Building AI-Powered Air Quality Intelligence with Neural Gas Sensing

Introduction

Indoor air quality monitoring has evolved from simple threshold detection to intelligent pattern recognition. While traditional sensors measure concentration levels, the latest AI-powered gas sensing technology can distinguish between different gas compositions—like differentiating cooking smoke from chemical vapors or detecting bacterial growth through volatile sulfur compounds.

This technical deep dive explores implementing an AI-driven indoor air quality monitoring system using neural gas sensing, multi-sensor fusion, and edge computing. We'll examine how modern gas sensors with integrated machine learning capabilities can transform environmental monitoring from reactive detection to predictive intelligence, creating systems that understand not just what is in the air, but why it matters.

Traditional air quality sensors provide limited context about gas sources, require frequent calibration, and cannot adapt to specific environmental conditions without extensive manual tuning.

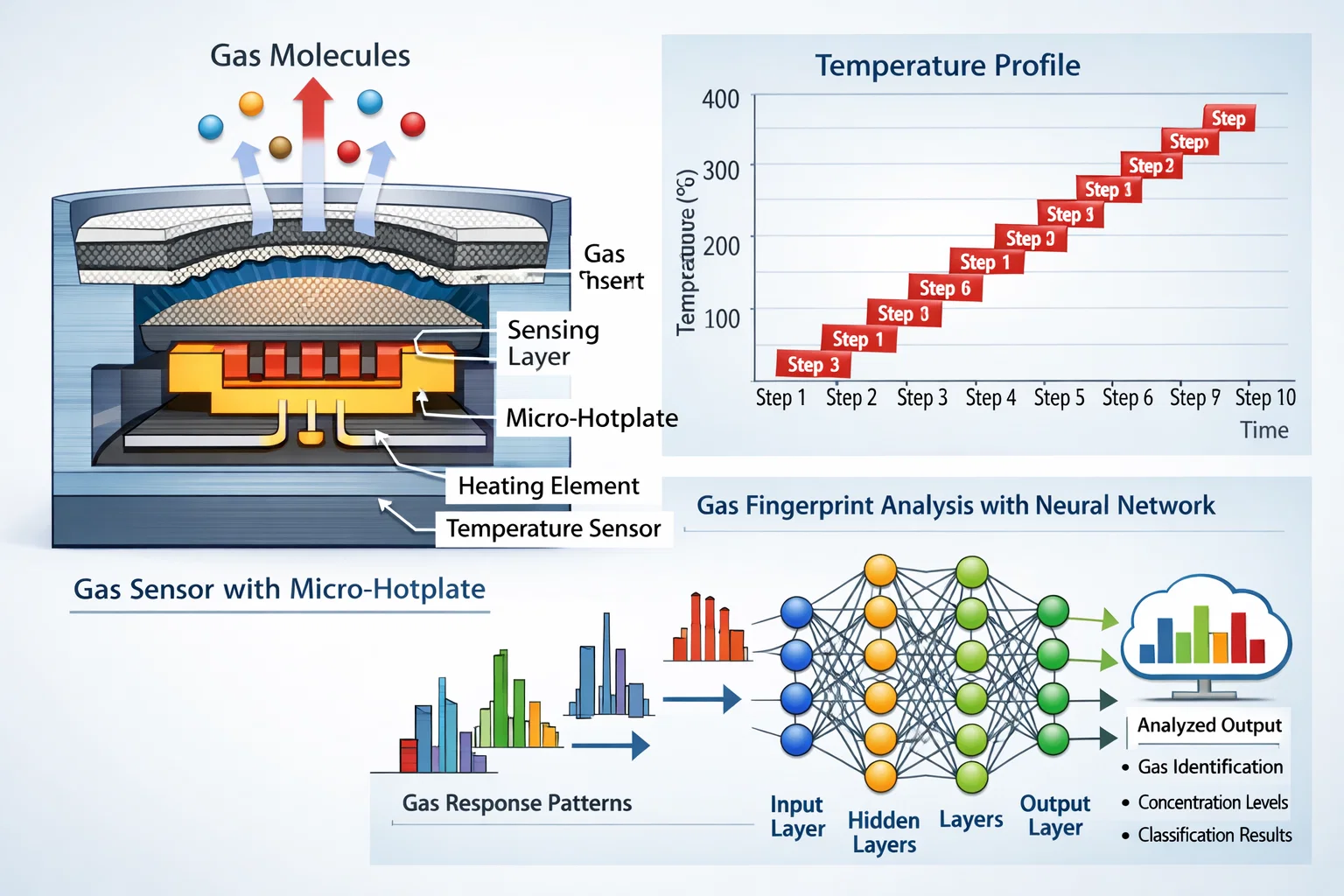

The Neural Gas Sensing Revolution

Beyond PPB Detection: Gas Fingerprinting

Modern environmental sensors equipped with AI capabilities represent a paradigm shift in gas detection. Unlike conventional metal-oxide sensors that simply measure resistance changes, AI-enhanced gas sensors create unique "fingerprints" for different gas compositions.

