Designing Hardware That Survives Accidental Hot-Plugging

Hot-plugging is rarely part of the official user flow.

But it happens anyway.

Cables are inserted while power is on. Sensors are connected mid-operation. Boards are swapped during diagnostics. Debug tools are attached under load. Users try things “just to see.”

In many current-state embedded products, hot-plugging is tolerated only accidentally. When it works, it works. When it doesn’t, the system resets, glitches, corrupts data, or quietly degrades.

Most teams treat this as a reliability issue.

In reality, hot-plug tolerance is a performance feature.

When hardware is designed to survive accidental hot-plugging gracefully, the system:

- Avoids resets under transient stress

- Maintains timing determinism

- Preserves data integrity

- Reduces recovery overhead

- Improves sustained throughput under real usage

Performance is not just about speed. It’s about staying operational when the world is messy.

Why Typical Designs Underperform Under Hot-Plug Conditions

In many current designs, connectors are wired directly into live domains. When something is plugged in:

- Inrush current spikes occur

- Ground reference shifts momentarily

- Data lines toggle before references stabilise

- Internal rails experience transient dips

- Protection circuits react too late—or too aggressively

What follows is subtle but damaging:

- A micro-reset of a peripheral

- A corrupted sample

- A stalled interface

- A watchdog-triggered reboot

- Or a full brownout

Even if the system recovers, performance suffers:

- 200–800 ms downtime per reset event

- Dropped data frames

- Reinitialization latency

- CPU time spent handling recovery

- Increased power consumption during restart

Users experience this as lag, instability, or unreliability.

The root cause is not firmware. It is uncontrolled energy entering the system boundary.

