Building a Board That Can Boot With Missing Sensors

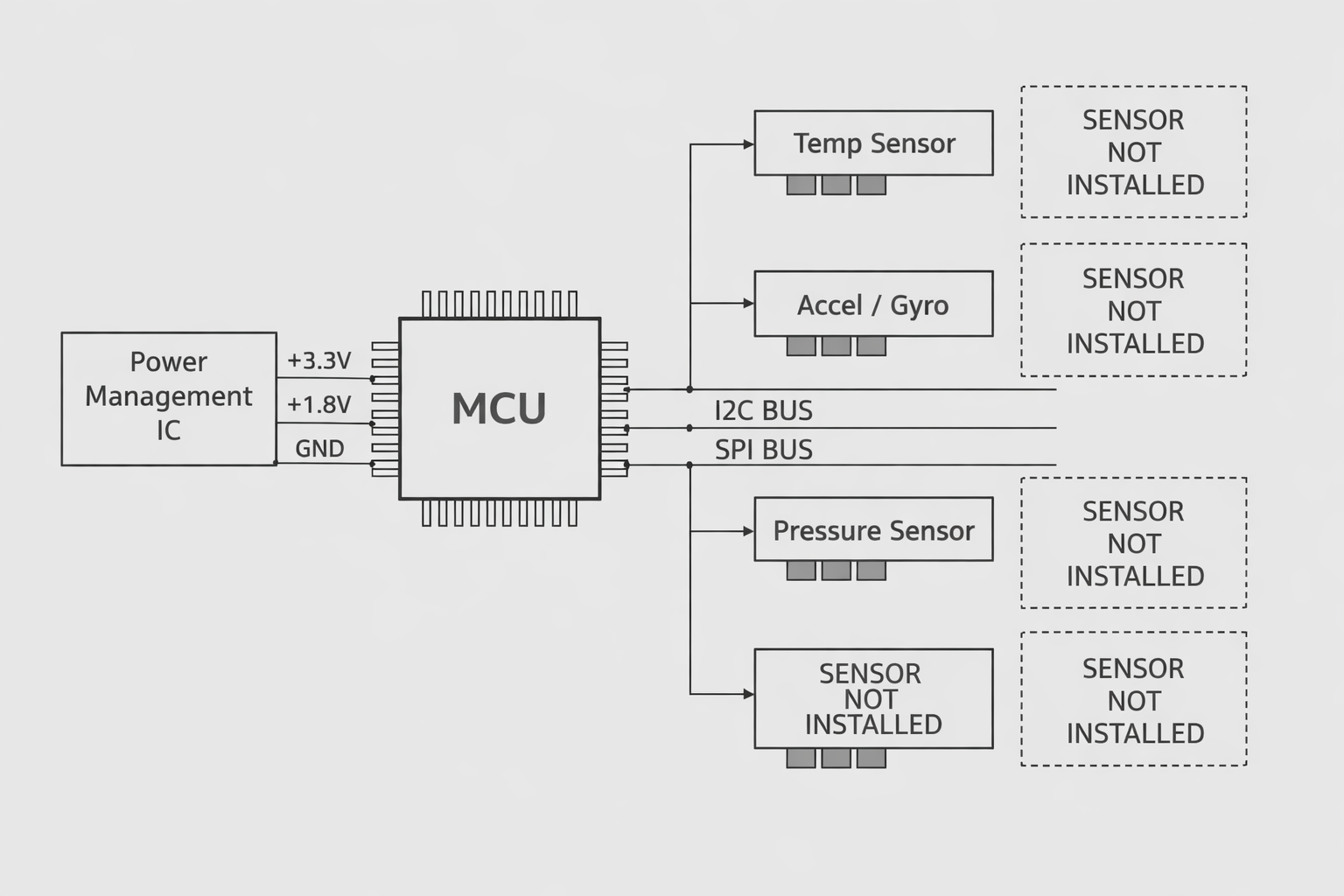

Most boards are designed under a quiet assumption: everything that should be present will be present.

All sensors are populated. All cables are connected. All rails come up cleanly. Firmware discovers what it expects, and the system progresses forward.

That assumption holds in the lab. It collapses the moment a product meets manufacturing reality, field servicing, or iterative development.