How Neural Gas Sensing Works:

The technology uses a micro-hotplate that cycles through precisely controlled temperature profiles—up to 10 distinct temperature steps with 140-millisecond timing precision. Each temperature step creates different surface chemistry conditions on the sensing element, generating unique electrical signatures for various gas mixtures.

Temperature Profile Example:

Step 1: 200°C (280ms) → Measure volatile organics

Step 2: 300°C (420ms) → Detect sulfur compounds

Step 3: 350°C (560ms) → Analyze combustion gases

...continuing through 10 optimized steps

AI Training Process:

- Data Collection: Record gas measurements across different environmental conditions

- Labeling: Associate measurements with known gas sources (cooking, cleaning, outdoor pollutants)

- Neural Network Training: Create classification algorithms using collected fingerprints

- Edge Deployment: Export trained models as configuration files for embedded systems

The result is a sensor that can distinguish between sources: cooking vapors versus chemical cleaning products, normal respiration CO2 versus combustion gases, or early fire detection versus cigarette smoke.

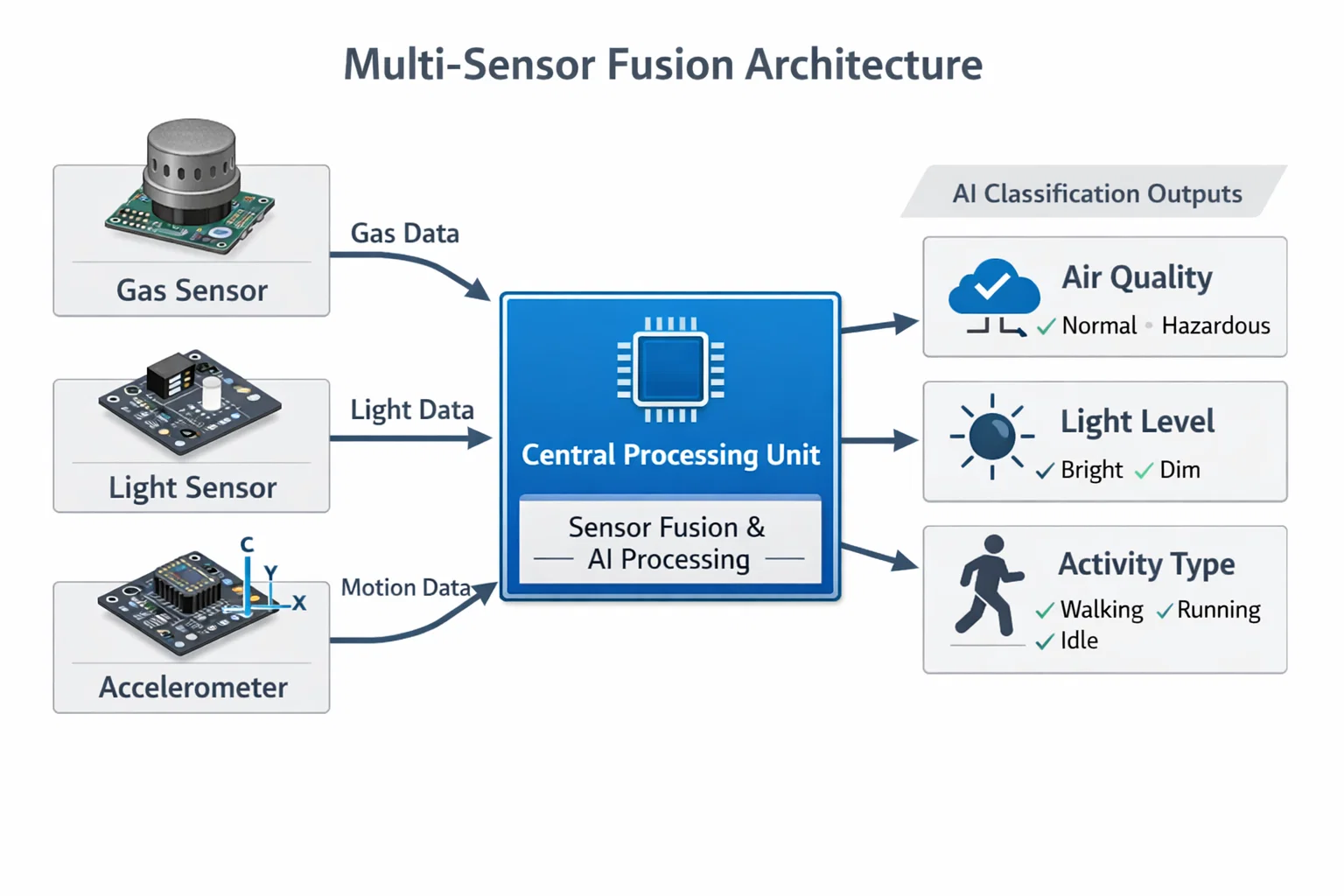

Multi-Sensor Fusion Architecture

Creating Environmental Intelligence

Single-sensor approaches miss critical contextual information. A comprehensive air quality monitoring system requires sensor fusion to understand occupancy patterns, environmental conditions, and behavioral contexts.

Core Sensor Integration:

Gas Sensing Module:

- PPB-level sensitivity for VOCs, VSCs, CO, and hydrogen

- Environmental compensation for temperature/humidity drift

- Real-time baseline correction every 60 seconds

Ambient Light Detection:

- 0.01 to 83,000 lux dynamic range with automatic scaling

- Human eye spectral response matching (550nm peak sensitivity)

- Interrupt-driven occupancy pattern detection

Motion and Vibration Analysis:

- Three-axis accelerometer with ±2g/±4g/±8g ranges

- Wake-up and free-fall detection algorithms

- FIFO buffering for pattern analysis without host intervention

Fusion Algorithm Design:

The system employs multiple fusion strategies:

- Early Fusion: Concatenate all sensor data streams for comprehensive pattern recognition

- Feature-Level Fusion: Extract temporal and spatial patterns from each sensor independently

- Decision-Level Fusion: Combine individual sensor classifications using ensemble methods