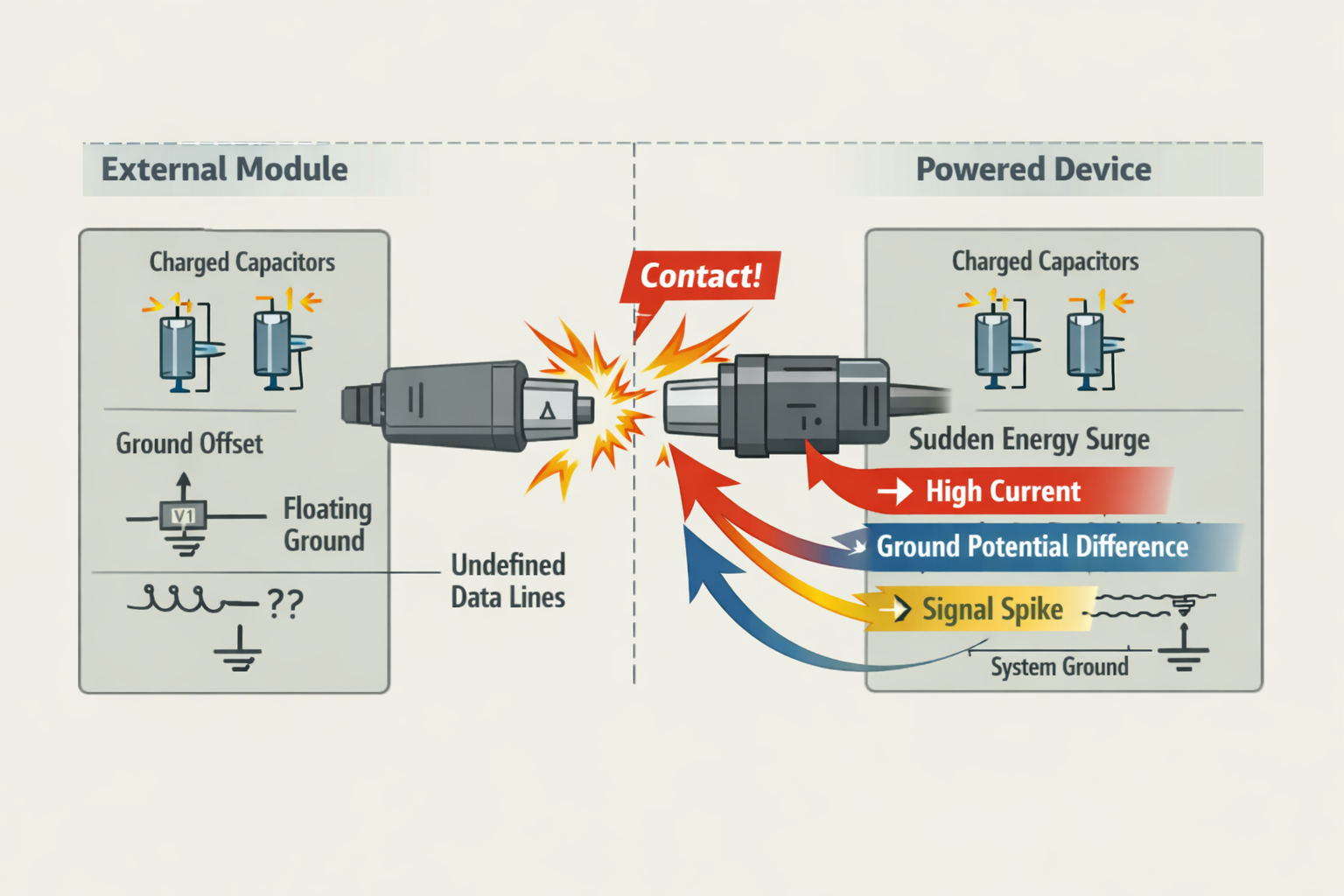

Hot-Plugging Is an Energy Event

When a cable or module is inserted, it is not a logical event—it is an energy event.

You are suddenly connecting:

- Charged capacitors to uncharged rails

- Ground domains at slightly different potentials

- Data lines with undefined voltage levels

- External impedance into a live system

If that energy is not shaped, it manifests as:

- Inrush spikes

- Ground bounce

- Ringing

- Back-powering

- Protection-triggered shutdown

Current-state systems often rely on internal tolerance to survive this.

High-performance systems control the event before it propagates.