At Hoomanely, we’ve learned that a system that requires perfect population to boot is not robust—it’s brittle. Sensors will be missing. Modules will be unplugged. Assemblies will be partial. Firmware will lag behind hardware revisions. And yet, the board must still power up, still be observable, and still make sense.

Designing a board that can boot with missing sensors is not about ignoring faults. It’s about separating absence from failure—and encoding that distinction in hardware, not hope.

This article explores what it takes to build systems that remain alive, intelligible, and recoverable even when pieces are missing.

Absence Is Not a Fault—Unless You Treat It Like One

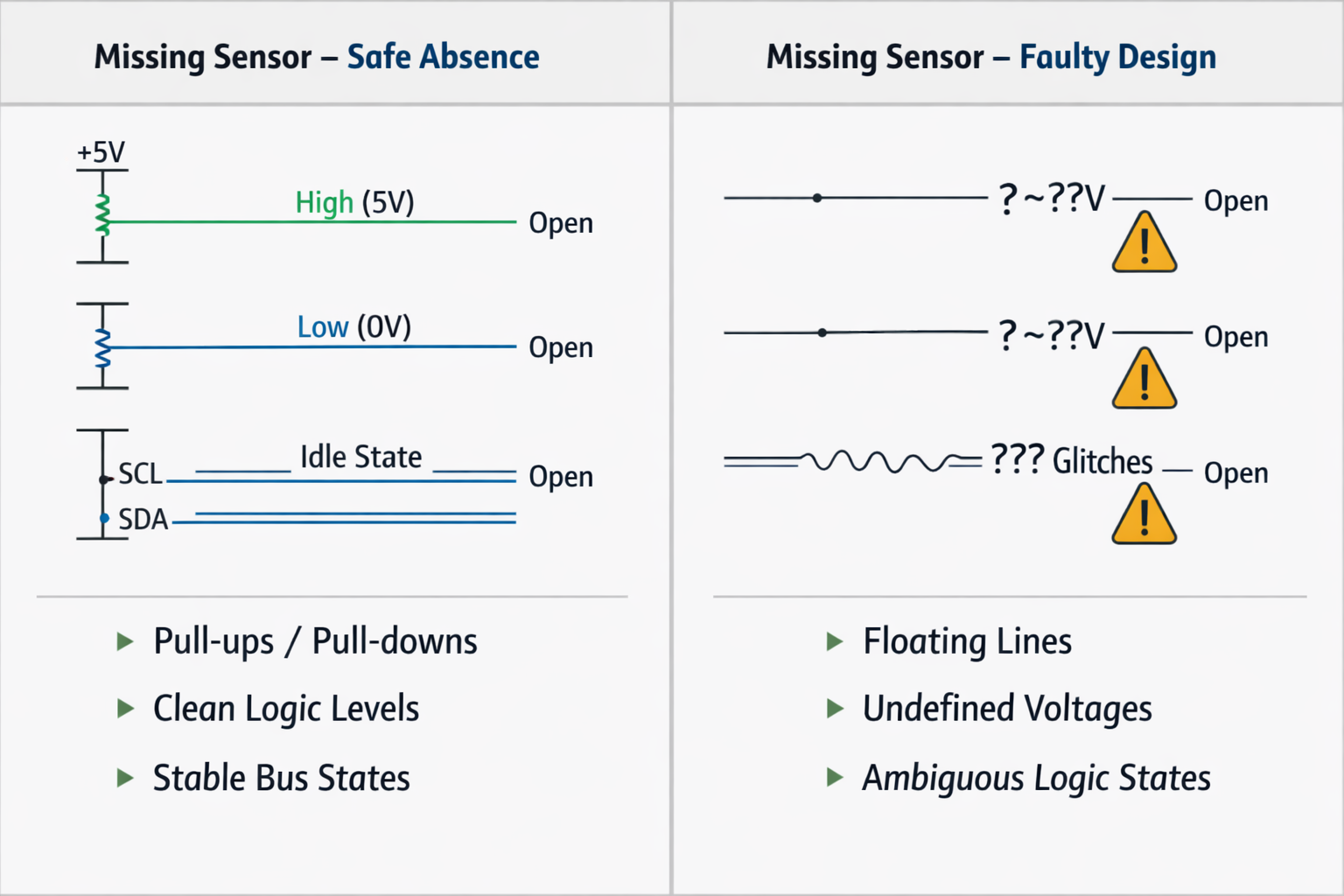

From an electrical perspective, a missing sensor is not inherently dangerous. What makes it dangerous is how the rest of the system reacts to its absence.

