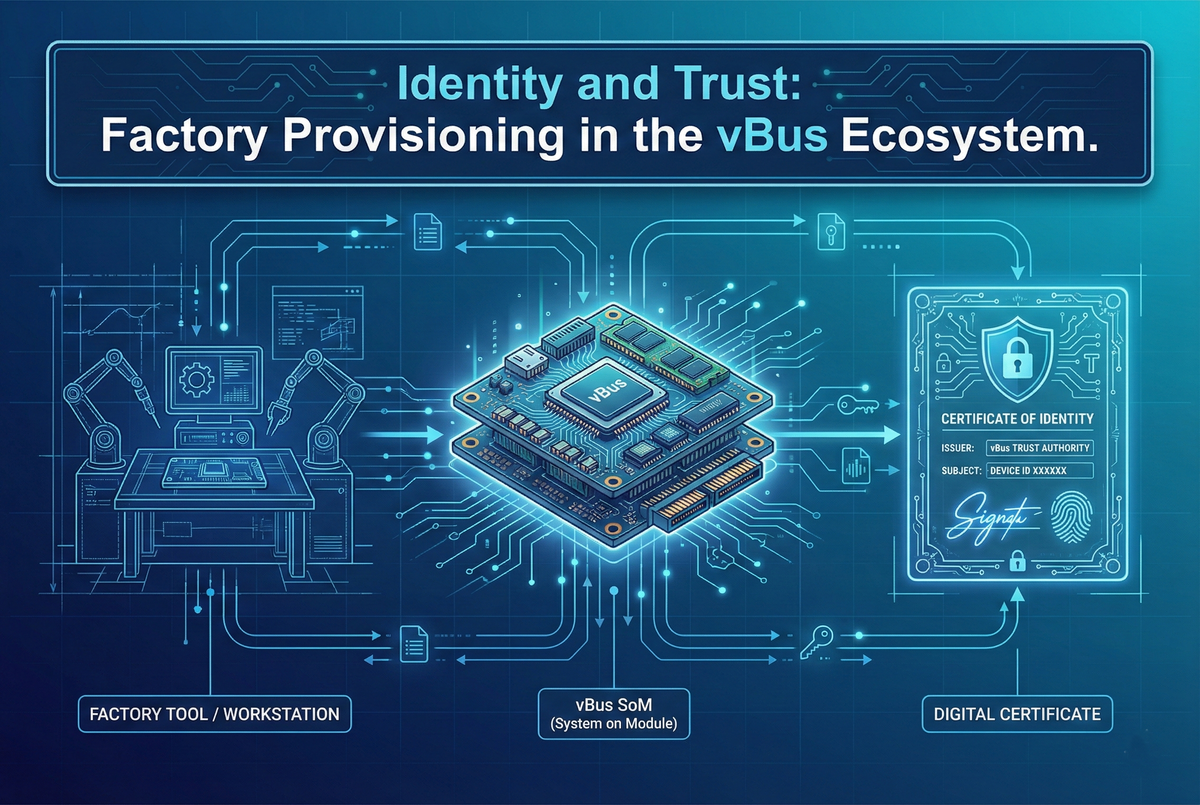

Identity and Trust: Factory Provisioning in the vBus Ecosystem

Introduction: Building Trust from First Power-On

Every Hoomanely product that leaves our manufacturing facility carries a unique digital identity—cryptographic keys, identification codes, calibration data, and quality certification that define it as an authentic, validated device ready for deployment. This identity isn't added as an afterthought; it's engineered into our factory provisioning process, a systematic workflow that transforms blank PCBs into trusted, traceable products.

Factory provisioning is where hardware meets security, where manufacturing meets traceability, and where quality assurance meets product lifecycle management. For our vBus modular architecture, we've developed a standardized provisioning framework that scales across CPU SoMs, Power SoMs, Peripheral SoMs, and Communication SoMs—ensuring consistent identity establishment, secure key injection, and comprehensive documentation regardless of module type.

Today, I want to share how we've engineered factory provisioning as a core competency, enabling secure products, complete traceability, and manufacturing excellence across our entire ecosystem.

The Provisioning Architecture: What Gets Programmed

Factory provisioning encompasses multiple data categories, each serving distinct purposes in the product lifecycle:

Unique Device Identifiers

Every module receives a globally unique identifier that distinguishes it from every other module we've ever manufactured:

Module Serial Number: Human-readable alphanumeric code following standardized format:

Format: [PRODUCT_CODE]-[MODULE_TYPE]-[YEAR][MONTH]-[SEQUENCE]

Example: VBUS-CPU-2412-003847

- PRODUCT_CODE: vBus ecosystem identifier

- MODULE_TYPE: CPU, PWR, PERIPH, COMM

- YEAR/MONTH: Manufacturing date encoding

- SEQUENCE: Unique sequential number within that month

This serial number appears physically (silkscreen, laser marking, or label) and digitally (stored in module EEPROM or flash memory).