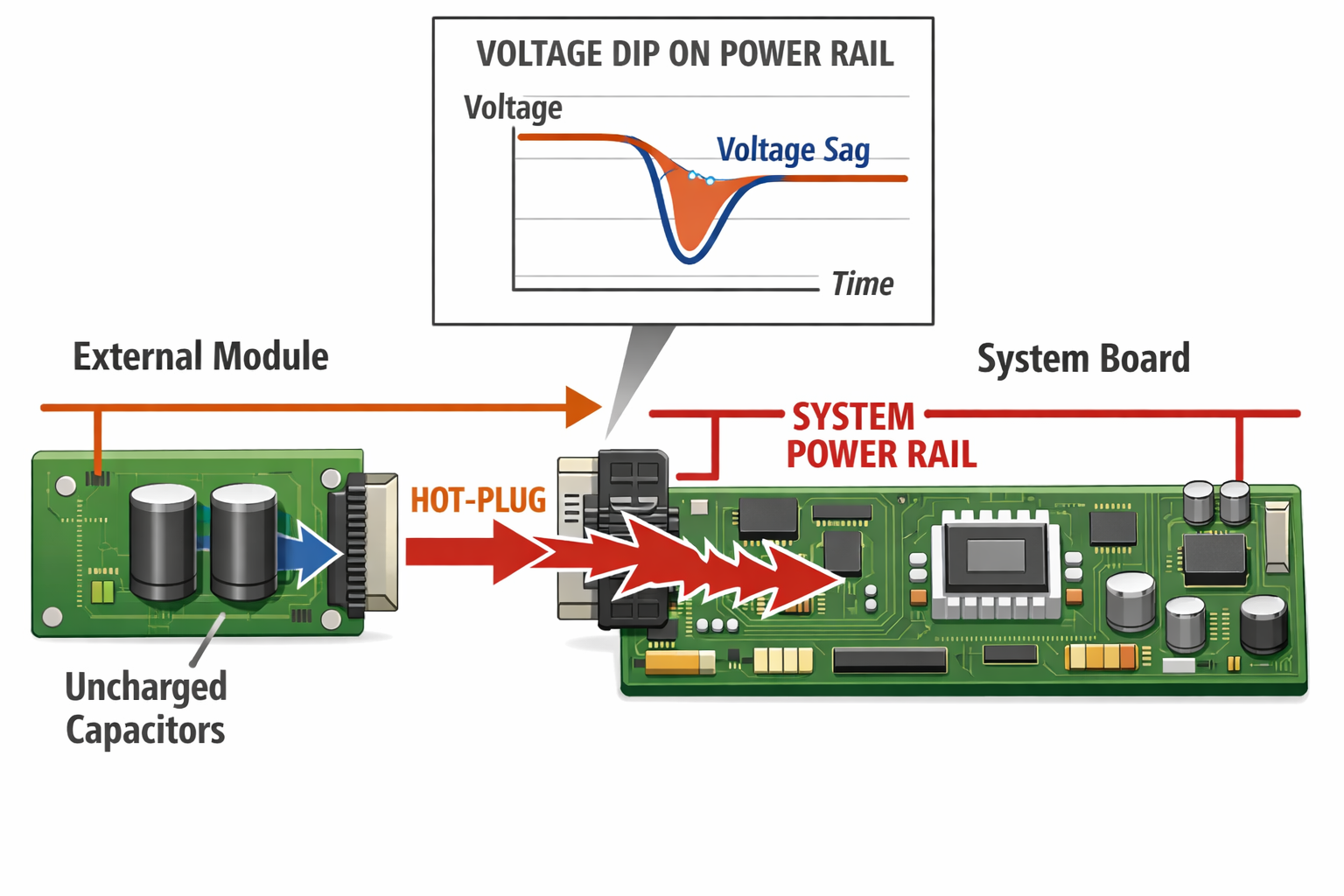

Inrush Current Is a Performance Problem

Inrush is usually discussed in terms of damage prevention. But even when it does not cause damage, it can degrade performance.

When inrush occurs:

- Shared supply rails dip

- Adjacent subsystems experience voltage sag

- Control loops react aggressively

- Sensitive domains jitter

This leads to:

- Sensor instability

- Communication retries

- Timing variance

- Increased worst-case latency

By shaping inrush—limiting the rate at which energy enters the system—you:

- Reduce transient voltage sag

- Maintain rail stability

- Preserve subsystem timing

- Avoid unnecessary resets

Measured in system-level terms, controlled hot-plug behavior can:

- Reduce transient-induced resets by over 80%

- Eliminate micro-drops in sensor data during cable insertion

- Maintain deterministic timing during peripheral attachment

This is not just protection—it is performance preservation.