Common failure patterns include:

- Floating inputs interpreted as valid signals

- Shared buses stalled by non-responding devices

- Power rails overloaded by assumptions about downstream load

- Firmware stuck waiting for hardware that will never respond

In each case, the system confuses absence with malfunction.

A resilient board makes absence explicit. It ensures that:

- Inputs settle to known, safe states

- Buses continue to function when devices are missing

- Power consumption remains bounded

- Boot flow is not blocked by optional components

This is not about making everything optional. It’s about making optionality intentional.

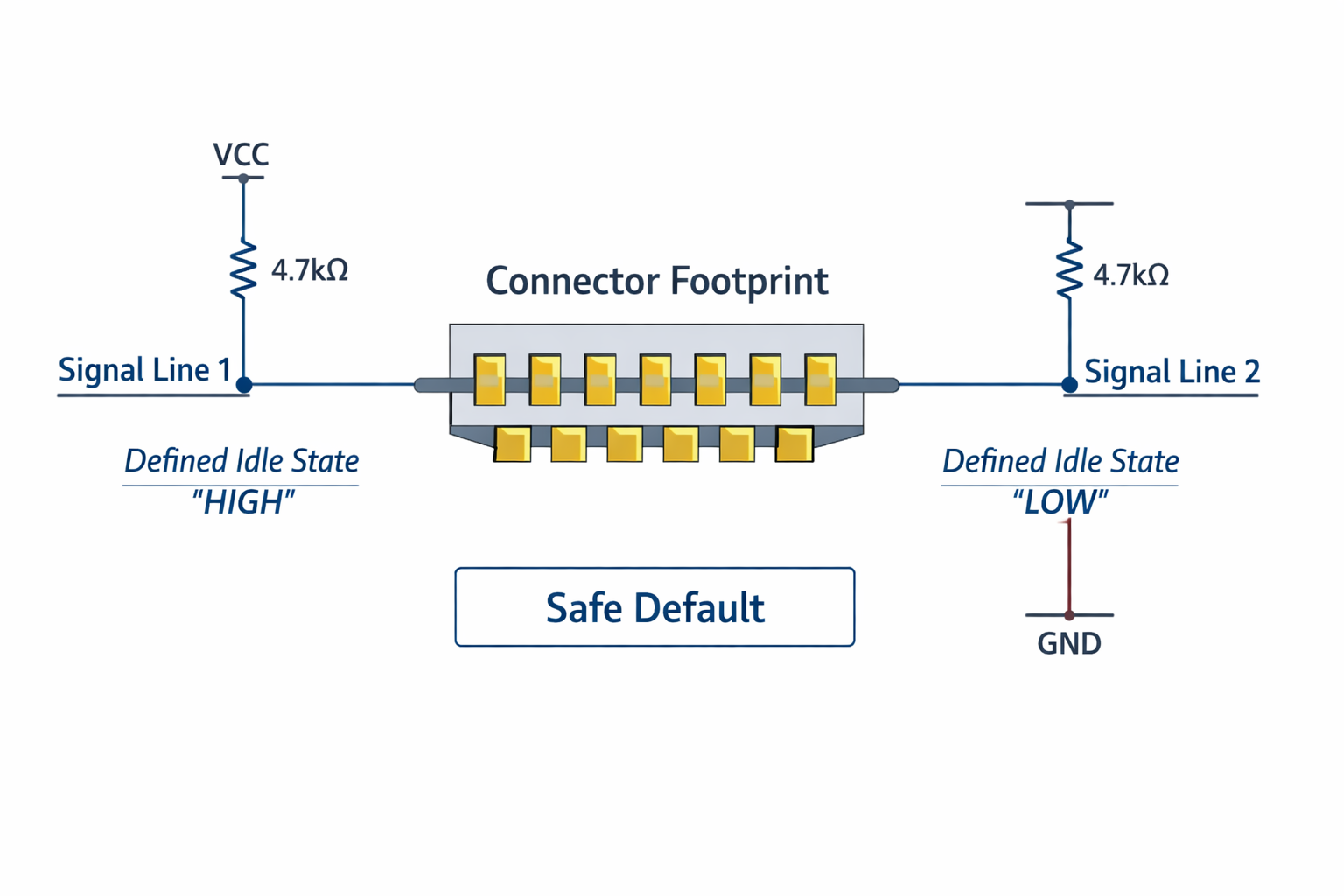

Electrical Defaults Are Architectural Decisions

The first line of defense against missing sensors is not firmware—it’s electrical defaults.