Hardware UUID: 128-bit unique identifier generated from:

- Processor-integrated unique ID (most modern MCUs include factory-programmed unique IDs)

- MAC address (for communication modules with network interfaces)

- Cryptographically secure random number (for modules without built-in UIDs)

Manufacturing Batch Code: Links module to specific production run, enabling correlation with component lots, process parameters, and quality data.

Cryptographic Keys and Certificates

Security-critical products require cryptographic identity:

Device Private Keys: Unique asymmetric key pair (typically ECDSA P-256 or RSA-2048) generated during provisioning:

- Private key: Stored securely in module (secure element, encrypted flash, or one-time programmable memory)

- Public key: Extracted and registered in backend system for device authentication

Certificate Chain: For products requiring TLS or mutual authentication:

- Device certificate signed by manufacturing intermediate CA

- Intermediate CA certificate signed by root CA

- Complete chain stored on device for presentation during authentication

Pre-Shared Keys (PSK): For symmetric authentication schemes, unique PSK per device stored both on module and in backend provisioning database.

Encryption Keys: For products with encrypted storage or communication:

- Symmetric keys (AES-256) for data-at-rest encryption

- Key encryption keys (KEKs) protecting other keys in hierarchy

Calibration Data

Sensor and analog modules require calibration for accurate measurements:

Sensor Calibration Coefficients: Temperature sensors, pressure sensors, IMUs, and analog front-ends receive calibration data specific to their individual components:

- Offset corrections

- Gain adjustments

- Linearity compensation coefficients

- Temperature drift compensation parameters

Voltage Reference Calibration: Analog modules measuring voltage, current, or other electrical parameters store reference calibration measured during production test.

RF Calibration: Communication modules with RF transceivers store frequency offset, TX power calibration, and RSSI correction factors.

Firmware and Configuration

Bootloader: Secure bootloader programmed first, establishing root of trust for subsequent firmware updates.

Application Firmware: Latest validated firmware version flashed during provisioning.

Default Configuration: Product-specific configuration parameters:

- Hardware variant identification

- Feature enable/disable flags

- Default operational parameters

- Regional settings (frequency bands, regulatory parameters)

Quality Control Documentation

Test Results: Comprehensive functional test data embedded in module memory:

- Test sequence execution log

- Pass/fail status per test

- Measured parameters (voltages, currents, frequencies)

- Test station ID and operator ID

- Timestamp of testing

Component Traceability: Critical component identifiers linking module to:

- Processor lot code

- Memory device lot code

- Sensor device lot codes

- PCB fabrication lot

- Assembly house and date

This embedded traceability enables field failure analysis and quality correlation without external database lookups.

The Provisioning Workflow: From Blank to Trusted

Stage 1: Pre-Provisioning Preparation

Component Programming: Some components arrive pre-programmed:

- Secure elements or TPMs with factory-installed keys

- Memory devices with unique identifiers

- Wireless modules with MAC addresses and certifications

Database Registration: Manufacturing execution system (MES) assigns serial numbers and generates provisioning data packages for each unit entering production.

Stage 2: Initial Programming

Bootloader Flash: First code programmed onto blank module via JTAG/SWD interface:

- Minimal bootloader establishing secure boot capability

- Locked to prevent unauthorized modification

- Public key hash embedded (for firmware signature verification)

Hardware UID Extraction: Bootloader reads processor unique ID and reports to provisioning station, linking physical hardware to database record.

Stage 3: Key Generation and Injection

On-Device Key Generation: For maximum security, private keys generated on-device using hardware random number generator (HWRNG):

- Provisioning station sends "generate keys" command via debug UART

- Module HWRNG generates cryptographically secure random seed

- Key pair generated on-device (private key never leaves module)

- Public key returned to provisioning station

- Station generates signed certificate using public key

- Certificate injected back into module secure storage

Secure Element Programming: Modules with dedicated secure elements (ATECC608, SE050, TPM) receive keys via secure channel:

- Authenticated session established

- Keys injected using secure element vendor tools

- Permanent write-lock ensures keys cannot be extracted or modified

Key Escrow: For enterprise products requiring key recovery, encrypted private key backup stored in HSM-protected key escrow system with strict access controls.