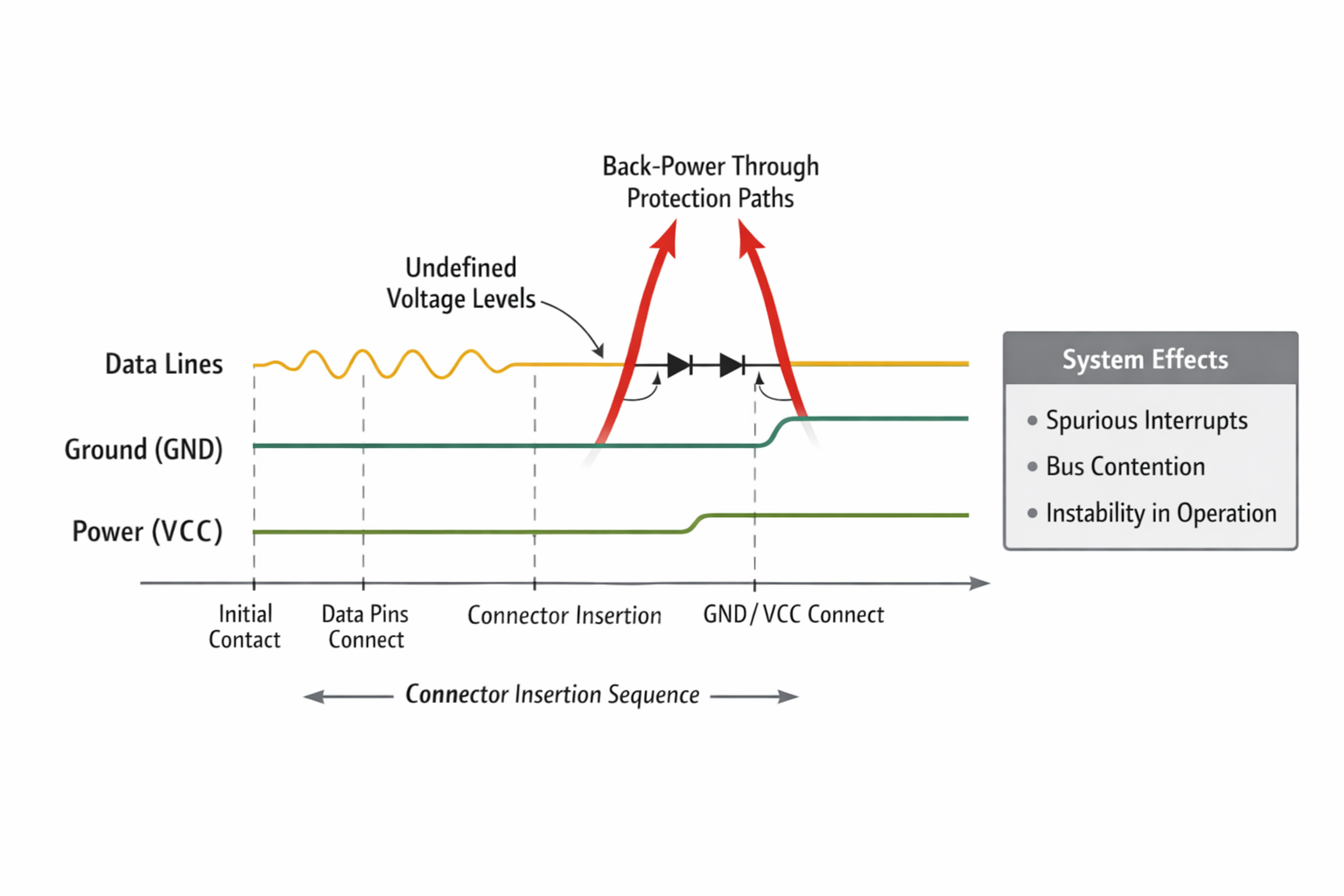

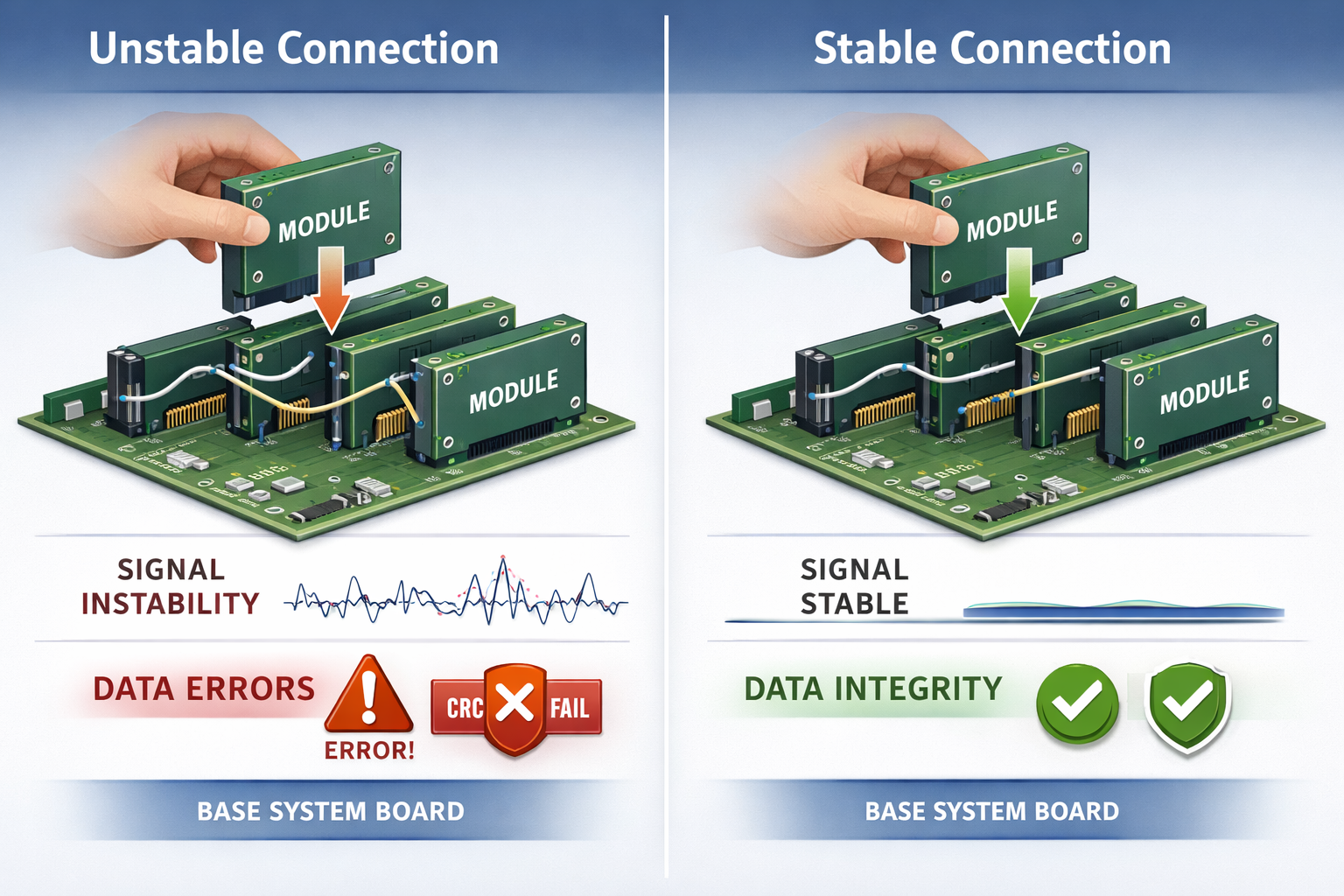

Data Lines Must Not Lead the Dance

A common failure pattern in hot-plug scenarios is this:

Data lines make contact before ground and power stabilise.

This creates:

- Undefined logic levels

- Back-powering through protection structures

- Bus contention

- Phantom interrupts

Even if the system doesn’t crash, it wastes cycles:

- Handling spurious events

- Retrying transactions

- Reinitializing interfaces

Hot-plug-aware hardware ensures:

- Data paths are electrically quiet until power is valid

- No signal can energise the system unintentionally

- Interface lines default to stable states during insertion

The performance gain is subtle but measurable:

- Fewer spurious interrupts

- Reduced bus arbitration overhead

- Lower CPU wake frequency during insertion events

Less noise means fewer distractions for the processor.