Recent research demonstrates that multi-sensor fusion approaches achieve over 90% accuracy in occupancy detection, compared to 70-80% for single-sensor methods.

Code Snippet - Sensor Fusion Configuration:

typedef struct {

float gas_resistance;

uint32_t light_lux;

int16_t accel_xyz[3];

float temperature;

float humidity;

} sensor_data_t;

// Fusion algorithm processing

fusion_result_t process_sensor_fusion(sensor_data_t* data) {

// Environmental compensation

float compensated_gas = apply_temp_humidity_correction(data);

// Pattern recognition

occupancy_state_t occupancy = analyze_movement_light_patterns(data);

air_quality_class_t aq_class = classify_gas_fingerprint(compensated_gas);

return combine_classifications(occupancy, aq_class);

}

Edge AI Implementation Strategy

Deploying Neural Networks on Microcontrollers

Running AI algorithms directly on embedded hardware eliminates cloud dependencies and enables real-time decision making. Modern ARM Cortex-M0+ microcontrollers can execute neural network inference while maintaining ultra-low power consumption.

Hardware Platform Selection:

The implementation uses a 48MHz Cortex-M0+ microcontroller with:

- 256KB Flash memory for model storage

- 36KB RAM for inference processing

- Dual I2C interfaces for multi-sensor communication

- FDCAN controller for building automation integration

Neural Network Optimization:

Edge deployment requires aggressive model optimization:

- Quantization: Convert 32-bit floating-point weights to 8-bit integers

- Pruning: Remove redundant neural connections (typically 70-80% reduction)

- Knowledge Distillation: Train smaller student networks from larger teacher models

Performance Metrics:

- Inference time: ~2.6ms for gas classification

- Power consumption: 3.9mA during active inference

- Memory footprint: <400KB including BSEC library

Development Workflow:

AI Studio Training → Model Export → Edge Compiler → MCU Deployment

↓ ↓ ↓ ↓

Gas fingerprint .config file Optimized C Real-time

collection generation code gen classification

The edge AI framework automatically generates optimized C code that integrates seamlessly with existing firmware, enabling rapid prototyping and deployment.

Building Automation Integration

HVAC Control Through Intelligent Air Quality

Modern building automation systems require standardized communication protocols for interoperability. The implementation leverages FDCAN (Flexible Data-Rate CAN) for high-speed, reliable communication with HVAC infrastructure.