Every signal that leaves a connector or footprint must answer a simple question when nothing is attached: what happens now?

Good defaults are:

- Predictable

- Benign

- Distinguishable from valid activity

Poor defaults are:

- Floating

- Ambiguous

- Dependent on timing coincidences

A board that boots reliably with missing sensors ensures that:

- Control lines assume safe states

- Interfaces remain electrically quiet

- Absence does not masquerade as valid data

These choices are architectural. They define how the system behaves in incomplete configurations long before firmware logic executes.

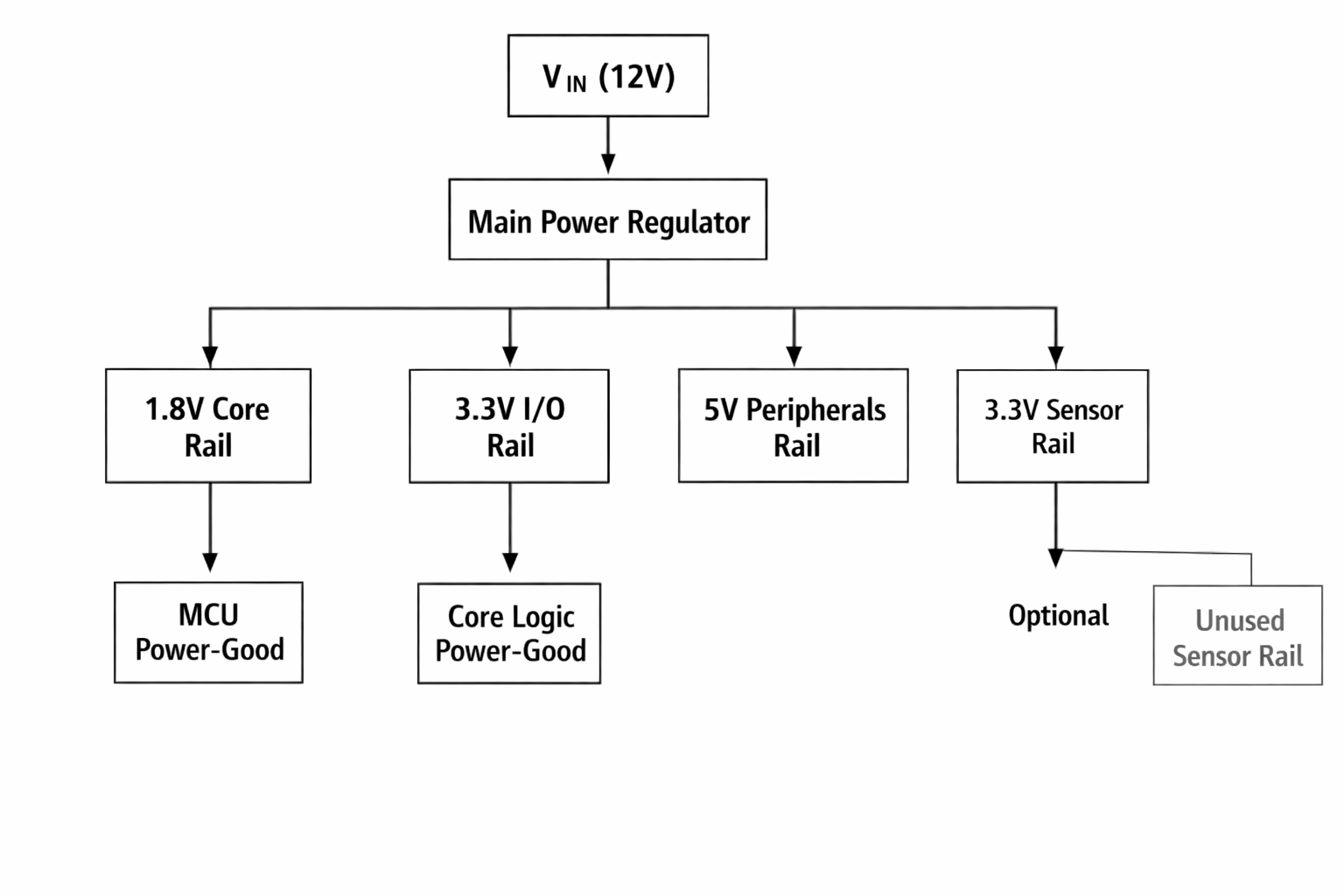

Power Should Not Be Held Hostage by Optional Loads

One of the most common boot failures in partially populated systems is power-related.

Designs often assume:

- Certain loads will always be present

- Downstream rails will always draw expected current

- Power-good behavior reflects a fully populated system

When sensors are missing, these assumptions break. Rails may rise too quickly or too slowly. Supervisory logic may misinterpret conditions. Entire domains may fail to enable.

A board designed to tolerate missing sensors treats power as independent of feature completeness.

This means:

- Power rails enable based on system intent, not downstream presence

- Power-good logic tolerates wide load variation

- No single optional module can block system-wide power-up

The result is a system that powers predictably whether one sensor is present or ten.