Stage 4: Calibration Execution

Automated Calibration Stations: Modules requiring calibration move to dedicated calibration fixtures:

Environmental Sensors: Placed in calibrated reference environment:

- Temperature chamber at known temperatures (0°C, 25°C, 50°C)

- Humidity chamber at known RH levels

- Module readings compared to reference, coefficients calculated and written

Analog Inputs: Precision voltage/current sources applied to inputs:

- Multiple known values across measurement range

- Linear regression calculates gain and offset corrections

- Coefficients stored in non-volatile memory

IMU Calibration: Accelerometer and gyroscope placed on precision rotation fixture:

- Zero-g calibration (offset extraction)

- Rotation through known angles (gain calibration)

- Multi-axis calibration ensuring measurement accuracy

RF Calibration: Communication modules connected to vector network analyzer:

- Frequency offset measured and corrected

- TX power calibrated across channels

- RX sensitivity verified and documented

Calibration data written to dedicated EEPROM section or flash memory region protected from accidental erasure.

Stage 5: Firmware Loading

Application Firmware Flash: Production firmware version loaded via:

- Bootloader UART interface

- USB DFU (Device Firmware Update) protocol

- JTAG/SWD for initial programming

Firmware Signing: All production firmware digitally signed:

- Hash of firmware calculated

- Hash signed with manufacturer private key

- Signature appended to firmware image

- Bootloader verifies signature before execution

Version Locking: First firmware version recorded in tamper-protected storage, establishing baseline for anti-rollback protection.

Stage 6: Functional Testing

Comprehensive Test Suite: Every provisioned module undergoes automated functional testing:

Power Distribution Test: Verify all voltage rails within specification under no-load and rated load.

Communication Interface Test: Verify UART, I2C, SPI, CAN, and USB (as applicable) functionality with loopback or external device communication.

Sensor Validation: For Peripheral SoMs, verify sensor readings within expected ranges and calibration accuracy.

Wireless Performance: For Communication SoMs, verify RF output power, receiver sensitivity, and protocol compliance.

vBus Enumeration Test: Verify module correctly identifies itself over vBus interface and responds to standard commands.

Test results logged both to provisioning station database and to module internal storage for field reference.

Stage 7: Quality Documentation

QC Data Package Creation: For each module, comprehensive documentation generated:

Test Report PDF: Human-readable test report including:

- Serial number and hardware version

- Test sequence with pass/fail per step

- Measured values and specifications

- Calibration coefficients applied

- Test station ID and timestamp

- Digital signature for authenticity

Traceability Record: Component genealogy linking:

- PCB fabrication lot and date

- Assembly house and date

- All critical component lot codes

- Firmware version programmed

- Calibration data source

Certificate of Conformity: For regulated products, formal certificate documenting compliance with applicable standards and test results proving conformance.

Label Generation: Physical label printed with:

- QR code encoding serial number

- Human-readable serial number

- Manufacturing date

- Product variant identifier

- Regulatory markings (CE, FCC, RoHS as applicable)

Stage 8: Final Lock-Down

Memory Protection: Security-critical regions write-protected:

- Bootloader region locked via hardware write-protection

- Key storage areas permanently locked

- Calibration data protected from accidental overwrite

- OTP (one-time programmable) fuses blown to disable debug interfaces in production mode

Final Verification: One last automated check confirms:

- Module boots correctly

- Security features active (debug disabled, secure boot functional)

- All protection mechanisms engaged

- No test/debug functionality remaining accessible

Provisioning Infrastructure: The Technical Stack

Hardware Systems

Programming Stations: Dedicated workstations with:

- Multi-channel JTAG/SWD programmers (programming multiple modules simultaneously)

- USB hubs for UART-based provisioning

- Secure element programming adapters

- Network connectivity to MES and key management systems

Calibration Equipment:

- Temperature chambers (precision ±0.1°C)

- Humidity chambers (precision ±2% RH)

- Precision voltage/current sources (5+ digit resolution)

- Multi-axis rotation fixtures for IMU calibration

- RF test equipment (vector network analyzers, spectrum analyzers)

Test Fixtures: Custom designed per module type:

- Pogo-pin contact fixtures for JTAG/UART/power connection

- Automated clamping mechanisms for repeatable contact

- Integration with pneumatic or servo systems for high-throughput operation

Software Systems

Manufacturing Execution System (MES): Central system managing:

- Serial number allocation

- Work order tracking

- Provisioning data generation

- Test result collection and analysis

- Yield monitoring and reporting

Key Management System (KMS): Secure HSM-backed system for:

- Certificate authority operations (signing device certificates)

- Key generation coordination

- Key escrow (when required)

