Coatings and Finishes: Engineering Surfaces That Endure Real Life

Introduction: The Surface Is the Product

In consumer hardware, surfaces are often treated as cosmetic decisions—colour, gloss, texture. In reality, surface engineering is one of the most critical determinants of product longevity, safety, and trust. For products that live in close proximity to pets, surfaces are not passive shells; they are active interfaces subjected to repeated contact, abrasion, moisture, chemicals, heat, and sunlight.

At Hoomanely, coatings and finishes are engineered as functional systems, not aesthetic afterthoughts. Every enclosure surface must remain pet-safe, food-safe where applicable, resistant to wear, stable under UV exposure, tolerant of household chemicals, and robust against internally generated heat. Achieving this balance requires a disciplined approach to material selection, surface treatments, and validation—long before a product ever reaches a user.

This article explores how we design, test, and refine surface finishes so that our products maintain their integrity and appearance across years of real-world use.

Designing for Wear: Repetition Is the Real Test

Contact Isn’t Occasional—It’s Continuous

Pet products experience a unique wear profile. Surfaces are touched repeatedly, often in the same locations, by paws, noses, food bowls, and cleaning tools. Unlike consumer electronics that may be handled intermittently, these products experience daily micro-abrasion.

For example, in feeding systems like EverBowl, contact points include:

- Food bowl seating areas

- Raised edges where bowls are lifted and replaced

- Surfaces exposed to sliding, rotation, and minor impacts

These interactions compound over time. A finish that looks pristine after a week may reveal gloss loss, micro-scratches, or texture smoothing after months.

Engineering for Controlled Degradation

Rather than chasing indestructible surfaces, we design for predictable aging:

- Textures that retain visual uniformity even as micro-abrasion occurs

- Matte finishes that mask wear better than high-gloss surfaces

- Grain directions that distribute abrasion rather than concentrate it

Surface roughness is carefully chosen—not too smooth to show scratches immediately, not too coarse to trap debris or bacteria. The goal is a surface that ages gracefully, maintaining both function and perceived quality.