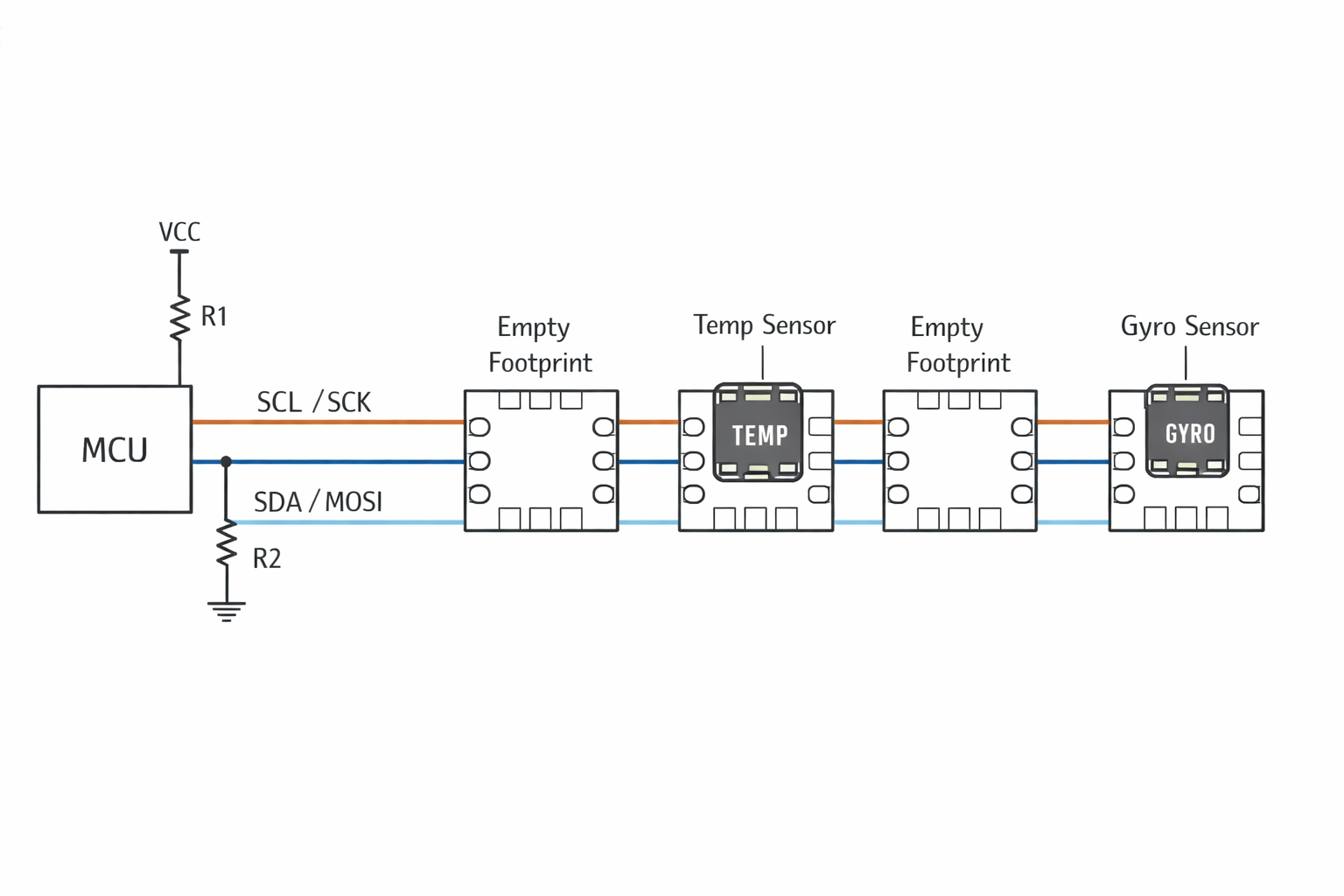

Buses Must Degrade Gracefully

Shared buses are particularly vulnerable to missing devices.

On many boards, a single absent or misbehaving peripheral can:

- Stall initialization

- Hold lines in undefined states

- Prevent other devices from communicating

A board that boots with missing sensors must ensure that:

- Buses remain operable with zero, one, or many devices attached

- No device is required for bus viability

- Absence is electrically distinct from contention

This often means designing buses so that:

- Idle states are well-defined

- Pulling behavior does not depend on population

- Optional endpoints cannot dominate shared resources

When buses degrade gracefully, firmware gains flexibility. It can discover what exists rather than assume what should.