Protocol Integration:

FDCAN provides compatibility with industrial automation standards:

- BACnet: Primary building automation protocol

- Modbus: Industrial sensor networks

- Custom protocols: Real-time air quality data streams

Predictive HVAC Control:

The system enables several intelligent building features:

Occupancy-Based Ventilation:

typedef struct {

uint8_t room_occupancy; // Detected person count

float co2_equivalent; // Air quality metric

uint8_t gas_class; // Classified gas source

uint32_t timestamp; // Event timing

} hvac_command_t;

void send_hvac_update(hvac_command_t* cmd) {

// Encode FDCAN message

fdcan_message_t msg = {

.id = HVAC_AIR_QUALITY_ID,

.data = serialize_hvac_command(cmd),

.length = sizeof(hvac_command_t)

};

fdcan_transmit(&hfdcan1, &msg);

}

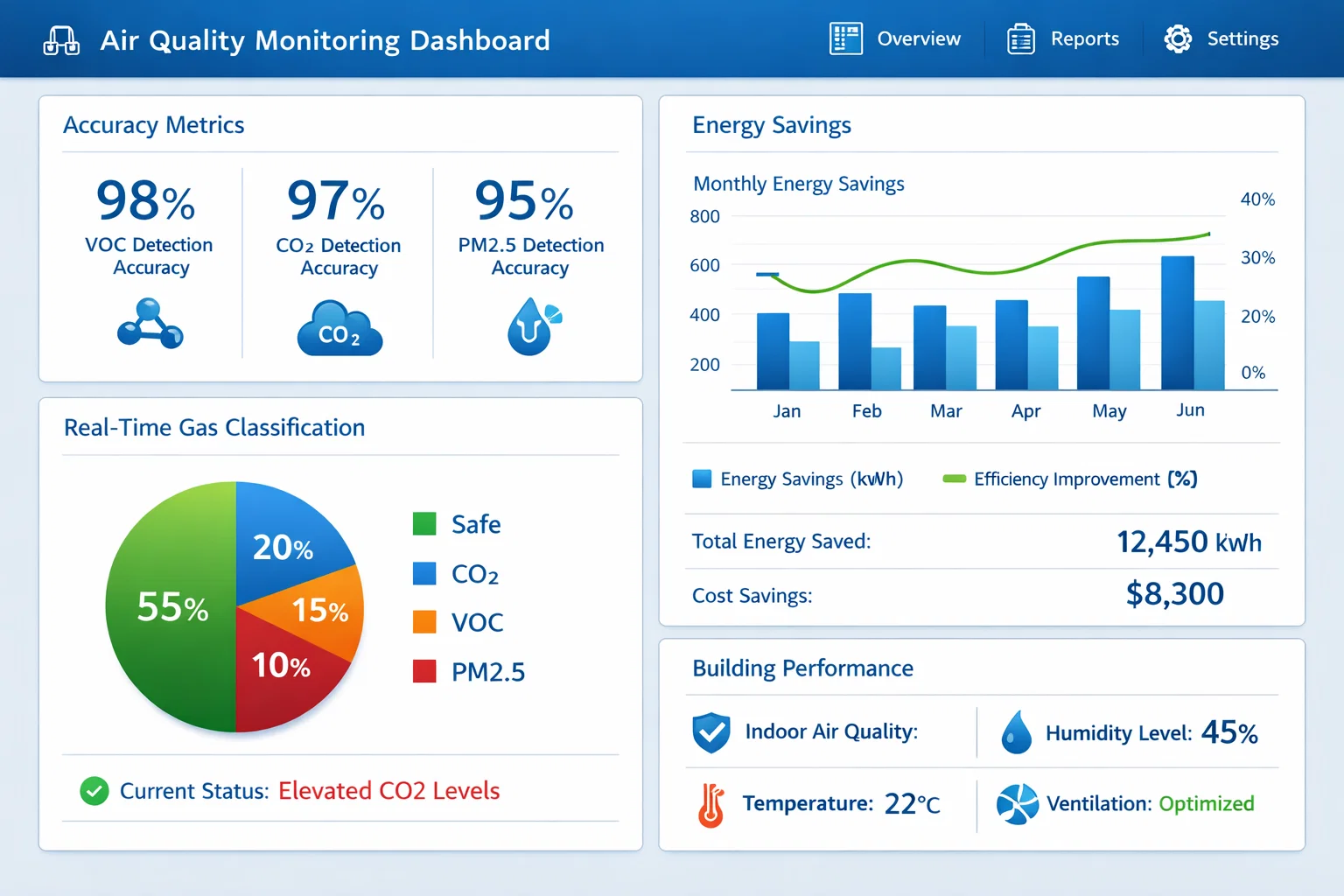

Energy Optimization Results:

Recent implementations show significant improvements:

- 15-25% energy savings through predictive control

- 17.4% reduction in HVAC runtime through occupancy detection

- 40% improvement in air quality response time

Smart Building Features:

- Preemptive Air Cleaning: Detect pollution sources before occupants notice

- Zone-Based Control: Adjust ventilation per room based on actual usage

- Predictive Maintenance: Monitor air filter efficiency through particle detection

- Emergency Response: Rapid detection of gas leaks or fire conditions

Real-World Implementation Challenges

Sensor Calibration and Drift Compensation

Gas sensors face several practical challenges in deployment:

Environmental Drift:

Metal-oxide sensors experience baseline drift due to:

- Temperature and humidity variations

- Sensor aging over 6-12 months

- Cross-sensitivity to interfering gases

Compensation Strategies:

1. Automatic Baseline Correction (ABC):

- Continuous background monitoring during unoccupied periods

- Polynomial curve fitting for gradual drift correction

- Environmental parameter compensation matrices

2. Machine Learning Drift Compensation:

# Pseudo-code for drift correction

def compensate_sensor_drift(raw_reading, environmental_data, time_series):

# Apply environmental corrections

temp_corrected = apply_temperature_correction(raw_reading, environmental_data.temperature)

humidity_corrected = apply_humidity_correction(temp_corrected, environmental_data.humidity)

# Time-series drift modeling

baseline_drift = predict_drift_kalman_filter(time_series)

return humidity_corrected - baseline_drift

3. Cross-Validation with Reference Standards:

- Periodic validation against certified reference gases

- Statistical process control for drift detection

- Automated recalibration scheduling

Field Deployment Considerations:

- Sensor Stabilization: 24-48 hour burn-in period for new installations

- Placement Strategy: Avoid direct airflow, heat sources, and contamination sources

- Maintenance Scheduling: Quarterly performance validation and annual recalibration

Performance Results and Validation

Measurable Outcomes

Classification Accuracy:

- Gas Source Identification: 92% accuracy across 8 common indoor gas sources

- Occupancy Detection: 94% accuracy using sensor fusion vs. 78% single-sensor

- Air Quality Prediction: 89% correlation with reference instrumentation

System Performance:

- Response Time: <30 seconds for gas classification changes

- Power Efficiency: 48-hour battery operation in low-power mode

- Communication Reliability: 99.7% FDCAN message delivery rate

Advancing Intelligent Monitoring

This air quality monitoring work directly strengthens Hoomanely's mission of revolutionary health monitoring through intelligent sensor systems. The multi-sensor fusion techniques, edge AI deployment strategies, and predictive analytics developed for environmental monitoring translate directly to pet health applications.

Shared Technology Foundations:

Edge AI + Sensor Fusion: Both air quality and pet health monitoring require real-time processing of multiple sensor streams to extract meaningful patterns from complex environmental data.

Predictive Intelligence: The same machine learning approaches that predict HVAC needs from air quality patterns can identify health trends from physiological monitoring data.

Physical Intelligence Ecosystem: The system architecture and multi-device coordination concepts proven in building automation enhance Hoomanely's interconnected smart device strategy.

Just as this air quality system shifts from reactive detection to predictive environmental control, Hoomanely transforms pet healthcare from reactive treatment to preventive wellness monitoring. The continuous data collection, pattern recognition, and personalized insights that optimize building environments directly parallel the technologies that enable hyper-personalized pet health intelligence.

This work validates the core technological foundations that make Hoomanely's vision of clinical-grade, continuous health monitoring achievable in real-world deployments.

Key Takeaways

Technical Achievements:

- Neural gas sensing enables gas source classification beyond simple concentration measurements

- Multi-sensor fusion improves accuracy by 15-20% over single-sensor approaches

- Edge AI deployment provides real-time intelligence without cloud dependencies

- FDCAN integration enables seamless building automation connectivity

Implementation Insights:

- Gas fingerprinting requires 24-48 hours of training data per environmental condition

- Sensor drift compensation is critical for long-term deployment success

- Edge AI optimization can achieve 400KB memory footprint with 2.6ms inference time

- Building automation integration provides immediate ROI through energy savings

Future Directions:

The convergence of AI-powered sensing, edge computing, and building automation creates opportunities for truly intelligent environments that adapt to occupant needs while optimizing energy efficiency. This foundation technology enables next-generation applications from smart homes to industrial monitoring systems.