Engineering Order at Scale: Device Class Governance in the vBus Ecosystem

Introduction: Structure Enables Velocity

At Hoomanely, our vBus architecture isn't just about electrical interfaces and modular hardware—it's a complete design philosophy that extends into every aspect of how we organize, manage, and deliver our products. As our ecosystem has grown to encompass dozens of SoM variants, carrier boards, and product configurations, we've discovered a fundamental truth: disciplined organization is the foundation of rapid innovation.

We call this approach Device Class Governance—a comprehensive framework for managing the entire lifecycle of hardware designs from concept through production. It encompasses three critical pillars: rigorous folder discipline, production file standardization, and systematic review checklists. Together, these create an environment where designs are instantly recognizable, manufacturing handoffs are seamless, and quality is built into the process rather than inspected in afterward.

The result? Engineering teams that can navigate any design in minutes, manufacturing that receives production-ready files on the first attempt, and a scalable system that grows elegantly as our product portfolio expands. Today, I want to share how we've engineered systematic excellence into our hardware development workflow.

Folder Discipline: The Foundation of Organized Design

The Power of Systematic Naming

Every PCB design at Hoomanely begins with a properly structured project folder, and that folder's name tells a complete story. We've developed a naming convention that encodes essential information directly into the folder name itself, making every project instantly identifiable and categorizable.

Our Standard Folder Nomenclature:

[PRODUCT_LINE]-[MODULE_TYPE]-[VARIANT]-[VERSION]

Real-World Examples:

VBUS-CPU-STM32H7-V2.1

└─ Product Line: vBus ecosystem

└─ Module Type: CPU SoM

└─ Variant: STM32H7-based processor

└─ Version: Hardware revision 2.1

VBUS-PERIPH-IMU-V1.3

└─ Product Line: vBus ecosystem

└─ Module Type: Peripheral SoM

└─ Variant: IMU (Inertial Measurement Unit)

└─ Version: Hardware revision 1.3

VBUS-COMM-LORA-V3.0

└─ Product Line: vBus ecosystem

└─ Module Type: Communication SoM

└─ Variant: LoRa wireless

└─ Version: Hardware revision 3.0

VBUS-PWR-5A-V1.0

└─ Product Line: vBus ecosystem

└─ Module Type: Power SoM

└─ Variant: 5-Ampere capacity

└─ Version: Hardware revision 1.0

This structured approach provides immediate clarity. When an engineer sees VBUS-PERIPH-ENV-V2.2, they instantly know: it's a vBus Peripheral SoM containing environmental sensors, at hardware revision 2.2. No guessing, no cross-referencing documentation—the information is self-evident.