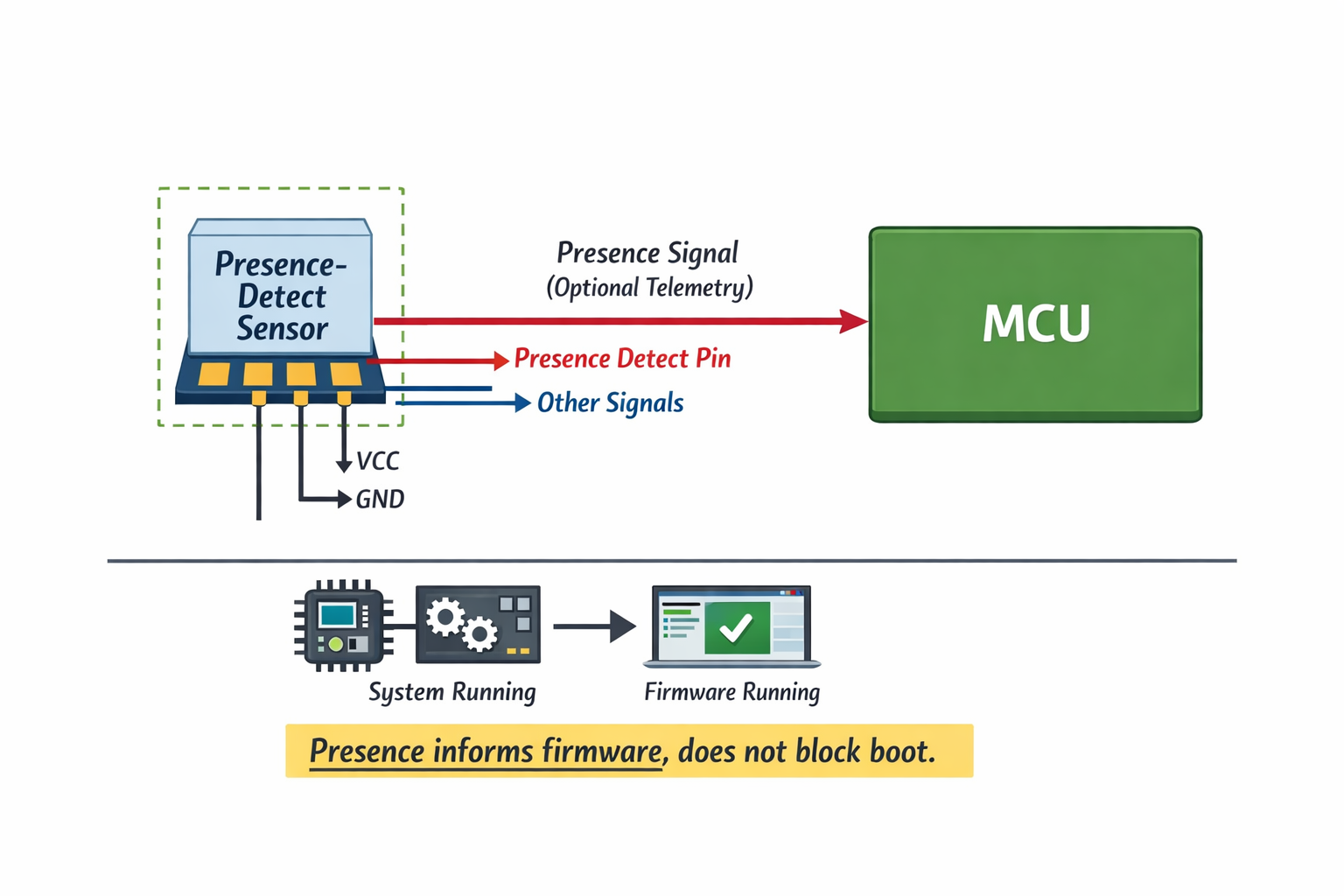

Presence Detection Is About Clarity, Not Control

Detecting whether a sensor is present is useful—but only if presence information is trustworthy.

Presence detection should:

- Be hardware-visible

- Be unambiguous

- Be independent of firmware probing sequences

Crucially, presence detection should not be required for safe operation. A system should not need to know that a sensor is missing in order to remain stable.

Instead, presence signals serve two purposes:

- Improving observability during bring-up and diagnostics

- Allowing firmware to adapt behavior without guesswork

Presence should inform decisions, not gate basic system life.

