Engineering for Longevity: Thermal and Moisture Management in vBus Products

Introduction: Designing for Real-World Environments

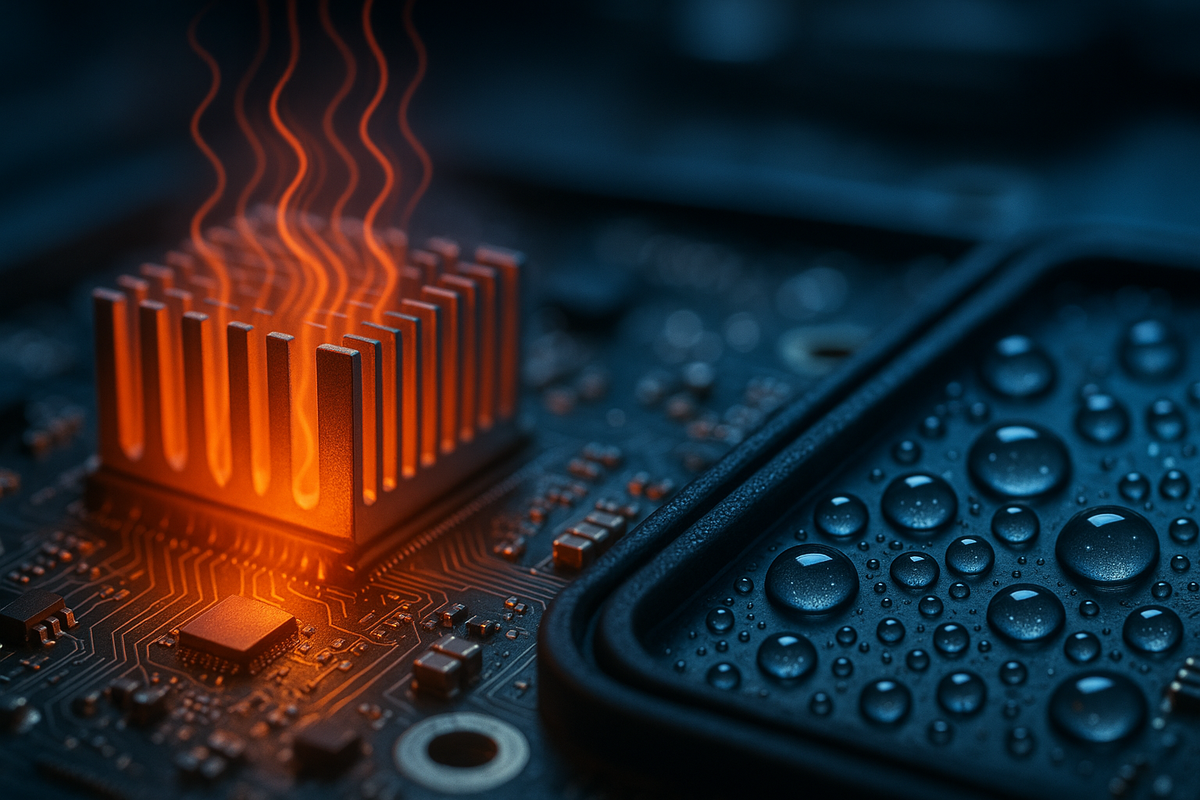

At Hoomanely, our vBus modular architecture delivers sophisticated functionality in compact form factors. This integration density brings a fundamental engineering challenge: managing heat generation from high-performance components while protecting sensitive electronics from environmental moisture. Our approach to thermal and moisture management isn't an afterthought—it's engineered into every module from the initial design phase.

Consumer electronics operate in diverse indoor environments: climate-controlled offices, humid bathrooms, kitchens with steam and temperature swings, and living spaces where conditions fluctuate daily. Our products must maintain performance and reliability across these scenarios, which requires systematic attention to thermal dissipation and moisture protection at both the PCB and enclosure levels.

Today, I want to share the thermal and moisture management strategies that ensure our vBus products deliver consistent, long-term performance in real-world consumer environments.

Thermal Management: Identifying and Addressing Heat Sources

Heat Generation in vBus Modules

Each SoM category in our ecosystem has distinct thermal characteristics driven by the high-power components it contains:

CPU SoMs - The Thermal Hotspot:

The processor is invariably the primary heat source. Modern ARM Cortex-A series processors running at 400MHz to 1.5GHz can dissipate 2-5 watts continuously, with peaks reaching 8-10 watts during intensive computation. At these power levels, junction temperatures quickly approach maximum ratings without proper thermal management.

Our CPU SoMs typically feature:

- Main processor (AM62A7, STM32P series, or similar): 2-5W continuous

- DDR memory: 0.5-1W depending on capacity and speed

- Power management ICs: 0.5-1W (conversion losses in regulators)

- High-speed transceivers (CAN-FD, USB): 0.3-0.5W each

Total power dissipation: 4-8 watts in a module measuring just 50mm × 70mm. This power density demands deliberate thermal design.

