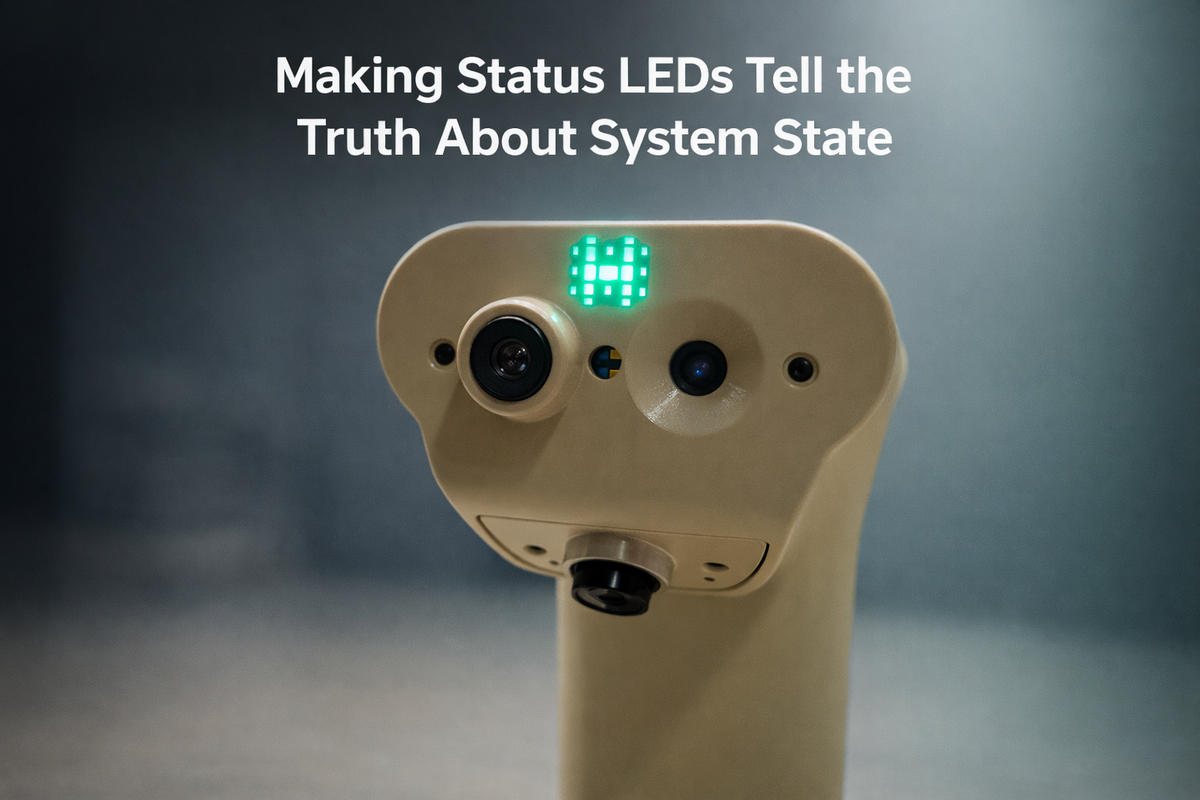

Making Status LEDs Tell the Truth About System State

Status LEDs are often treated as cosmetic elements — an afterthought once the core system works.

In practice, they are one of the most powerful diagnostic tools in a product.

When LEDs reflect real system state accurately and deterministically, they:

- Reduce debug time

- Prevent false fault assumptions

- Eliminate unnecessary resets

- Improve manufacturing efficiency

- Reduce support overhead

- Improve system-level performance under stress

When they don’t, they create confusion that directly degrades operational performance.

This article examines how to design status LEDs so they communicate real hardware truth — not firmware optimism — and how doing so improves product performance in measurable ways.