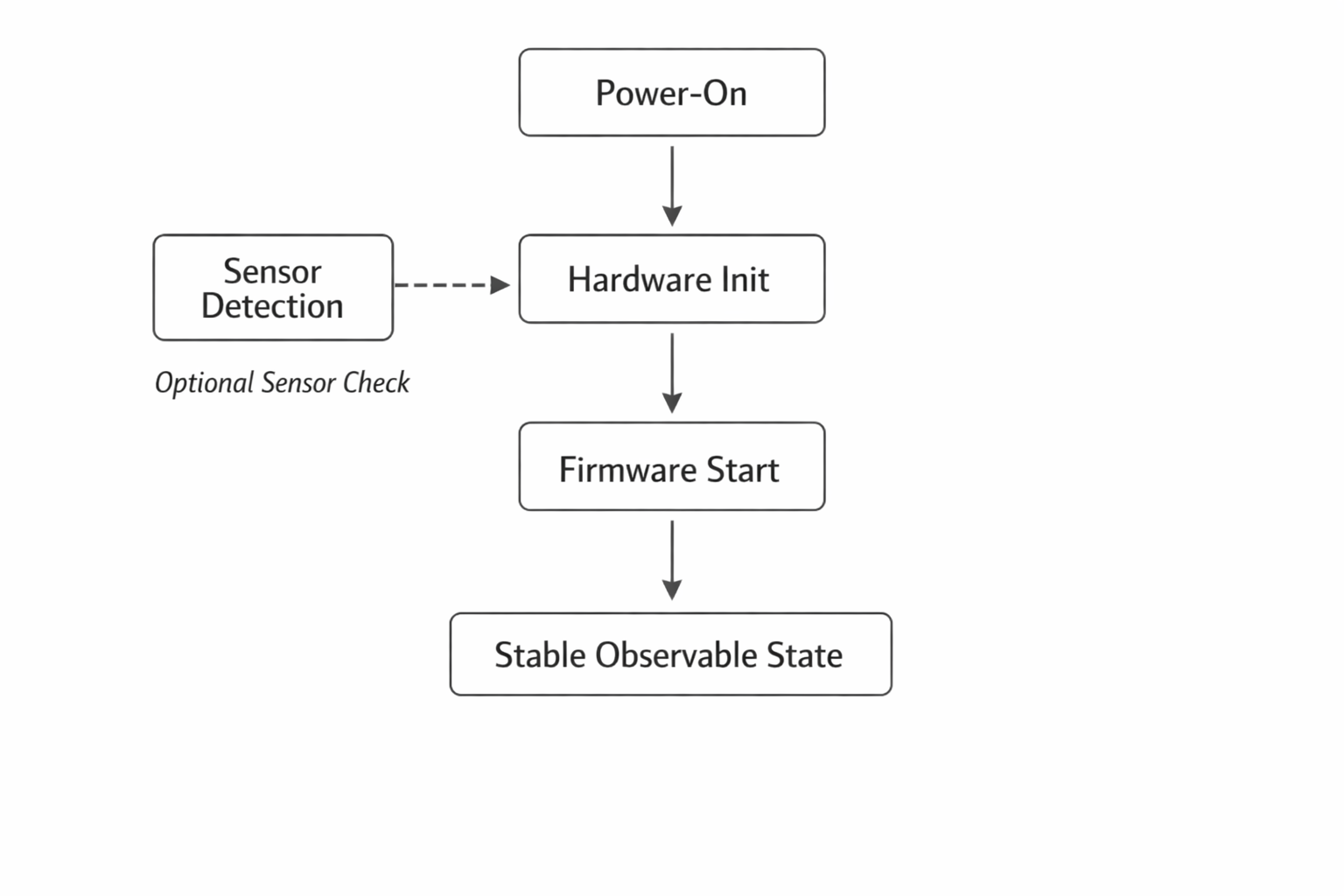

Boot Must Be Finite

One of the most subtle failure modes in partially populated systems is infinite boot.

This happens when firmware waits—explicitly or implicitly—for something that never arrives:

- A response that never comes

- A condition that never resolves

- A peripheral that is not there

From the outside, the system appears dead. In reality, it is alive but trapped.

A board that boots with missing sensors ensures that:

- Hardware does not create conditions that require firmware to wait indefinitely

- Absence results in a known, finite state

- Boot progresses to a stable, observable point regardless of population

This doesn’t eliminate firmware responsibility—but it ensures firmware always has a chance to run, diagnose, and recover.

Manufacturing Reality Demands Partial Life

In manufacturing, boards rarely arrive fully assembled on the first pass.

Sensors may be:

- Populated in later steps

- Tested in isolation

- Omitted intentionally for certain SKUs

If a board cannot power up meaningfully in these states, manufacturing becomes fragile. Engineers resort to:

- Temporary jumpers

- Special firmware builds

- Tribal knowledge that doesn’t scale

By contrast, boards that tolerate missing sensors:

- Power up on the bench without special handling

- Expose clear signals about what is and isn’t present

- Allow staged validation of subsystems

This reduces bring-up time, rework cycles, and dependency on “the one engineer who knows the trick.”

Field Service Depends on Partial Functionality

In the field, missing sensors are not hypothetical. They happen because:

- A connector comes loose

- A module fails

- A cable is damaged

- A replacement is delayed

A system that treats missing sensors as fatal creates cascading failures:

- Users can’t diagnose the issue