- Audit logging of all key operations

Provisioning Software: Station-level software controlling:

- Programming tool invocation

- Test sequence execution

- Data upload to MES

- Label printing

- Pass/fail adjudication

Calibration Database: Centralized storage of:

- Calibration coefficients per serial number

- Reference equipment calibration certificates

- Calibration station validation records

- Traceability of calibration to national standards

vBus Standardization: Consistent Provisioning Across Modules

Module-Specific Provisioning Profiles

While the workflow remains consistent, each module type has tailored provisioning requirements:

CPU SoM Provisioning:

- Bootloader with secure boot capability

- Device private key and certificate chain

- MAC address (for Ethernet-capable variants)

- Hardware UID extraction and registration

- Full functional test including DDR memory, flash, and peripherals

Power SoM Provisioning:

- Voltage reference calibration per rail

- Current sense calibration per rail

- Thermal sensor calibration

- Output voltage accuracy verification across load range

- Overcurrent protection threshold verification

Peripheral SoM Provisioning:

- Sensor-specific calibration (temperature, humidity, pressure, IMU, etc.)

- Analog input calibration if applicable

- Sensor functional validation

- Communication interface testing with CPU SoM

Communication SoM Provisioning:

- MAC address (WiFi, Bluetooth, Ethernet as applicable)

- RF calibration (frequency offset, TX power, RSSI)

- Regulatory certification data embedded (FCC ID, IC, CE)

- Wireless protocol compliance testing

- Antenna performance validation

Security Considerations

Key Protection

Hardware Security Modules (HSM): All root keys and certificate authority private keys stored in FIPS 140-2 Level 3 certified HSMs, never exposed to general-purpose computing systems.

Secure Manufacturing Network: Provisioning stations operate on isolated network segment:

- No internet connectivity (air-gapped or firewalled)

- Access restricted to authorized personnel

- All access logged and audited

- Encrypted communication between stations and key management systems

Key Lifecycle Management: Comprehensive policies govern:

- Key generation (on-device where possible, HSM-generated otherwise)

- Key storage (secure elements, encrypted flash, OTP memory)

- Key usage (authentication, encryption, signing)

- Key rotation (periodic update of symmetric keys)

- Key revocation (certificate revocation lists for compromised devices)

Provisioning Audit Trail

Complete Logging: Every provisioning operation logged:

- What was programmed (serial number, keys, firmware, calibration)

- When it occurred (timestamp with millisecond precision)

- Where it occurred (station ID, operator ID)

- Result (success, failure, specific error codes)

Immutable Records: Audit logs stored in append-only database with cryptographic integrity protection, enabling investigation of any provisioning-related field issues.

Quality Assurance Integration

Statistical Process Control

Provisioning data feeds real-time quality dashboards:

First-Pass Yield: Percentage of modules passing functional test on first attempt—tracks manufacturing quality and identifies systematic issues.

Calibration Drift: Tracking calibration coefficients over time reveals component variation trends or fixture drift requiring recalibration.

Test Time Monitoring: Sudden increases in test duration indicate station performance degradation or test software issues.

Failure Pareto: Which tests fail most frequently? Identifies design weaknesses or manufacturing process issues.

Traceability for Root Cause Analysis

When field failures occur, provisioning data enables rapid investigation:

Component Correlation: Is the failure correlated with specific component lots? Traceability data reveals supplier quality issues.

Manufacturing Date Correlation: Failures clustered by date suggest process excursions during that period.

Test Result Analysis: Did the failed unit show marginal behavior during provisioning testing? Tightening test limits may catch future issues.

Calibration Quality: Are failures correlated with calibration accuracy? Indicates need for improved calibration processes.

Conclusion: Foundation of Product Trust

Factory provisioning is where our vBus products gain their identity, establish their security credentials, and prove their functionality. This systematic, standardized process ensures that every module—whether CPU, Power, Peripheral, or Communication—carries the digital identity, cryptographic keys, calibration accuracy, and quality documentation that define it as a genuine, validated Hoomanely product.

The investment in comprehensive provisioning infrastructure pays dividends throughout the product lifecycle: secure device authentication protects against counterfeiting, complete traceability enables rapid root cause analysis, embedded calibration data ensures measurement accuracy, and comprehensive test documentation proves quality at every stage.

As our vBus ecosystem grows, the provisioning framework scales with it—new module types integrate seamlessly into established workflows, consistent data structures enable unified tools, and standardized security practices ensure trust across the entire product portfolio. Factory provisioning isn't just a manufacturing step; it's the foundation of product trust, quality, and security that defines the Hoomanely brand.