Power SoMs - Conversion Efficiency Matters:

Power conversion generates heat proportional to current delivered and conversion efficiency. Our Power SoMs handle system power distribution:

- DC-DC buck converters (5V, 3.3V, 1.8V rails): Each regulator dissipates power based on (Vin - Vout) × Iout × (1 - efficiency)

- High-side power switches (MOSFETs): I²R losses in the on-resistance plus switching losses

- Current sensing circuits: Minimal but measurable power dissipation

A Power SoM delivering 20 watts total output at 90% efficiency dissipates approximately 2 watts as heat. While lower than CPU thermal loads, this heat is concentrated in switching regulators and power MOSFETs—components with thermal limits that must be respected.

Peripheral SoMs - Localized Thermal Concerns:

Most peripheral modules run cooler due to lower-power MCUs (STM32H5, ESP32-C6) typically dissipating 100-500mW. However, specific peripherals introduce localized heating:

- Camera sensor modules: Image sensor and processing can reach 1-2W

- Motor driver circuits: H-bridge MOSFETs dissipate significant heat under load

- High-brightness LED drivers: Power LEDs generate substantial heat

Communication SoMs - RF Power Amplifiers:

Wireless transmission creates heat:

- WiFi radio: 0.5-1W during active transmission

- Bluetooth: 100-200mW (lower power profile)

- LoRa: 100-500mW depending on transmission power

These thermal loads may seem modest individually, but in a compact, enclosed product, every watt matters.

PCB-Level Thermal Design Strategies

Copper Thermal Management

Our primary thermal management tool is copper—the PCB itself becomes a heat spreader and dissipation surface.

Thermal Vias Under Hot Components:

High-power components (processors, power regulators, MOSFETs) are mounted above arrays of thermal vias—plated through-holes filled or plugged with solder that conduct heat from the component side through to internal copper planes and the opposite side of the PCB.

Implementation:

- Via diameter: 0.3mm (12 mil)

- Via spacing: 0.5-1mm grid pattern

- Quantity: 20-40 vias under typical QFN or BGA package

- Thermal conductivity improvement: 40-60% compared to no vias

These via arrays create low thermal resistance paths from junction to ambient, significantly improving heat dissipation.

Copper Pour and Plane Usage:

Where possible, we dedicate copper planes or large pours to thermal management:

CPU SoMs: Ground plane under processor acts as heat spreader, distributing thermal energy across the entire PCB area rather than concentrating it locally.

Power SoMs: Wide copper traces for power distribution serve dual purpose—carrying current with minimal resistance (reducing I²R heating) and spreading heat from regulators across larger area.

Multi-Layer Thermal Design: In 4-layer or 6-layer designs, internal planes adjacent to component layers provide thermal mass and heat spreading, while outer layers radiate heat to ambient air.

Component Placement for Airflow

When natural convection is the primary cooling mechanism (as in most of our consumer products), component placement matters:

Vertical Orientation Consideration: Hot components positioned toward the top of the PCB benefit from natural convection—heated air rises, pulling cooler air up from below.

Spacing Between Heat Sources: We avoid clustering high-power components. Spacing them distributes heat generation across the PCB, preventing localized hot spots that exceed component ratings.

Proximity to Enclosure Walls: Strategic placement near enclosure surfaces with ventilation or thermal contact paths enables heat transfer from PCB to enclosure to ambient.

Thermal Interface Materials

For high-power components, we supplement PCB thermal management with thermal interface materials:

Thermal Pads: Silicone or graphite-based pads placed between component and enclosure transfer heat efficiently. Common on CPU SoMs where processor requires additional heat sinking beyond PCB copper.

Thermal Adhesive: Double-sided thermal adhesive tape mounts heatsinks to components or bonds PCB to metal enclosure sections, creating thermal conduction paths.

Gap Fillers: Conformable thermal gap filler materials accommodate tolerance stack-up between component and heatsink or enclosure, ensuring consistent thermal contact despite manufacturing variation.

Heatsink Integration in Compact Designs

Passive Heatsinking Strategies

Active cooling (fans) introduces noise, consumes power, and adds mechanical complexity—undesirable in consumer products. Our thermal designs emphasize passive cooling:

Surface-Mount Heatsinks: Small aluminum or copper heatsinks mounted directly to high-power components. We use heatsinks on:

- CPU processors (especially quad-core and higher performance variants)

- Power regulators delivering >2A continuously

- Driver MOSFETs in peripheral modules

These heatsinks increase effective surface area by 10-30×, dramatically improving natural convection cooling.

Enclosure as Heatsink: In products with metal enclosures (aluminum or steel), the enclosure itself becomes the primary heatsink. Thermal pads connect high-power PCB components to enclosure inner surfaces, and the entire enclosure radiates heat to ambient.

This approach is particularly effective for CPU SoMs where the processor thermal pad bonds through the PCB (via thermal vias) to a copper area on the bottom side, which then contacts the enclosure through thermal interface material.

Moisture Protection: Defending Against Environmental Humidity

Why Moisture Matters

Consumer electronics encounter moisture from multiple sources:

- Ambient humidity: 30-80% relative humidity typical in homes

- Condensation: Temperature swings (moving device from cold to warm environment) cause condensation on surfaces

- Direct exposure: Products used in bathrooms, kitchens, or near open windows encounter steam, splashes, or rain

Moisture on PCBs causes multiple failure mechanisms:

Corrosion: Water enables electrochemical reactions that corrode copper traces, component leads, and solder joints. This manifests as increased resistance, intermittent connections, or complete open circuits.

