Designing for Light Pipes: Turning Photons into Product Experience

Introduction – The Small Window Users Notice First

A glowing icon on a device seems simple. Behind that glow lies a compact mechanical channel guiding light from an LED to the user’s eye. At product scale, this channel—the light pipe—becomes one of the most human-facing components in the entire design. It must translate raw electrical energy into precise optical output while fitting comfortably within tight enclosure envelopes.

Light pipes sit at the intersection of several constraints: LED placement on a PCB, enclosure tolerances, material choices, and optical budgets. In vBus modular products, where sub-parts are independently engineered, these interfaces grow even more important. Every module may be designed by a different engineer, yet the light pipe must behave identically across all of them.

This blog explores the engineering thinking that makes that possible—how Hoomanely approaches light pipes not as accessories, but as precision optical-mechanical systems that define clarity, consistency, and first impressions.

Why Light Pipes Matter

From a commercial and usability standpoint, illumination is often the first functional cue that a product is alive. Whether it is a smart bowl module, a gateway hub, or a sensor node, the user depends on light for:

- Power state indication

- Communication activity

- Alerts and errors

- Aesthetic brand identity

Unlike software features that live inside code, light pipes are literal windows into the product. Their effectiveness directly influences:

- Legibility in bright rooms

- Visibility from multiple viewing angles

- Perceived quality of the enclosure

- Assembly repeatability

A poorly designed light system can appear dim, misaligned, or inconsistent. A well-engineered one delivers confidence with every press of the button.