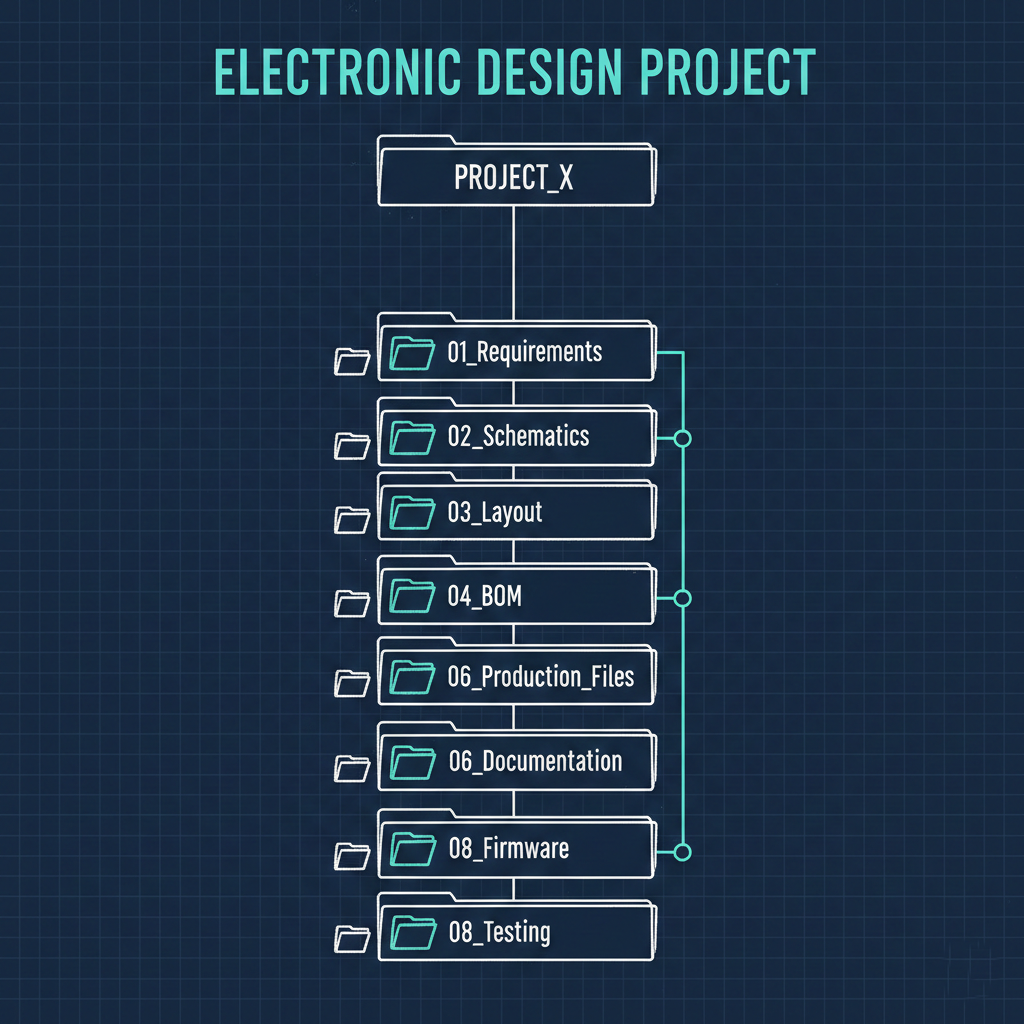

Hierarchical Folder Structure

Inside each project folder, we maintain a rigorous internal structure that mirrors our development workflow:

VBUS-CPU-STM32H7-V2.1/

│

├── 01_Requirements/

│ ├── Product_Requirements_Document.pdf

│ ├── Technical_Specifications.xlsx

│ └── Interface_Definition.md

│

├── 02_Schematics/

│ ├── VBUS-CPU-STM32H7-V2.1_Schematic.pdf

│ ├── Source_Files/

│ │ ├── VBUS-CPU-STM32H7-V2.1.DSN (KiCad/Altium project)

│ │ └── Libraries/

│ └── Design_Notes.md

│

├── 03_Layout/

│ ├── VBUS-CPU-STM32H7-V2.1_Layout.pdf

│ ├── Source_Files/

│ │ └── VBUS-CPU-STM32H7-V2.1.brd

│ └── Stackup_Definition.pdf

│

├── 04_BOM/

│ ├── VBUS-CPU-STM32H7-V2.1_BOM.xlsx

│ ├── BOM_Secondary_Sources.xlsx

│ └── Component_Lifecycle_Tracking.xlsx

│

├── 05_Production_Files/

│ ├── Gerbers/

│ ├── Assembly_Drawings/

│ ├── Pick_and_Place/

│ └── Test_Specifications/

│

├── 06_Documentation/

│ ├── Design_Review_Minutes/

│ ├── Validation_Reports/

│ └── User_Guide/

│

├── 07_Firmware/

│ ├── Bootloader/

│ ├── Production_Firmware/

│ └── Test_Firmware/

│

└── 08_Testing/

├── Test_Procedures/

├── Test_Results/

└── Qualification_Reports/

Benefits of Disciplined Organization

This systematic approach delivers tangible advantages:

Instant Navigation: Any engineer can locate the schematic, BOM, or production files for any design within seconds. No searching, no asking around—the structure is universal.

Version Control Integration: Folder names include version numbers, making revision tracking explicit. When files are committed to version control systems (Git, SVN), the folder structure creates natural organizational hierarchy.

Cross-Project Consistency: Design reuse becomes trivial. Need to reference how we handled power distribution in a previous CPU SoM? The folder structure is identical, so you know exactly where to look.

Automated Tooling: Scripts and automation tools can reliably operate on our design files because the structure is predictable. Automated BOM extraction, gerber validation, documentation generation—all simplified by consistent organization.

Manufacturing Handoff: When production needs files, there's zero ambiguity. Everything manufacturing needs lives in 05_Production_Files/, clearly labeled and organized.

Knowledge Preservation: Years later, when supporting legacy products, engineers can quickly understand the complete design history because documentation lives in predictable locations.

Production File Expectations: Manufacturing-Ready from Day One

Unified Naming Convention

Production files inherit the same naming convention as their parent folder, creating an unbreakable link between design and manufacturing artifacts. Every file that leaves engineering carries its identity explicitly.

