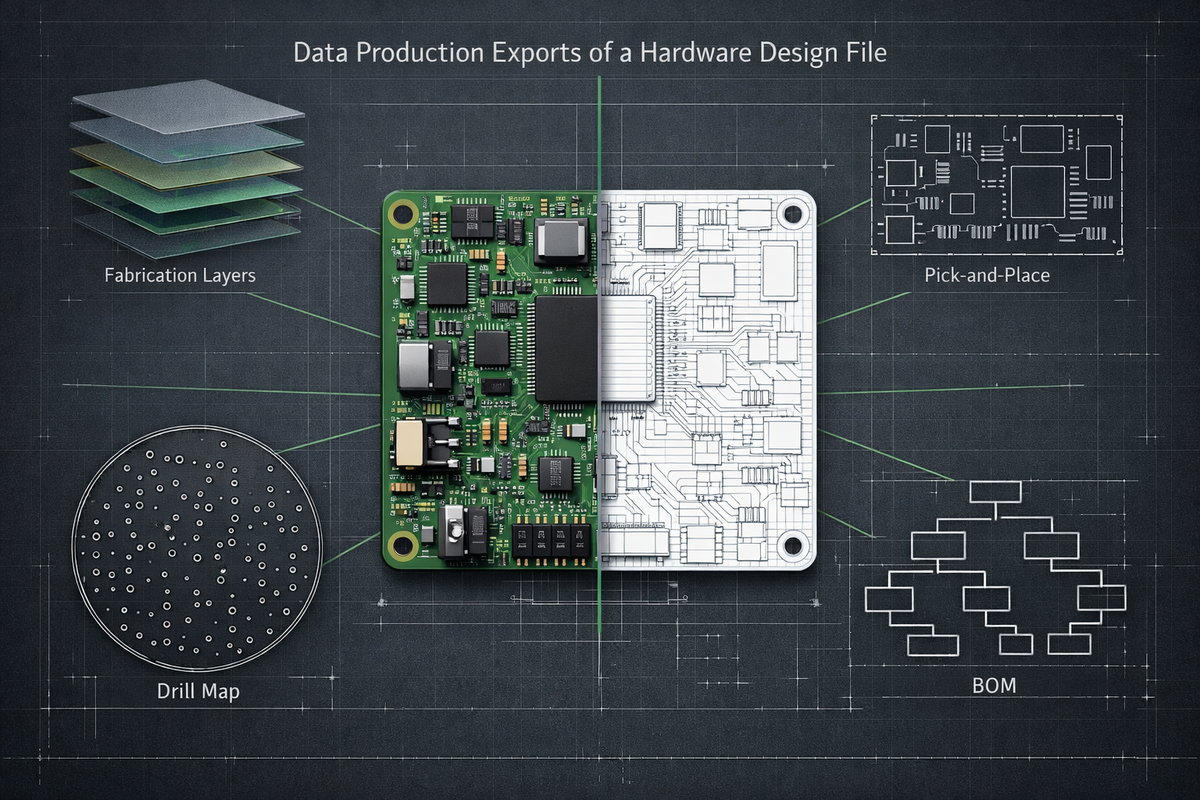

Data Production Exports of a Hardware Design File

Designing an Automated Handoff Between Engineering and Manufacturing

In hardware design, the moment a PCB layout is declared “done” is rarely the end of engineering. It is the beginning of translation.

What follows is not soldering irons or pick-and-place machines—it is data. Files. Formats. Assumptions. Naming conventions. Layer mappings. And the quiet but consequential act of turning a design intent into something a fabrication and assembly partner can act on with confidence.

At Hoomanely, we treat data production exports as a first-class design artefact. Not an afterthought. Not a checklist item at the end of a sprint. But a deliberately engineered interface between our internal design systems and the external manufacturing world.

This article explores how we approach automated fab and assembly handoff—why it matters, how it accelerates prototyping, and how disciplined export pipelines create a foundation for repeatable, vendor-agnostic hardware production.

The Invisible Bottleneck in Hardware Development

Modern PCB tools are powerful. They allow dense routing, complex constraints, multi-board projects, and rapid iteration. Yet despite this sophistication, many hardware teams still rely on manual, designer-dependent steps when generating production files.

These steps often live in individual habits:

- Exporting Gerbers with remembered settings

- Manually generating drill files

- Copying pick-and-place outputs into shared folders

- Renaming files to match a vendor’s preference

- Creating assembly notes from memory

None of these steps is inherently difficult—but together, they introduce variability. And variability is the enemy of speed.

When data exports depend on who generated them, when they were generated, or which vendor is receiving them, friction appears. Prototyping slows. Communication expands. Context has to be re-explained.

We wanted a different model: a deterministic, automated export pipeline where every board handoff feels predictable—to both engineers and manufacturing partners.

Production Data as an Interface, Not a Dump

The core shift in mindset is simple:

Production data is not a file set.