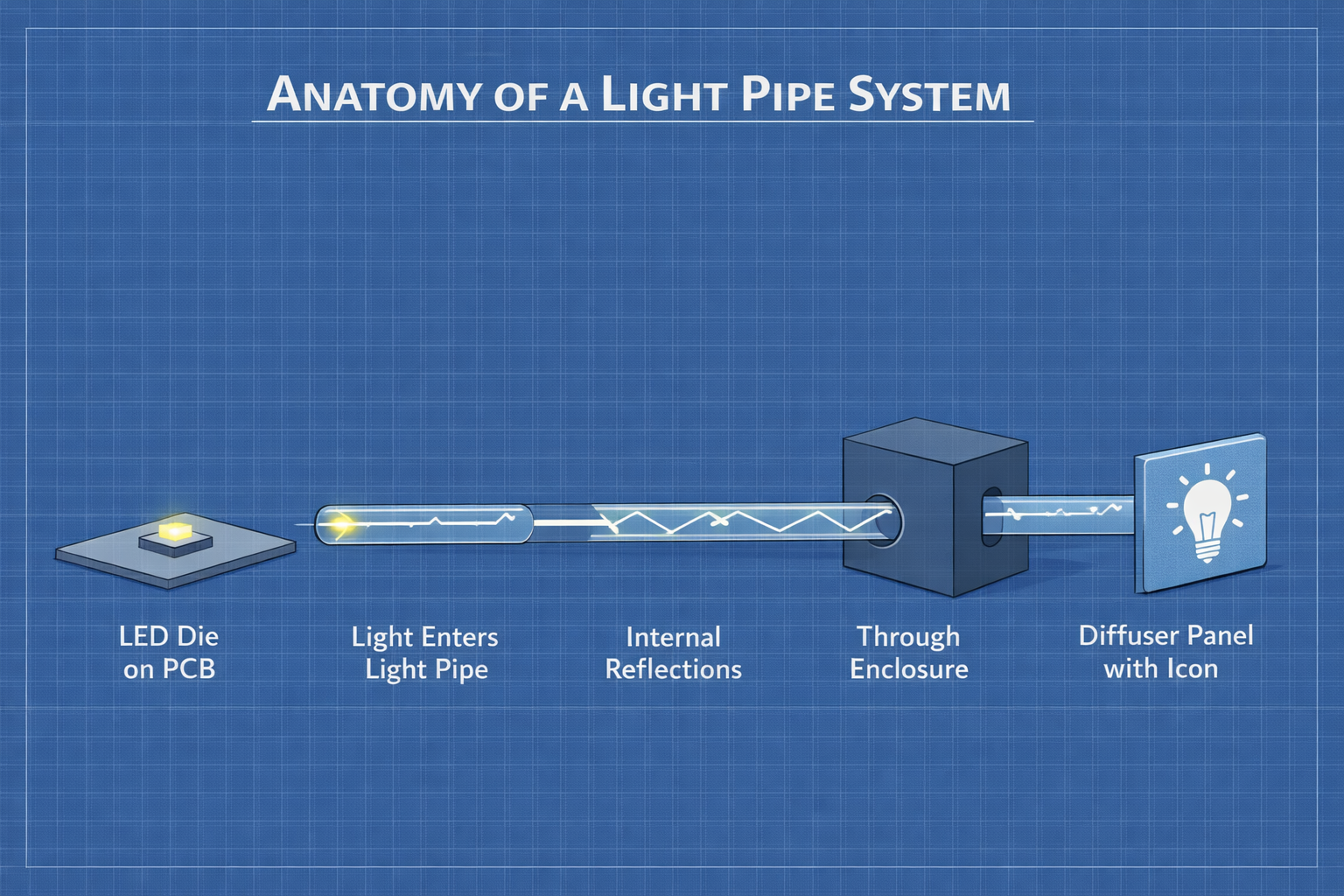

The Anatomy of a Light Pipe System

At its core, a light pipe performs three jobs:

- Collect light from an LED source

- Transmit it efficiently through a mechanical medium

- Deliver it to the exterior surface without loss or distortion

But in real products, the “system” includes far more:

- The LED (electrical source)

- PCB location (mechanical origin)

- Light pipe material

- Pipe geometry

- Enclosure opening

- Diffuser or icon

- Human eye as the final detector

Each of these stages must be engineered together.

Optical Budgets – Engineering the Brightness

Understanding Light as a Finite Resource

Every LED emits a fixed luminous flux. That flux is our optical income. The journey from LED die to enclosure face consumes portions of this income at each stage. The optical budget defines how much light survives.

At Hoomanely, optical budgets are built with the same seriousness as power trees.

Typical Loss Contributors:

| Stage | Typical Loss |

|---|---|

| LED package inefficiency | 5–10% |

| Air gap coupling | 10–20% |

| Light pipe absorption | 5–15% |

| Reflection losses | 5–10% |

| Diffuser attenuation | 20–40% |

The objective is clear: maximize the transmitted light while staying within acceptable electrical power limits and thermal considerations.

Designing the Optical Budget

To hit the right balance, engineers tune several variables:

- LED brightness selection: Higher mcd ratings for indicators meant to be viewed from distance.

- Material transparency: Polycarbonate or acrylic light guides with high optical clarity.

- Diffuser choice: Thinner diffusers for icons requiring brightness; heavier diffusers for aesthetic uniformity.

- Geometry efficiency: Shorter pipes with fewer bends for power indicators.

Key Principle:

The required brightness at the enclosure face should be achievable with a deliberate margin—typically 30–40% above minimum acceptable visibility.

This ensures that variations in components and environments don’t push the product into a dim or unreadable state.