Gerber Files:

VBUS-CPU-STM32H7-V2.1_Gerbers.zip

├── VBUS-CPU-STM32H7-V2.1_Top_Copper.gbr

├── VBUS-CPU-STM32H7-V2.1_Bottom_Copper.gbr

├── VBUS-CPU-STM32H7-V2.1_Top_Silkscreen.gbr

├── VBUS-CPU-STM32H7-V2.1_Top_Soldermask.gbr

└── VBUS-CPU-STM32H7-V2.1_Drill.drl

Assembly Files:

VBUS-CPU-STM32H7-V2.1_Assembly_Drawing_Top.pdf

VBUS-CPU-STM32H7-V2.1_Assembly_Drawing_Bottom.pdf

VBUS-CPU-STM32H7-V2.1_Pick_and_Place.csv

VBUS-CPU-STM32H7-V2.1_BOM_Manufacturing.xlsx

Test Specifications:

VBUS-CPU-STM32H7-V2.1_Test_Procedure.pdf

VBUS-CPU-STM32H7-V2.1_Test_Points_Map.pdf

VBUS-CPU-STM32H7-V2.1_Programming_Instructions.pdf

This naming discipline eliminates one of manufacturing's most common sources of confusion: "Which files belong together?" When every file shares the same base identifier, assembly of the correct documentation package becomes foolproof.

Complete Production Package Standard

We've defined exactly what constitutes a "complete" production file package. Every release includes:

1. Fabrication Files:

- Complete gerber set (all copper layers, silkscreen, soldermask, paste)

- NC drill files with tool definitions

- Board outline and dimensional drawing

- Stackup specification with impedance requirements

- Material specifications and finish requirements

2. Assembly Files:

- Top and bottom assembly drawings with component reference designators

- Pick-and-place file (CSV format) with X/Y coordinates and rotation

- Manufacturing BOM with exact manufacturer part numbers

- Component placement notes for special-handling components

- Paste stencil specifications if non-standard

3. Quality Control Files:

- Test point location map

- Electrical test specifications (netlist, boundary scan)

- Visual inspection criteria

- First-article inspection requirements

- Acceptance criteria and tolerances

4. Documentation:

- Design intent notes (critical traces, thermal considerations)

- Known issues or errata (if any)

- Rework procedures (if applicable)

- Revision history and change summary

- Contact information for engineering support

The Manufacturing Handoff Checklist

Before any design is released to manufacturing, it passes through our standardized handoff checklist:

✓ Folder name matches version and variant ✓ All production files use consistent naming convention ✓ Gerber files validated with third-party viewer ✓ Pick-and-place coordinates verified against assembly drawing ✓ BOM matches schematic component count ✓ All components have valid manufacturer part numbers ✓ Second-source options documented for critical components ✓ Test specifications reference correct test points ✓ Programming instructions validated on prototype hardware ✓ Design review sign-off documentation included

This checklist ensures manufacturing receives complete, accurate, production-ready files on the first submission—no back-and-forth, no missing documents, no ambiguity.

Review Checklists: Engineering Excellence Through Systematic Validation

The Multi-Tiered Review Process

At Hoomanely, we've developed comprehensive design review checklists that systematically validate every aspect of a design before it progresses to the next stage. These aren't bureaucratic hurdles—they're structured frameworks that help engineers deliver their best work.

Schematic Review Checklist:

Electrical Integrity:

✓ All power nets properly annotated with voltage and current budget

✓ All signal nets follow vBus naming conventions

✓ Decoupling capacitors placed at every power pin

✓ Pull-up/pull-down resistors on critical signals

✓ ESD protection on external interfaces

✓ No unconnected pins on active components

Interface Compliance:

✓ vBus connector pinout matches standard

✓ Communication interfaces (I2C, SPI, CAN) properly terminated

✓ Differential pairs matched for impedance

✓ Clock signals have series termination resistors

✓ Debug interfaces (JTAG/SWD) accessible and properly configured

Power Distribution:

✓ Power sequencing requirements documented

✓ Current budget analysis completed for all rails

✓ Voltage regulation margins verified

✓ Thermal dissipation calculated for regulators

✓ Ground domains properly isolated where required

Component Selection:

✓ All components have second-source alternatives documented

✓ Component lifecycle status verified (not end-of-life)

✓ Operating temperature ranges meet requirements

✓ Package availability confirmed for volume production

PCB Layout Review Checklist:

Mechanical Compliance:

✓ Board dimensions match mechanical drawing

✓ Mounting holes positioned correctly with proper clearance

✓ Connector placement matches vBus standard locations

✓ Component height restrictions observed

✓ Keep-out zones respected (mechanical, thermal, RF)

Signal Integrity:

✓ High-speed traces impedance-controlled

✓ Differential pairs routed with matched length

✓ Critical signals avoid crossing split planes

✓ Clock traces follow best practices (short, direct, isolated)

✓ Return paths verified for all high-speed signals

Power Integrity:

✓ Power plane copper area adequate for current requirements

✓ Via stitching placed at plane boundaries

✓ Decoupling capacitors placed close to power pins

✓ Thermal vias under power components

✓ Current density verified for all traces and planes

Manufacturing Considerations:

✓ Trace widths meet PCB manufacturer minimums

✓ Clearances satisfy fabrication rules

✓ Via sizes within fabrication capabilities

✓ Component footprints match manufacturer drawings

✓ Silkscreen legible and properly placed

✓ Fiducials placed for automated assembly

BOM and Documentation Review:

✓ BOM component count matches schematic

✓ All components have manufacturer part numbers

✓ Second-source alternatives documented

✓ Lifecycle tracking data current

✓ Cost analysis completed

✓ Lead time assessment documented

✓ Assembly notes complete and accurate

✓ Test procedures reference correct revision

The Review Culture

Our checklists aren't just documents—they're living tools that engineers actively use and continuously refine. Key aspects of our review culture:

Peer Review Mandatory: No design progresses without at least two reviewers beyond the original designer. Fresh eyes catch what familiarity misses.

Checklist as Framework: Rather than constraining creativity, checklists free engineers to focus on innovation by handling routine verification systematically.

Continuous Improvement: When a checklist item repeatedly catches issues, we enhance our templates and training to prevent the issue upstream. When checklists miss something, we add the new check immediately.

Cross-Functional Participation: Firmware engineers review schematics for firmware compatibility. Manufacturing engineers review layouts for assembly considerations. Quality engineers validate test specifications. Multiple perspectives ensure comprehensive validation.

Documented Sign-Off: Every reviewer signs off digitally with timestamp and comments. This creates accountability and a clear audit trail for quality purposes.

The Efficiency Multiplier

Our systematic review process delivers measurable results:

- First-Pass PCB Success: 95%+ of designs work correctly on first silicon

- Manufacturing Queries: Reduced by 80% due to complete, clear documentation

- Time to Production: 30% faster from design freeze to manufacturing release

- Design Iteration: Fewer ECOs (Engineering Change Orders) during development

- Quality Metrics: Field failure rates significantly below industry averages

These improvements aren't accidental—they're the direct result of rigorous, systematic validation at every stage.

Integration: How Governance Enables vBus Excellence

Device Class Governance isn't separate from vBus architecture—it's the organizational framework that makes vBus scalable and sustainable. Consider how these elements interlock:

Folder Discipline + Modularity: Each SoM type has its own design folder, but all follow identical internal structure. This makes SoM-to-SoM comparison trivial and design reuse effortless.

Production Files + Standardization: Because every SoM uses standard vBus connectors, production files share common elements. Manufacturing learns the pattern once and applies it everywhere.

Review Checklists + Quality: vBus-specific validation items (connector pinout verification, interface compliance) are built into checklists, ensuring every design maintains ecosystem compatibility.

Naming Convention + Traceability: When a field issue arises, the folder name, production file names, and version control history create an unbroken chain from symptom back to exact design revision and BOM configuration.

Conclusion: Structure as a Competitive Advantage

Device Class Governance might seem like administrative overhead, but it's actually a force multiplier that accelerates everything we do. When folders follow predictable structure, when production files carry complete information, when reviews systematically validate every detail—engineering teams can move fast with confidence.

At Hoomanely, we've learned that discipline and velocity aren't opposites—they're complements. The same governance framework that ensures quality also enables speed. The same review checklists that catch errors also preserve institutional knowledge. The same folder structure that organizes current designs also makes legacy products maintainable.

As our vBus ecosystem continues to grow, Device Class Governance scales effortlessly with it. New SoM types fit naturally into existing structures. New engineers adopt proven patterns immediately. New manufacturing partners receive clear, complete information from day one.

This is engineering excellence as a system—not heroic individual effort, but systematic processes that elevate everyone's work. And that's precisely the kind of scalable foundation that enables ambitious innovation.