefacts.

Consistency Across Operators and Batches

One of the defining advantages of dedicated assembly jigs is operator independence. The jig enforces alignment passively, making correct assembly the default outcome rather than a skill-dependent task.

This consistency is critical when:

- Scaling production volumes

- Introducing new assembly personnel

- Maintaining uniformity across manufacturing batches

The jig becomes the single source of mechanical truth, ensuring that every unit begins life in the same physical state.

Automated Test Jigs as Functional Gatekeepers

While assembly jigs define geometry, test jigs validate behaviour.

Automated test jigs are designed to interface with fully assembled products and perform repeatable electrical and functional verification without manual probing or interpretation. They provide:

- Repeatable electrical connections via spring-loaded contacts or edge connectors

- Controlled power sequencing and load conditions

- Automated measurement of key signals and responses

These jigs transform testing from a subjective activity into a deterministic, data-driven process.

Test Jigs as Extensions of the vBus Architecture

Test jigs are designed with the same modular philosophy as vBus products themselves. Each jig aligns with standardised interfaces and test points, allowing:

- Rapid adaptation across product variants

- Reuse of core test infrastructure

- Parallel testing of multiple units

By embedding test access into the product architecture early, the test jig becomes a natural extension of the system rather than an external workaround.

Automated Validation Without Human Interpretation

Automated test jigs eliminate ambiguity by:

- Applying known input conditions

- Measuring expected outputs

- Comparing results against predefined thresholds

This approach ensures that:

- Every unit is evaluated under identical conditions

- Results are independent of operator judgment

- Edge cases are detected consistently

The outcome is higher confidence in product quality with reduced inspection overhead.

Assembly and Test as a Unified System

At Hoomanely, assembly and testing are not treated as isolated steps. The design of metal ring jigs and test jigs is coordinated to ensure that:

- Mechanical references established during assembly align with test interfaces

- Products transition from assembly to validation without reorientation or adjustment

- Test results reflect real operational geometry

This continuity reduces handling, minimises the risk of damage, and preserves alignment integrity throughout the build process.

Throughput With Predictability

Jigs improve speed not by rushing assembly, but by removing uncertainty. When alignment, positioning, and verification are built into the process:

- Assembly steps become repeatable

- Testing becomes parallelizable

- Rework becomes rare

This predictability supports efficient production planning without sacrificing quality.

Designing Jigs as Engineering Assets

Both assembly and test jigs are treated as long-term engineering assets. They are:

- Designed in parallel with product hardware

- Version-controlled alongside mechanical and electrical designs

- Updated deliberately as products evolve

This ensures that improvements to the product architecture are reflected in the tooling that supports it.

Quality as a System Property

Consistency is not enforced at the inspection stage—it is created at the assembly stage and confirmed at the test stage.

Metal ring assembly jigs ensure that mechanical conditions are correct by construction. Automated test jigs verify that electrical and functional behaviour aligns with expectations. Together, they create a closed-loop system where quality is engineered into the process rather than checked in afterwards.

Conclusion: Infrastructure That Makes Quality Routine

Assembly and test jigs rarely appear in product specifications, yet they play a decisive role in whether sophisticated designs perform reliably at scale.

By investing in:

- Precision metal ring assembly jigs for mechanical repeatability

- Automated test jigs for objective validation

Hoomanely ensures that every vBus-based product leaves assembly in a known, verified state—mechanically stable, electrically sound, and functionally consistent.

This is a manufacturing discipline applied with engineering intent. When alignment is defined, behaviour is measured, and variation is constrained, quality ceases to be an aspiration and becomes a routine outcome.