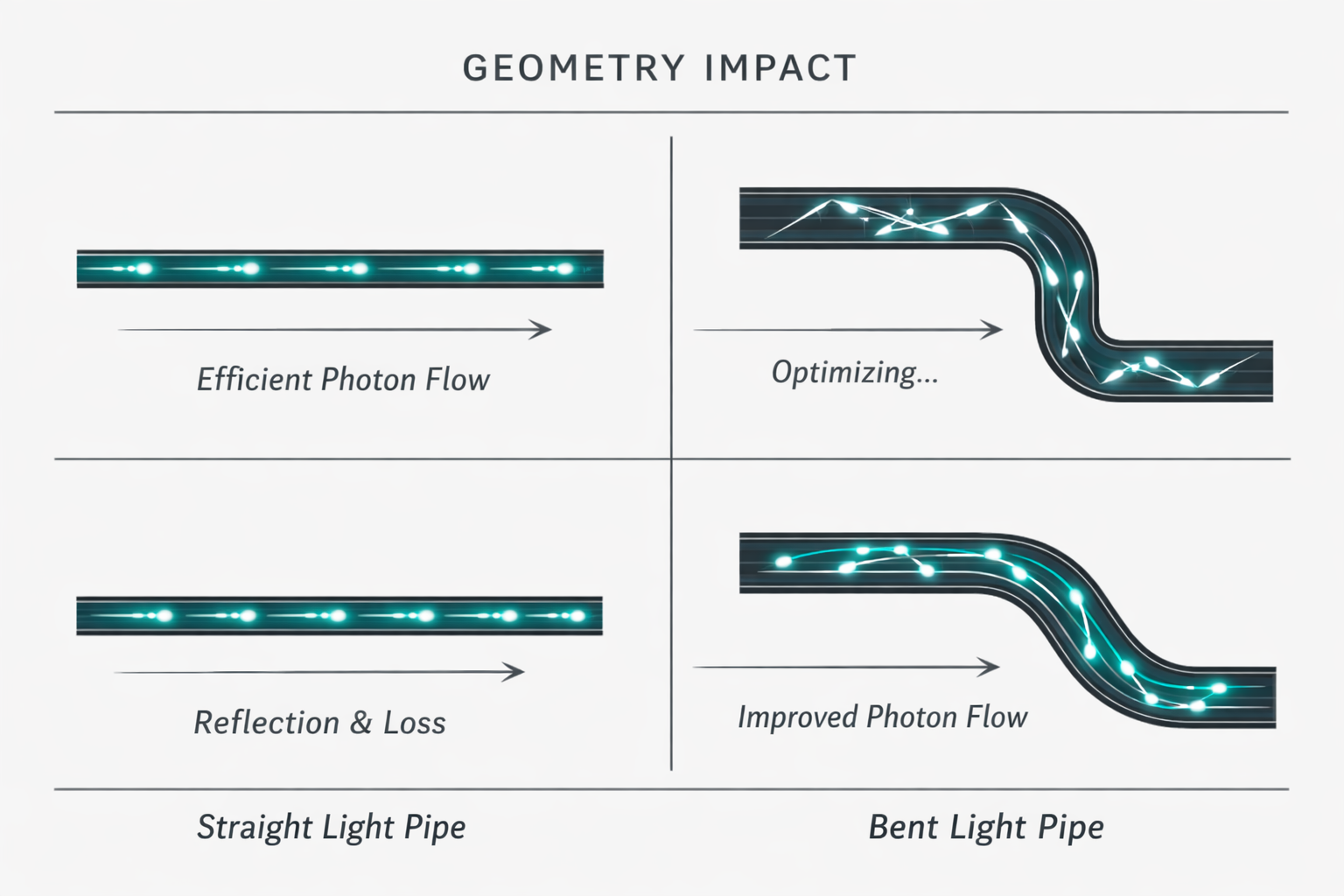

Geometry – The Path of Light

Straight vs Bent Light Pipes

Geometry is where mechanical design becomes the hero.

- Straight light pipes offer best efficiency and are preferred for simple power LEDs.

- Bent or multi-segment pipes are used when enclosure constraints prevent direct alignment.

Each bend introduces reflection inefficiency. Hoomanely designs include:

- Smooth radii bends

- Polished internal surfaces

- Reflective coatings when necessary

- Strategic mirroring of LEDs closer to enclosure walls

Design Insight:

When geometry becomes complex, LED placement is revisited rather than the pipe itself being forced to compensate.