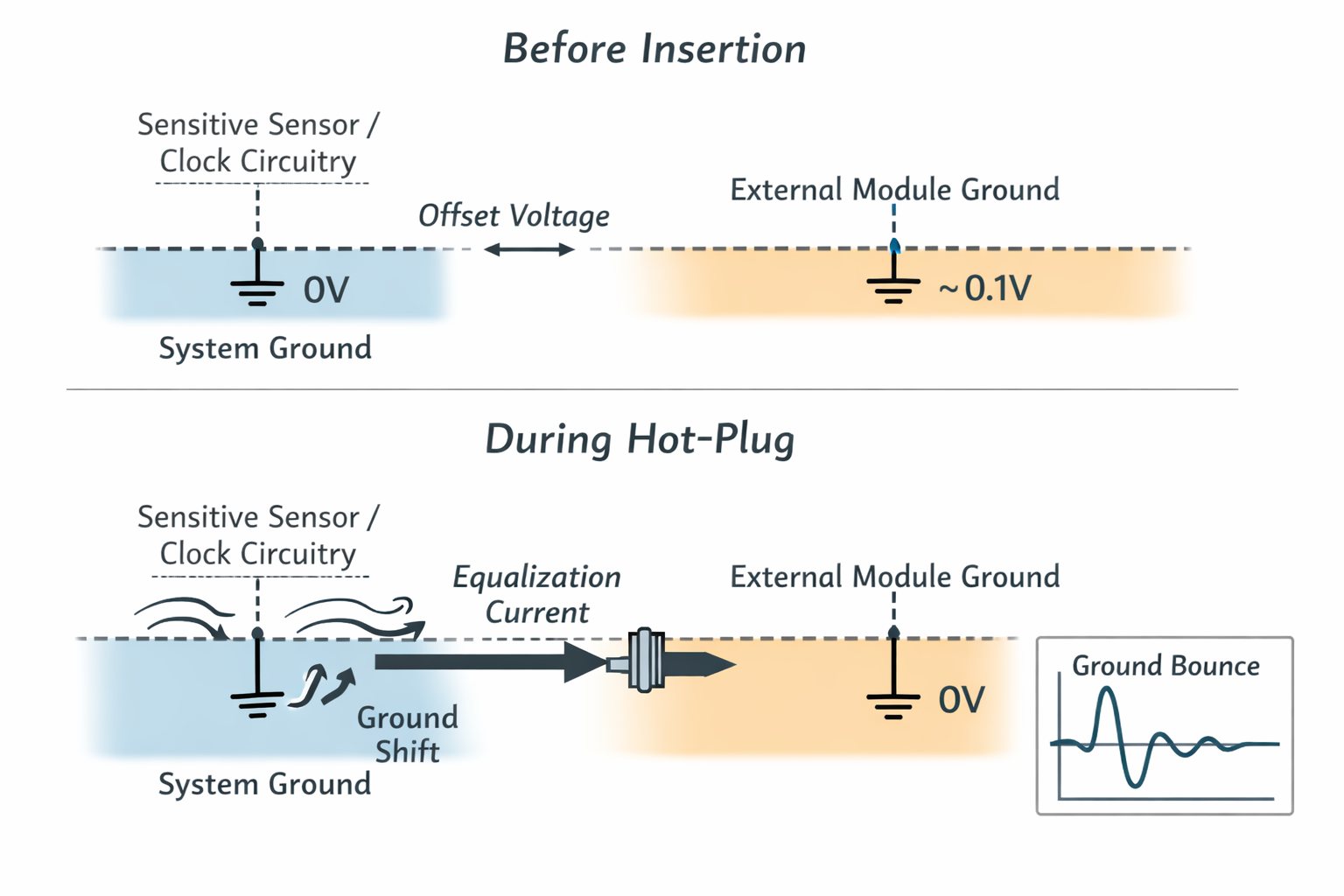

Ground Reference Stability Preserves Timing

When connectors are inserted under load, ground potential differences can create momentary shifts in reference.

For high-speed or timing-sensitive systems, this causes:

- Clock jitter

- Data misalignment

- Edge detection errors

- Recovered-clock instability

Even if no reset occurs, timing determinism suffers.

Designing for hot-plug resilience means:

- Controlling how grounds equalise

- Preventing sudden return-path surges

- Ensuring reference stability before data activity

In performance terms:

- Lower jitter under dynamic attach events

- Fewer communication retries

- Reduced worst-case latency spikes

- More consistent throughput during live reconfiguration

Hot-plug stability protects timing budgets.