It is an interface contract.

That contract defines:

- What information is provided

- In what structure

- With what guarantees of completeness and consistency

At Hoomanely, we design our export pipeline with the same care we apply to firmware interfaces or electrical specifications. The goal is that any PCB vendor, anywhere, can take the output and immediately begin fabrication or assembly—without interpretation, clarification, or reformatting.

This is not about optimising for a single manufacturer. It is about designing for compatibility by default.

Automation as an Architectural Choice

Automation in this context does not mean scripting for convenience. It means encoding intent.

Our hardware design flow treats production exports as a reproducible process:

- Inputs are version-controlled design files

- Outputs are deterministic manufacturing packages

- The same inputs always produce the same outputs

This approach removes ambiguity. It also decouples human memory from production correctness.

An engineer does not need to remember:

- Which layers to include

- Which coordinate origin to use

- Which file naming scheme does the vendor prefers

- Which units are expected

The system already knows.

This is especially powerful in a prototyping environment, where speed matters but correctness cannot be compromised. Automation allows us to move quickly without taking shortcuts.

Structuring the Production Export Package

A well-designed export package communicates more than geometry. It communicates intent.

Our production handoff is organised around clear functional groupings, rather than tool-specific artefacts.

Fabrication Data

This includes everything required to physically build the bare board:

- Layered artwork with unambiguous polarity

- Drill and routing data

- Board outline and mechanical definitions

- Stackup representation aligned to design intent

The key principle here is explicitness. Nothing is implied. Nothing is “standard unless noted.” The data stands on its own.

Assembly Data

Assembly is a different problem space, and the data reflects that:

- Pick-and-place outputs with consistent origins

- Rotation conventions that do not change per board

- Reference designators aligned with silkscreen intent

- Clear top/bottom separation

Because this data is generated automatically, orientation rules and coordinate systems remain stable across revisions—making assembly predictable even as the design evolves.

Bill of Materials

The BOM is not a spreadsheet export—it is a manufacturing artefact.

- Line items are normalised

- Variants are explicit

- Manufacturer and sourcing data is cleanly separated from design intent

This clarity allows assembly partners to move from data to action without follow-up questions.

Documentation Layer

Rather than embedding assumptions in emails or chat messages, we include a structured documentation layer:

- Readme files that describe package contents

- Clear revision identifiers

- Notes that explain design intent, where needed, not how to interpret the data

This documentation is generated as part of the pipeline—not written ad hoc.

Designing for Vendor Compatibility

One of the biggest advantages of automated exports is vendor neutrality.

PCB vendors differ in tooling, preferred formats, and internal workflows. Rather than tailoring exports for each partner, we design for the lowest common denominator of clarity.

This means:

- Using widely accepted file formats

- Avoiding proprietary dependencies

- Keeping naming schemes descriptive and stable

- Ensuring units, origins, and orientations are explicit

The result is that new vendors can be onboarded quickly. Prototypes can be sent to multiple partners in parallel. And manufacturing decisions do not force changes upstream in the design process.

Compatibility becomes a property of the system—not a negotiation.

Speed Without Fragility

The true value of automation reveals itself under iteration.

Hardware prototypes rarely stop at version one. Layouts evolve. Components change. Mechanical constraints shift. And each revision needs to move smoothly from design to production.

Because our export pipeline is deterministic:

- New revisions inherit the same structure

- Vendors see familiar packages every time

- Differences between versions are clear and localised

This stability allows rapid iteration without accumulating complexity. Engineers focus on improving the product—not re-explaining the data.

Speed emerges naturally when the system removes friction rather than compensating for it.

Human-Centered Automation

Despite the emphasis on automation, this approach is deeply human-centred.

Engineers benefit because:

- Cognitive load is reduced

- Fewer context switches are required

- Production readiness is not a stressful event

Manufacturing partners benefit because:

- Data is clean and consistent

- Assumptions are minimized

- Communication becomes efficient and focused

Automation does not remove people from the loop—it respects their time and expertise.

Production Readiness as a Continuous State

A subtle but important outcome of this approach is that production readiness becomes continuous.

At any point in the design cycle, a board can be exported and built. There is no special “final export mode.” No fragile last-minute step where everything suddenly matters more.

This changes how teams think about hardware development. Designs feel grounded. Decisions feel reversible. And prototypes feel closer to production-grade by default.

Conclusion: Designing the Handoff, Not Just the Board

At Hoomanely, we view data production exports as a natural extension of hardware design. They are not paperwork. They are not bureaucracy. They are the final expression of engineering clarity.

By automating fab and assembly handoff:

- Prototypes move faster

- Vendors engage more effectively

- Engineers stay focused on what matters

Most importantly, the system scales—not just in volume, but in confidence.

When production data is predictable, hardware development becomes calmer, faster, and more enjoyable. And that quiet reliability—much like a well-designed connector or power interface—is the mark of a system that was thoughtfully engineered end-to-end.