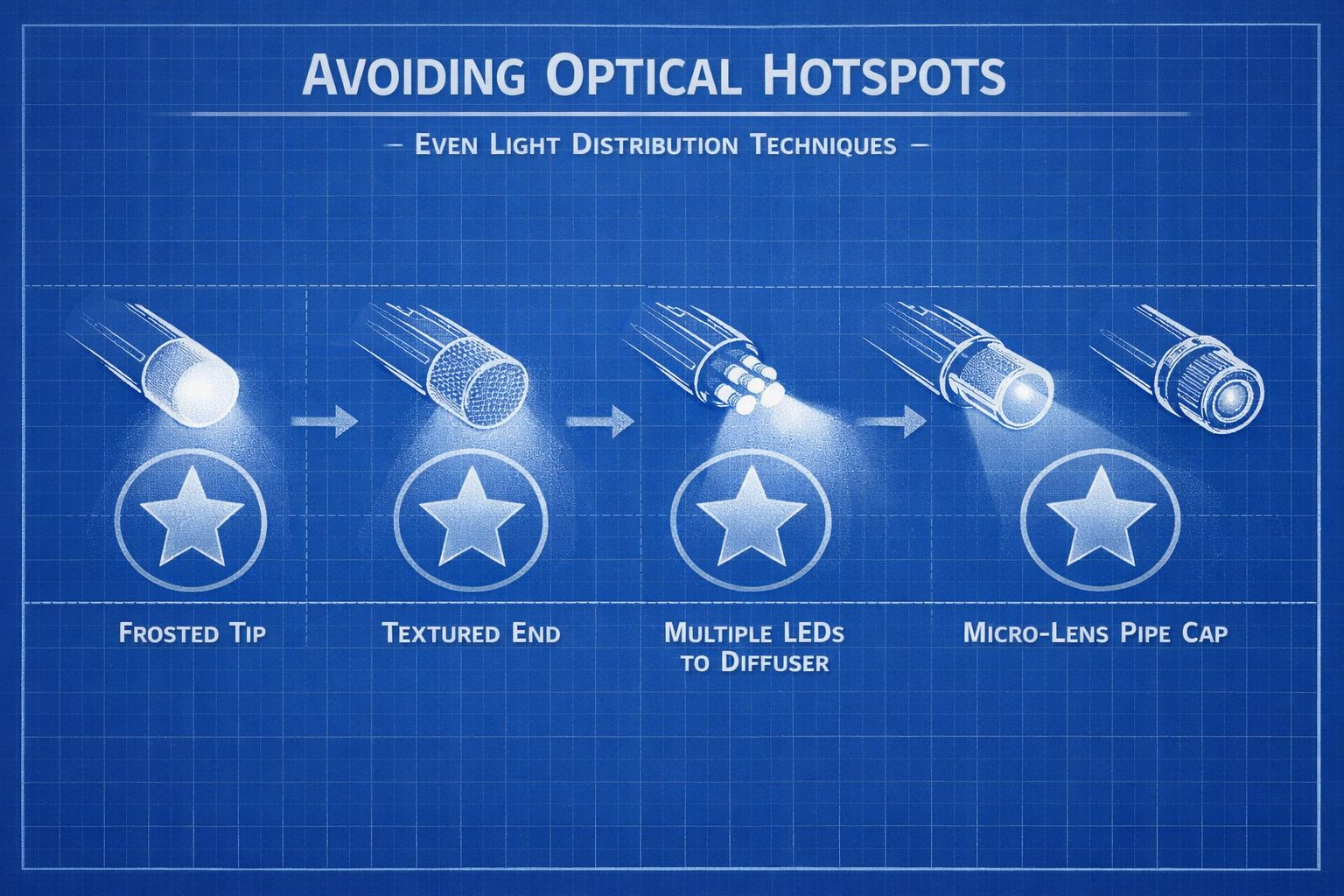

Avoiding Optical Hotspots

Uniform illumination matters for icons and front panels. Techniques include:

- Frosted pipe tips

- Textured ends

- Multiple LEDs feeding one diffuser

- Micro-lens structures

For multi-module systems like vBus, consistency across boards demands identical LED and pipe geometries.