- Support can’t access the system

- Recovery requires physical disassembly

A system that boots despite missing sensors behaves differently:

- It remains reachable

- It reports absence clearly

- It allows degraded but meaningful operation

This is the difference between a serviceable product and a disposable one.

Optional Does Not Mean Ignored

Designing for missing sensors does not mean ignoring them.

It means:

- The system does not collapse without them

- Their absence is visible, not catastrophic

- Their presence enhances capability, not viability

This distinction allows teams to:

- Iterate hardware and firmware independently

- Ship variants without redesigning fundamentals

- Add or remove features without destabilizing the platform

Optionality becomes a feature, not a liability.

Designing for Absence Improves Presence

One of the counterintuitive outcomes of this approach is that systems designed to tolerate missing sensors often behave better when everything is present.

Why?

- Electrical states are cleaner

- Power behavior is more predictable

- Buses are more robust

- Firmware logic is simpler

By forcing the design to be explicit about absence, it becomes more disciplined about presence.

A Board That Boots Is a Board That Teaches

Ultimately, a board that can boot with missing sensors is a board that can teach.

It teaches:

- Engineers what is connected

- Technicians what is wrong

- Firmware what is available

- Users that the system is still alive

Silence teaches nothing. Partial life teaches everything.

At Hoomanely, we don’t design boards that assume perfection. We design boards that survive incompleteness—because that is what real products face from day one.

A system that can boot when pieces are missing is not just more robust.

It is more honest about the world it lives in.