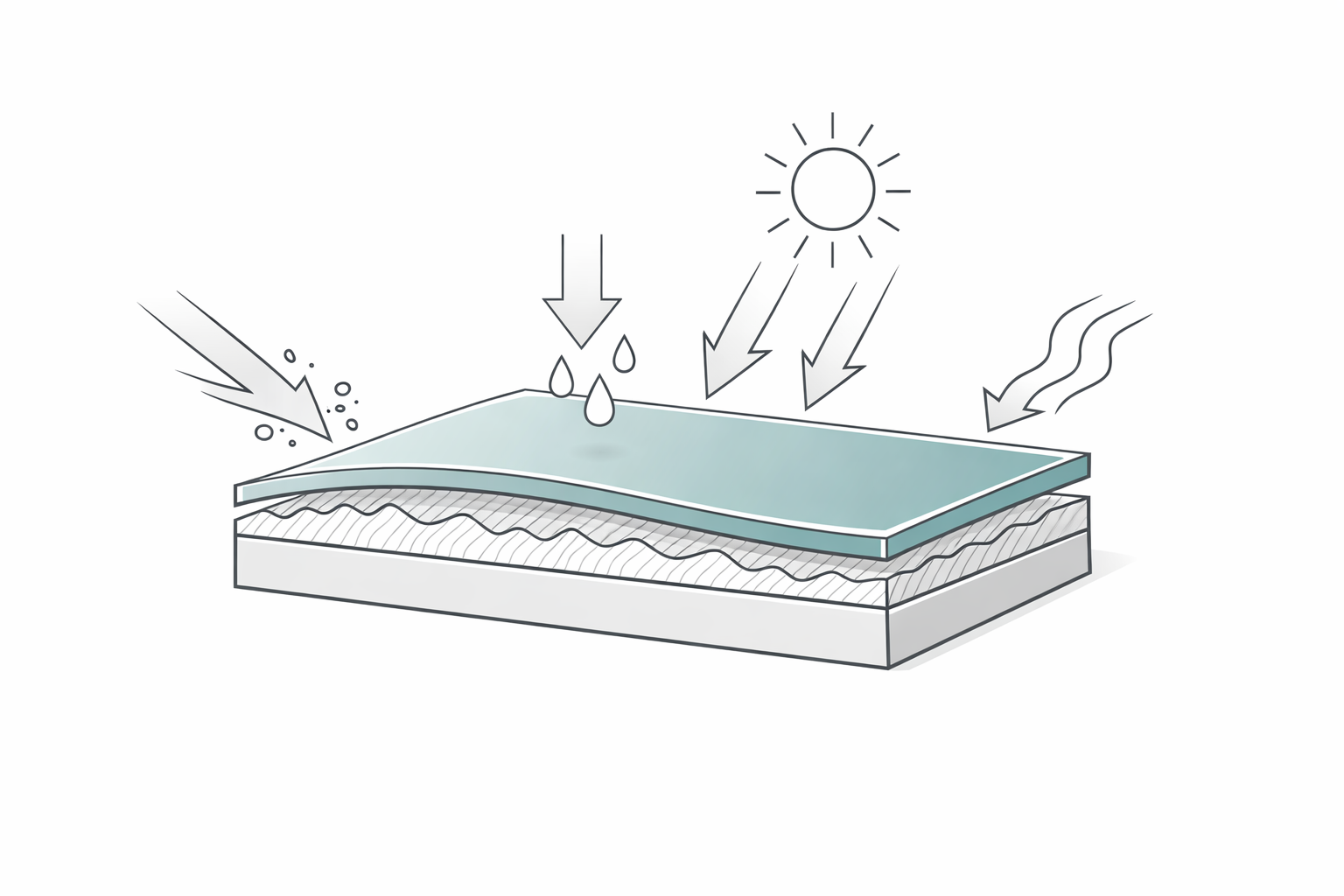

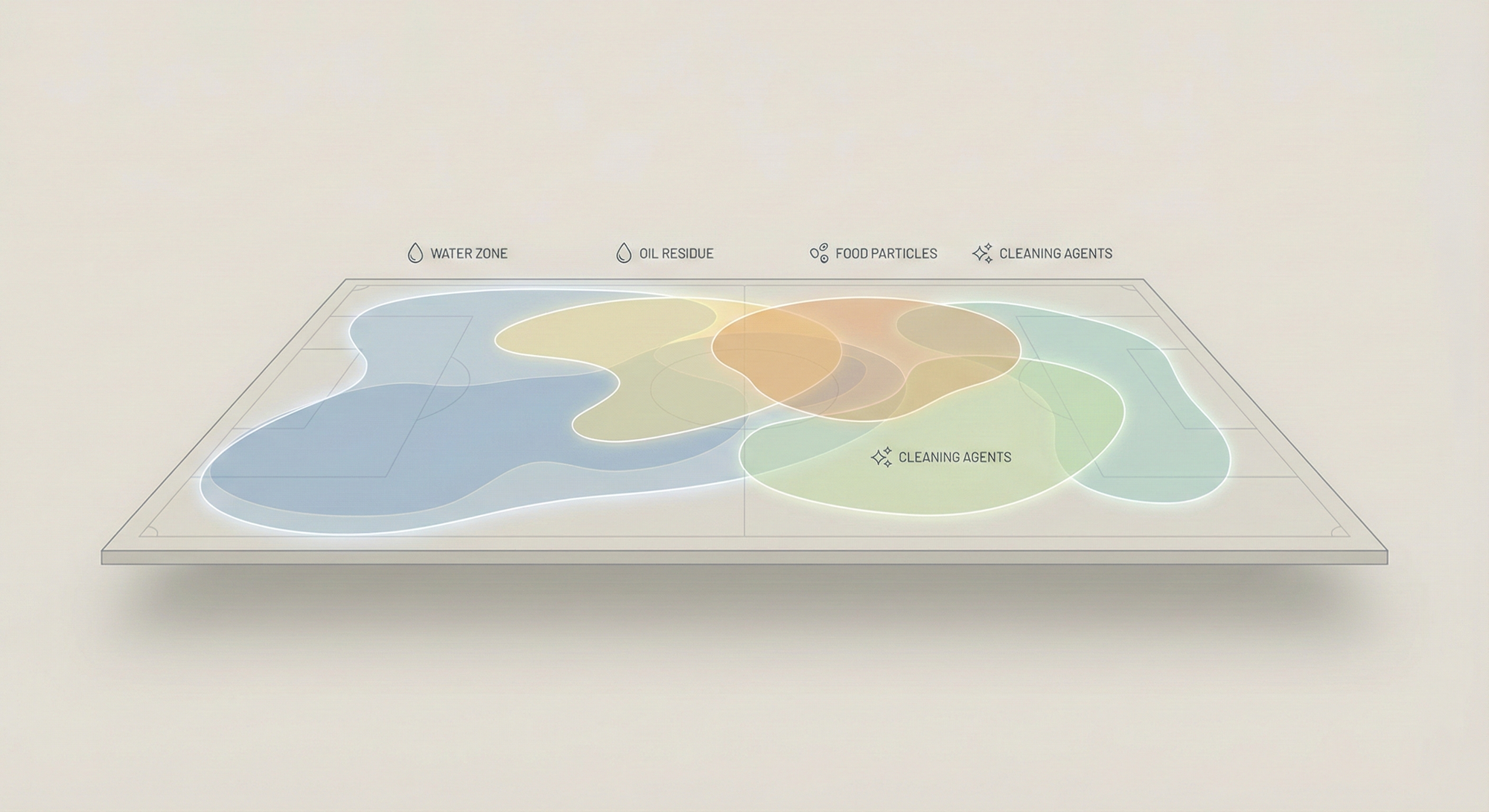

Chemical Resistance: Homes Are Harsh Environments

Food, Water, and Cleaning Agents

Household environments expose products to a wide spectrum of chemicals:

- Water with varying mineral content

- Food residues with fats, acids, and enzymes

- Pet saliva

- Cleaning agents ranging from mild soaps to alcohol-based sprays

For products like EverBowl, which are in constant contact with food and water, chemical compatibility becomes non-negotiable. Even trace reactions—surface whitening, softening, or discolouration—can compromise hygiene and trust.