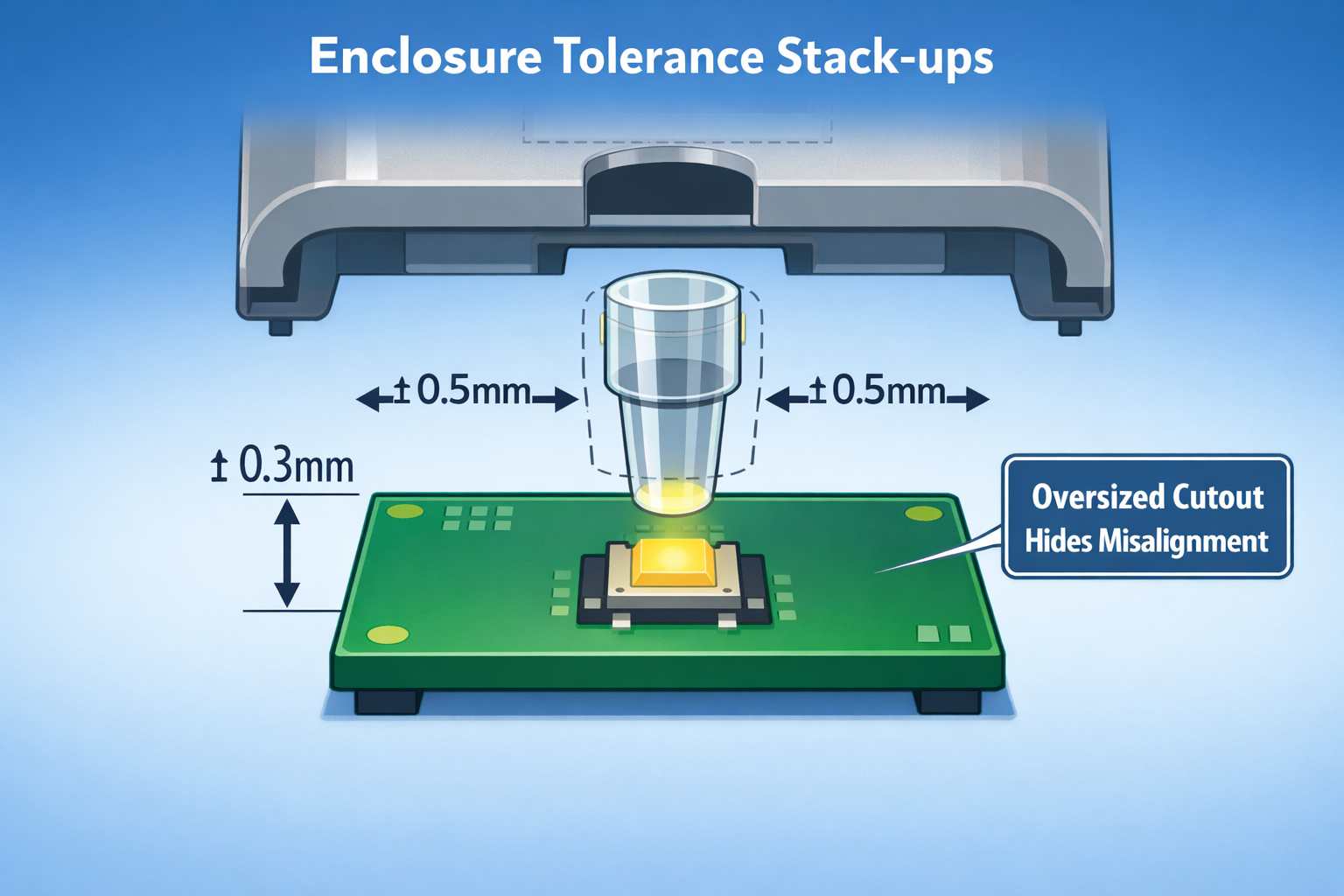

Enclosure Tolerances – Designing for Alignment Reality

The Mechanical Challenge

The light pipe does not live alone—it must pass through a precisely cut opening in the product enclosure. This is where tolerance stack-ups can disrupt optical alignment.

Common Constraints:

- PCB placement tolerance: ±0.3mm

- Enclosure cutout tolerance: ±0.5mm

- Connector alignment shifts

- Assembly screw boss variations

These may seem small—but for a pipe delivering to a 3mm opening, they are enormous.

Engineering for Tolerance Stack-Ups

To handle this, Hoomanely designs include:

- Self-aligning light pipe housings that guide the pipe directly onto LED center after enclosure closure.

- Floating or compliant pipe mounts allowing minor lateral shifts without visible misalignment.

- Asymmetric shells that mechanically force correct orientation.

- Silicone gaskets around pipe interfaces to maintain both optical and moisture integrity.