Leakage Current: Moisture on PCB surfaces creates conductive paths between adjacent traces or pads, causing leakage current that affects sensitive analog circuits and increases power consumption.

Sensor Drift: Many sensors—temperature, humidity, gas sensors, analog interfaces—are sensitive to moisture on their sensing elements or associated circuitry, causing measurement drift or inaccuracy.

Component Damage: Moisture ingress into IC packages or under components leads to delamination, corrosion of bond wires, and long-term reliability degradation.

PCB-Level Moisture Protection

PCB Material Selection:

Standard FR4 PCB substrate absorbs moisture over time. For enhanced moisture resistance, we specify:

- High Tg FR4: Higher glass transition temperature correlates with lower moisture absorption

- Polyimide substrate: Used in extreme cases, offers superior moisture resistance but at higher cost

Enclosure Sealing Strategy

The enclosure is the primary moisture barrier. Our designs ensure robust sealing:

Gasket Sealing:

Critical seam lines—where enclosure halves mate—include gaskets:

Material: Silicone or EPDM rubber gaskets, either discrete gasket components or overmolded gaskets integrated into plastic enclosures.

Compression: Gasket design ensures proper compression when enclosure is assembled, creating continuous seal around entire perimeter.

IP Rating Target: For consumer indoor products, we typically target IP54 (dust protected, splash resistant) or IP55 (dust protected, water jet resistant). This protects against accidental splashes and high humidity without requiring submersion protection.

Connector Sealing:

External connectors (USB, barrel jack, sensor ports) create potential moisture ingress paths:

Gasketed Connectors: We specify connectors with integral gaskets that seal against the enclosure cutout.

Sensitive Component Protection

Certain components require additional protection:

Analog Sensor Circuits:

High-impedance analog inputs are particularly susceptible to leakage current from moisture:

Protection Strategy:

- Guard rings on PCB (grounded copper traces surrounding high-impedance nodes)

- Conformal coating with extra thickness in sensitive areas

- Component selection favoring moisture-resistant packages (ceramic vs. plastic)

Environmental Sensors:

Sensors must access the environment but remain protected:

Selective Exposure: Enclosure design includes protected chambers where sensors mount—open to ambient air through filtered vents but shielded from direct water contact.

Sensor Selection: We choose sensors with integrated moisture protection (stainless steel housings, hydrophobic filters, IP-rated packages).

Moisture-Sensitive Components Storage:

During manufacturing, moisture-sensitive components (MSL-rated ICs) require proper handling:

- Storage in moisture barrier bags with desiccant

- Baking before reflow if exposure limits exceeded

- Tracking of floor life (time since removed from dry storage)

This prevents moisture absorption during storage that would cause popcorning (internal moisture vaporization causing package delamination) during reflow soldering.

Testing and Validation

Thermal Testing Protocol

Every new product undergoes thermal validation:

Thermal Soak Test: Operating at maximum power dissipation in enclosed environment at 40°C ambient for 24-48 hours. Temperature monitoring confirms all components remain within rated limits.

Thermal Cycling: Repeated cycles between temperature extremes (0°C to 50°C typical for consumer products) verify thermal expansion/contraction doesn't cause solder joint fatigue or mechanical stress.

Thermal Imaging: Infrared camera inspection during operation identifies hot spots and validates thermal simulation predictions.

Design Guidelines Across vBus Modules

CPU SoM Thermal Guidelines

- Processor requires thermal via array (minimum 30 vias)

- Heatsink or thermal pad to enclosure mandatory for processors >2W

- Thermal simulation required for all CPU SoM variants

Power SoM Thermal Guidelines

- High-side MOSFETs require thermal vias and copper pour heat spreading

- Switching regulators positioned for airflow access

- Current sensing resistors rated for continuous power dissipation

Peripheral SoM Moisture Guidelines

- Sensor interfaces receive extra conformal coating thickness

- Analog circuits include PCB guard rings

- Environmental sensors use IP-rated packages or protective enclosures

- Connector interfaces sealed or protected when exposed

Communication SoM Combined Management

- RF power amplifiers require thermal management (copper pour, thermal vias)

- Antenna connections sealed or gasketed

Conclusion: Reliability Through Environmental Design

Thermal and moisture management aren't afterthoughts in our vBus product development—they're integral design considerations from day one. By systematically addressing heat dissipation through PCB copper design, thermal interface materials, and passive heatsinking, we ensure components operate within ratings for long-term reliability. By protecting against moisture through enclosure sealing, and strategic component selection, we prevent corrosion and maintain sensor accuracy over the product lifecycle.

These environmental design strategies enable our vBus modules to deliver consistent performance across the diverse conditions of real-world consumer use—from the humidity of a bathroom to the dry heat of a winter living room, from the temperature swings of a kitchen to the climate-controlled stability of an office. Engineering for longevity means engineering for the environment, and that's exactly what we've done.