Designing for EMI from Day Zero — How We Engineer Certifiable Hardware at Hoomanely

In modern connected hardware — especially the kind we build at Hoomanely, where a single board includes radios, sensors, power switching, ADCs, cameras, and compute — one silent enemy keeps showing up in product timelines:

Electromagnetic Interference (EMI).

But here’s the twist: EMI is predictable.

When we design a PCB with EMI principles from revision zero, we remove uncertainty from certification, reduce debug time, and eliminate the risk of costly re-spins.

At Hoomanely, we don't fix EMI.

We engineer products so EMI never becomes a problem.

What EMI Actually Means in Hardware Product Design

Every trace that carries a fast signal radiates electromagnetic energy.

Every return path that detours around a gap becomes a loop antenna.

Every switching regulator, Wi-Fi module, and high-speed bus introduces broadband noise.

If not controlled, these tiny radiators interact with:

- your own sensors (intra-device interference),

- nearby electronics (inter-device interference),

- regulatory thresholds (FCC/CE/IC compliance).

Rather than chasing noise after the first certification failure, we embed electromagnetic behavior into our routing rules from the beginning.

At Hoomanely, EMI is treated as a design parameter, not a debugging phase.

The Four EMI Principles We Apply on Every Board

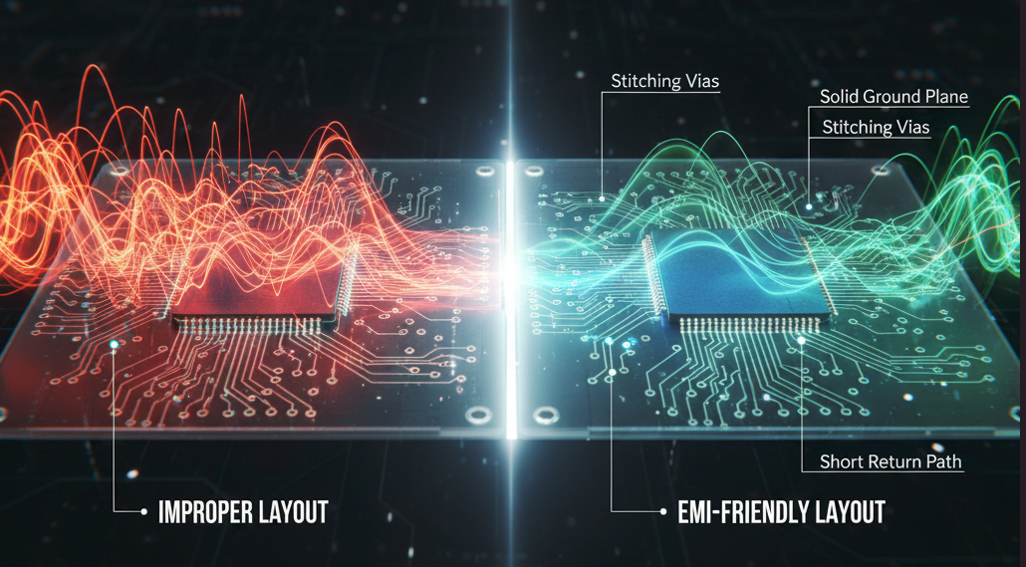

1. Stitching Vias — Creating Controlled Electromagnetic Boundaries

We place stitching vias extensively:

- Along board edges (forming a “ground cage”)

- Surrounding EMI-prone circuits (switching supplies, radios)

- Near transitions between signal layers to give return currents a direct path

Think of stitching vias as walls that contain high-frequency currents.

By spacing them roughly every 10–20mm (≈1/6th wavelength at digital harmonics), we reduce radiated emissions significantly.

Impact at Hoomanely:

This strategy has consistently improved radiated emission margins without requiring metal shielding cans — reducing BOM cost and simplifying mechanical assembly.

2. Solid Ground Planes — The Silent Hero of Signal Integrity and EMI

A PCB with a continuous ground plane behaves like a controlled RF environment.

| Feature | Benefit |

|---|---|

| Solid ground plane | Low-impedance return path & minimal loop area |

| Reduced segmentation | Prevents unpredictable return current detours |

| Acts as a shield | Contains electromagnetic fields internally |

3. Return Path Engineering — Controlling the Loop Area

A signal leaving an IC must return to the source — always.

At low frequencies, current follows the path of lowest resistance.

At high frequencies, current follows the path of lowest inductance — which means directly under the signal trace.

So we design for controlled return paths:

- High-speed traces always routed over an uninterrupted ground plane

- No ground gaps under USB, Ethernet, SPI, or clock lines

- Differential pairs tightly coupled to minimize loop area

EMI is proportional to loop area. Reduce the loop = reduce EMI.

This design discipline ensures USB/PCIe/Wi-Fi coexist without injecting noise into sensor analog paths.

4. Decoupling Network Strategy — Eliminating Noise at its Source

Instead of “placing capacitors near the pins,” we treat decoupling as localized energy absorption.

Rules we use:

- Caps placed within 3–5mm of IC pins

- Dedicated via to power plane and ground — no shared vias

- Multi-value capacitor stack (bulk + mid-frequency + high-frequency)

This ensures switching currents never travel far enough to radiate.

Good decoupling is the difference between a stable system and a noisy board.

Beyond EMI: The Engineering Advantages We Consistently See

When EMI is addressed from Day Zero:

| Advantage | Result |

|---|---|

| Faster certification | No redesign cycles, faster time to market |

| Better radio performance | Cleaner RF environment → higher sensitivity |

| Reliable sensor readings | No random noise-induced glitches |

| Reduced cost | No shielding cans, fewer filter components |

Teams that only aim to “pass EMI tests” stop at compliance.

We design for predictability, reliability, and scale.

The EMI Checklist Used at Hoomanely Before Sending a Board to Fabrication

Before a layout can be marked complete, it must pass this gate:

- Solid, uninterrupted ground plane

- Stitching vias every 10–20mm around edges

- Via fences around switching regulators and radios

- High-speed signals routed directly over ground plane

- No signal crossing that breaks ground return paths

- Decoupling caps within 3–5mm of IC power pins

- Differential pairs length- and impedance-matched

Final Thoughts

EMI-first design is not about avoiding failure.

It’s about engineering confidence.

PCB layout stops being guesswork and becomes a controlled, high-repeatability process. Radios behave predictably. Sensors stay clean. Certification becomes a formality.

At Hoomanely, EMI awareness is not a patch —

it’s baked into our engineering culture.