Designers assume that the enclosure will vary. Therefore:

The opening on the enclosure is always designed larger than the pipe tip with a controlled shadowing zone—so misalignment stays invisible to users.

Connector Influence

vBus connectors often anchor PCBs at known positions. We ensure:

- Pipe tip alignment considers connector datum

- Avoid pipes in zones of mechanical stress

- Place LEDs near rigid anchoring points

Material Choices – The Optical Transmission Medium

Selecting the Right Plastic

Light pipes are made primarily from:

- Acrylic (PMMA)

- Polycarbonate (PC)

- Clear ABS

Each material brings different characteristics:

| Property | Acrylic | Polycarbonate |

|---|---|---|

| Transparency | Excellent | Very good |

| Impact resistance | Moderate | Excellent |

| Heat tolerance | Good | Better |

| Moisture absorption | Low | Low |

| Rework/assembly ease | High | High |

For consumer environments, polycarbonate becomes the preferred choice because it balances clarity with mechanical robustness.

Thermal Behavior of Pipes

Material must also survive heat from LEDs:

- Heat-resistant plastics prevent discoloration

- Shorter pipes reduce exposure

- Black masking paint around LEDs prevents light bleed into unintended regions

PCB Considerations – Where Electronics Serve Optics

Even though this blog is not about tutorials, several PCB-level considerations remain central:

- LED orientation must be standardised

- LEDs placed at predictable datum points

- Avoid vias or tall components between LED and pipe

- Use high-contrast soldermask under diffusers to avoid reflection artefacts

This allows every PCB variant to integrate seamlessly with identical light pipes.

Design Validation – Optical Characterisation

Measuring Light Output

Optical validation ensures design intent is met:

- Light meter readings at the enclosure face

- Angular visibility testing

- Bright room vs dark room characterisation

- Thermal drift visibility (LED and pipe under temperature rise)

The goal is not just “does it light up?” but:

Is the optical budget maintained across all mechanical and environmental conditions?

Multi-Angle UX – Designing for Human Perception

Light pipes must serve human eyes in real environments:

- Viewing distance: 30cm to 3 meters

- Angle of view: 0° to 75°

- Legibility under glare

- Consistency across product SKUs

We design for:

- Daytime legibility

- Nighttime softness

- Color uniformity

- Graceful alerts

This makes illumination both reliable and delightful.

Manufacturing Jigs – Enabling Optical Consistency

Jigs also play a crucial role:

- Test jigs ensure LED positions are precise

- Enclosure jigs hold openings consistently

- Assembly jigs prevent stress on pipes during closure

These processes ensure every assembled board presents an identical optical output to the user.

Where Geometry Fights Light Bleed

Optical Isolation

When multiple LEDs exist on a board:

- Dedicated internal chambers

- Pipe-to-LED guard walls

- Black conformal masking zones

- Diffuser partitions

This prevents photons from straying into unintended icons or windows.

Aging and Aesthetics

Longevity concerns include:

- Pipe discoloration

- Scratches on diffuser surfaces

- LED brightness aging

By designing pipes as replaceable sub-parts, aesthetic refresh becomes possible on new revisions.

Cost Considerations – Balancing Electrical, Mechanical, Optical

Engineers balance:

- LED cost vs pipe efficiency

- Diffuser thickness vs brightness

- Enclosure machining vs compliance

Small investments in optics reduce large costs in rework and support.

Diagrams – Where They Fit Best

In the blog, diagrams are ideally added:

- After the Optical Budget Section

- After Enclosure Tolerance Section

- Before Manufacturing Jigs Section

- Just before the conclusion

These visual anchors reinforce the optical-mechanical story.

Conclusion – Guiding Light, Guiding Confidence

Light pipes are modest components with enormous impact. They deliver more than illumination—they deliver confidence, clarity, and first impressions. Designing them demands thoughtful attention to budgets, geometry, materials, and tolerances.

At Hoomanely, we’ve elevated light pipe design to first-class discipline. Every module we ship demonstrates that intuitive interaction backed by rigorous optical-mechanical engineering creates products that feel reliable and look delightful simultaneously.

When electrons, plastics, and photons are engineered together, the glow users see is more than a light—it is the visible proof of design quality.