Material and Coating Compatibility

We evaluate finishes not just in isolation, but in combination with expected substances:

- Resistance to oils and fats without surface swelling

- Stability against repeated wet-dry cycles

- No leaching or surface tackiness under exposure

Plastics, coatings, and surface treatments are assessed as systems. A coating that performs well on paper but interacts poorly with the base polymer is rejected early. Chemical stability over time matters more than initial appearance.

UV Exposure: The Invisible Degrader

Indoor Products Still See Sunlight

Even products designed for indoor use are exposed to UV radiation—through windows, balconies, or well-lit rooms. Over time, UV exposure can:

- Fade pigments

- Break down polymer chains

- Reduce surface toughness

- Introduce brittleness or chalking

This degradation is slow and often invisible until it becomes irreversible.

Designing for Colour and Structural Stability

Our surface strategy accounts for:

- UV-stable pigments rather than relying on surface colouration alone

- Base materials with inherent UV resistance where possible

- Finishes that block or diffuse UV rather than absorb it

Colour selection is informed by ageing behaviour, not just brand aesthetics. Subtle tonal shifts are acceptable; uneven fading or surface breakdown is not. A product should look intentionally aged—not prematurely worn.

Heat: The Quiet Internal Stressor

Electronics Shape Surface Longevity

Unlike static enclosures, modern products house active electronics. PCBs, processors, and power components generate heat that migrates into the enclosure. Over years of operation, this internal thermal load can:

- Accelerate polymer aging

- Alter surface hardness

- Reduce coating adhesion

- Cause localized discoloration

Heat is especially impactful where electronics sit close to cosmetic surfaces.

Thermal-Aware Surface Design

At Hoomanely, surface decisions are made alongside thermal design:

- Materials selected for thermal stability across operating ranges

- Coatings chosen for adhesion retention under cyclic heating

- Internal geometries that reduce direct heat transfer to cosmetic skins

Rather than insulating heat blindly, we manage its path—ensuring that cosmetic surfaces experience gradual, uniform temperature changes rather than hotspots.

Pet Safety: More Than Just Compliance

Touch, Taste, and Behaviour

Pets interact with products differently than humans. Surfaces may be:

- Licked

- Chewed

- Rubbed against repeatedly

This elevates requirements beyond basic consumer safety. Materials must be non-toxic, finishes must not flake or degrade into ingestible particles, and textures must not cause irritation.

Surface Engineering With Empathy

We prioritize:

- Finishes that remain inert under moisture and saliva

- No sharp texture transitions that could trap debris or bacteria

- Surfaces that are easy to clean without aggressive chemicals

Pet safety is not a checklist—it is a design philosophy that informs every material and finish choice.

Validation Through Iteration, Not Assumption

Testing Beyond the Datasheet

Material datasheets provide starting points, not guarantees. Real-world performance emerges only through validation across combined stressors:

- Wear + moisture

- UV + heat

- Cleaning cycles + abrasion

We assess finishes under compound conditions, because that is how products are actually used.

Consistency Across Variants

As product families evolve, surface strategies must scale. A finish that works on one enclosure geometry must remain viable across revisions and variants. This consistency reduces user confusion, simplifies maintenance, and reinforces brand trust.

Aesthetic Longevity: How Products Age Matters

First Touch vs. Tenth Thousand Touch

User perception evolves. The first interaction defines expectations; long-term interaction defines loyalty. A surface that feels premium initially but degrades quickly undermines confidence—even if the electronics perform flawlessly.

We design finishes to:

- Retain tactile quality over time

- Avoid glossy wear patterns that highlight usage

- Maintain uniformity even under uneven handling

Longevity is aesthetic as much as structural.

Integration With Mechanical Design

Finishes Cannot Fix Poor Geometry

Surface performance is inseparable from mechanical design. Sharp edges, stress concentrations, or thin cosmetic walls can accelerate surface failure regardless of coating quality.

Our enclosure designs:

- Avoid unnecessary sharp transitions

- Distribute contact forces across broader areas

- Support coatings through stable substrates

Surface engineering and mechanical engineering move together—not sequentially.

Conclusion: Surfaces as Systems

Coatings and finishes are often described in terms of appearance. At Hoomanely, they are engineered as systems that absorb wear, resist degradation, protect safety, and preserve trust.

By designing for abrasion, chemical exposure, UV radiation, and internal heat—simultaneously—we ensure that our products remain reliable and inviting throughout their lifecycle. This discipline transforms enclosures from disposable shells into durable interfaces between technology, pets, and people.

Longevity is not accidental. It is the result of deliberate material choices, informed testing, and an understanding that surfaces carry the story of a product’s life. When those surfaces endure, the product earns its place in everyday use—and that is the standard we design for.