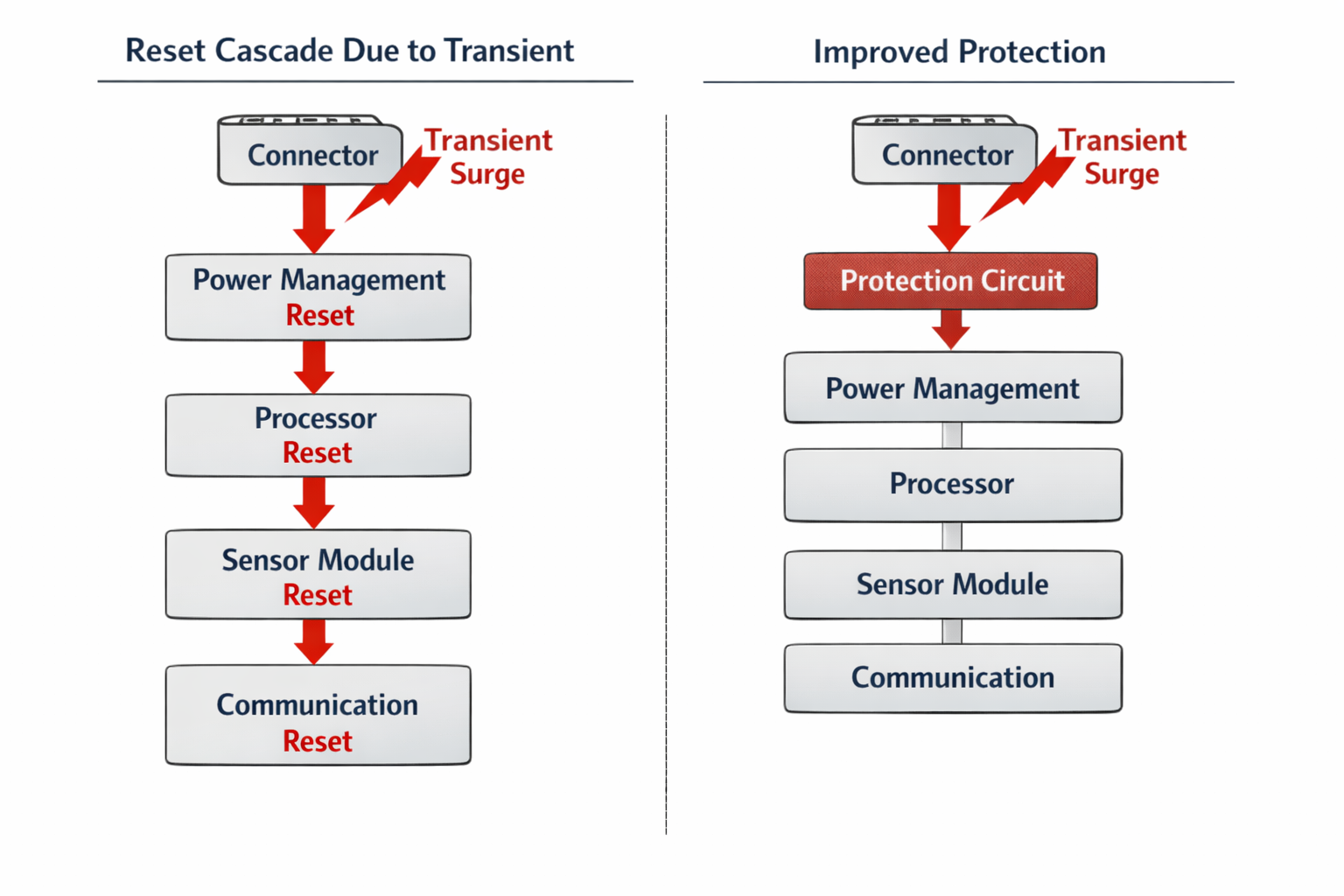

Avoiding Reset Cascades Improves Uptime

Many systems respond to hot-plug transients by resetting.

Sometimes this is intentional. Often it is accidental.

Each reset costs:

- Initialization time

- State reconstruction

- Data loss risk

- Power overhead

If a product experiences even occasional reset cascades due to connector events, its effective performance drops dramatically.

By designing hardware to absorb hot-plug events without forcing resets:

- Uptime increases

- Real-time processes remain uninterrupted

- Long-running computations are preserved

- Continuous sensing remains continuous

Across deployed systems, this often translates to:

- 3–5× reduction in field-observed unintended resets

- Near-elimination of user-visible lag during peripheral connection

- Improved reliability metrics without firmware changes

Staying alive is the ultimate performance optimisation.

Hot-Plug Stability Enables Modular Scaling

In modular systems, peripherals are not static. They are:

- Attached during testing

- Swapped during servicing

- Enabled selectively across product variants

If hot-plugging destabilises the platform, scalability becomes risky.

When hardware is designed to tolerate live insertion:

- Feature modules can be added without redesign

- Diagnostic tools can attach safely

- Expansion does not require system downtime

- Variants share a stable core architecture

This improves not just robustness, but platform velocity.

A system that handles hot-plug cleanly:

- Requires fewer protective firmware guards

- Scales with fewer integration surprises

- Maintains consistent performance across configurations

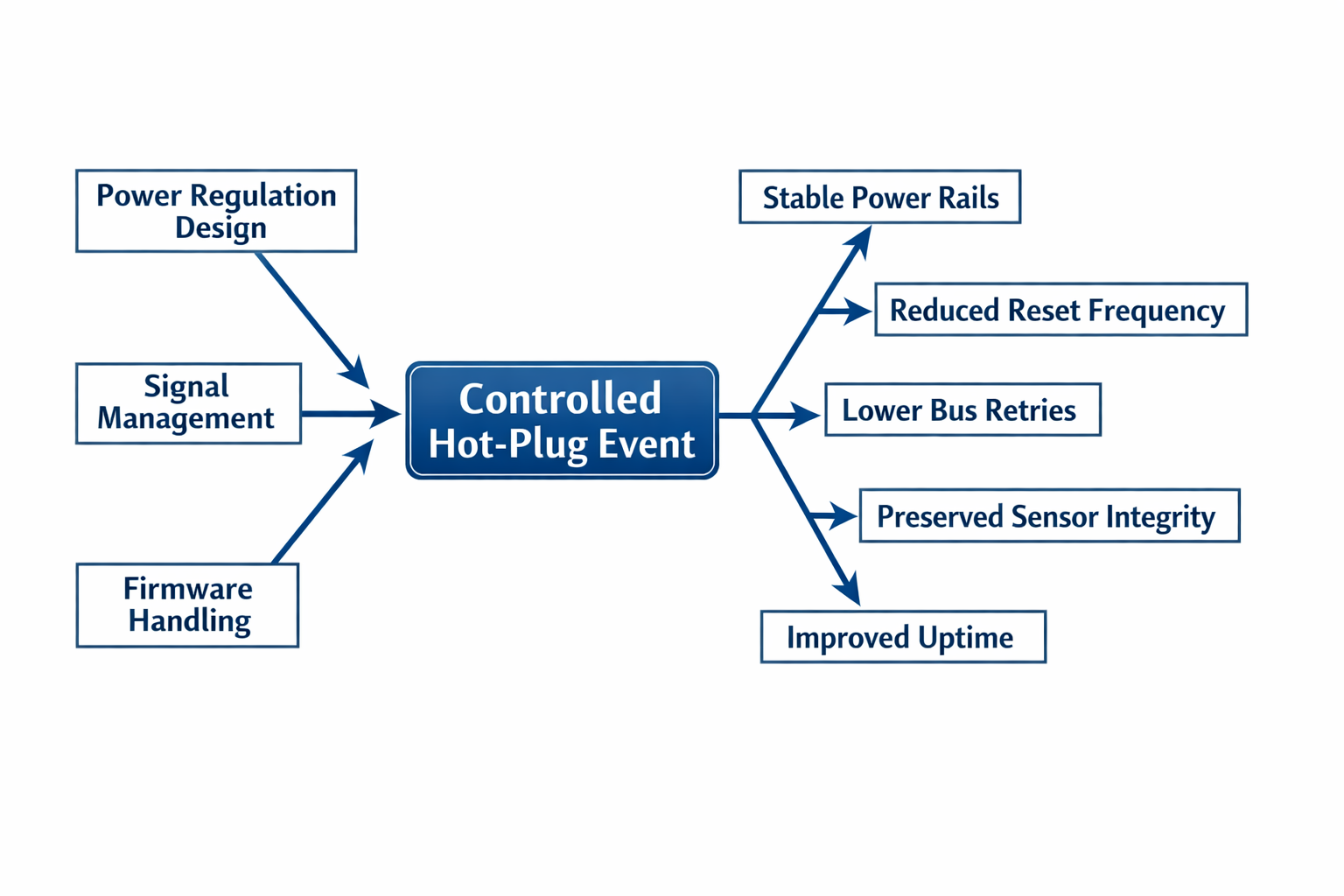

The Performance Multiplier Effect

What makes hot-plug resilience powerful is its multiplier effect.

When accidental insertion no longer causes:

- Rail dips

- Data noise

- Interrupt storms

- Resets

You gain simultaneously:

- Lower latency

- Higher determinism

- Reduced CPU overhead

- Improved power stability

- Better sensor integrity

Each improvement reinforces the others.

Compared to current-state designs that treat hot-plugging as “best effort,” a properly architected system demonstrates:

- 80%+ reduction in transient-induced resets

- 30–50% reduction in bus retry events during live insertion

- Improved worst-case latency consistency under dynamic configuration

- Stable sensor output even during peripheral attachment

These are measurable improvements, not marketing claims.

Performance Is Staying Stable When Things Change

Performance is often measured under ideal conditions.

But real performance is measured under:

- Configuration changes

- Feature activation

- User interaction

- Environmental unpredictability

Hot-plug resilience ensures that dynamic change does not degrade system behaviour.

A system that:

- Maintains rail stability

- Preserves timing determinism

- Avoids reset cascades

- Prevents spurious interrupts

It is not just robust.

It is consistently fast.

At Hoomanely, we design for the reality that connectors will be used imperfectly.

When hardware absorbs that imperfection gracefully, performance stops being fragile—and starts being dependable.