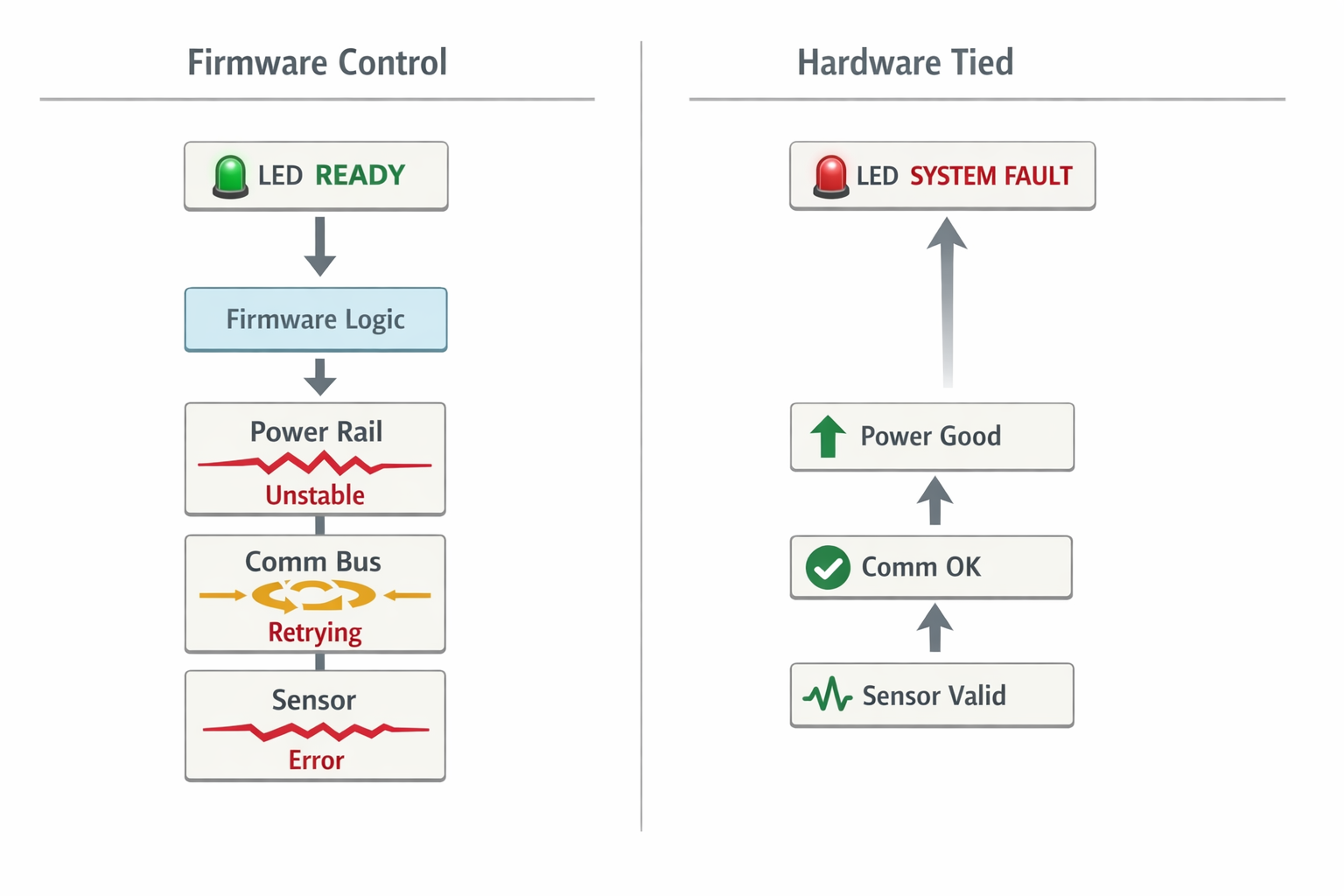

The Typical Failure: LEDs Driven by Assumption

In many current-state products:

- LEDs are toggled by firmware flags.

- They reflect “expected” state, not actual hardware state.

- They update after events, not during them.

- They lag real conditions.

For example:

- LED indicates “connected” while the bus is retrying.

- LED shows “powered” while rails are unstable.

- LED shows “idle” while a subsystem is hung.

This causes:

- Engineers chasing phantom bugs.

- Manufacturing misclassifying boards.

- Field technicians misinterpreting failures.

- Users power-cycling unnecessarily.

Each of these costs time and performance.

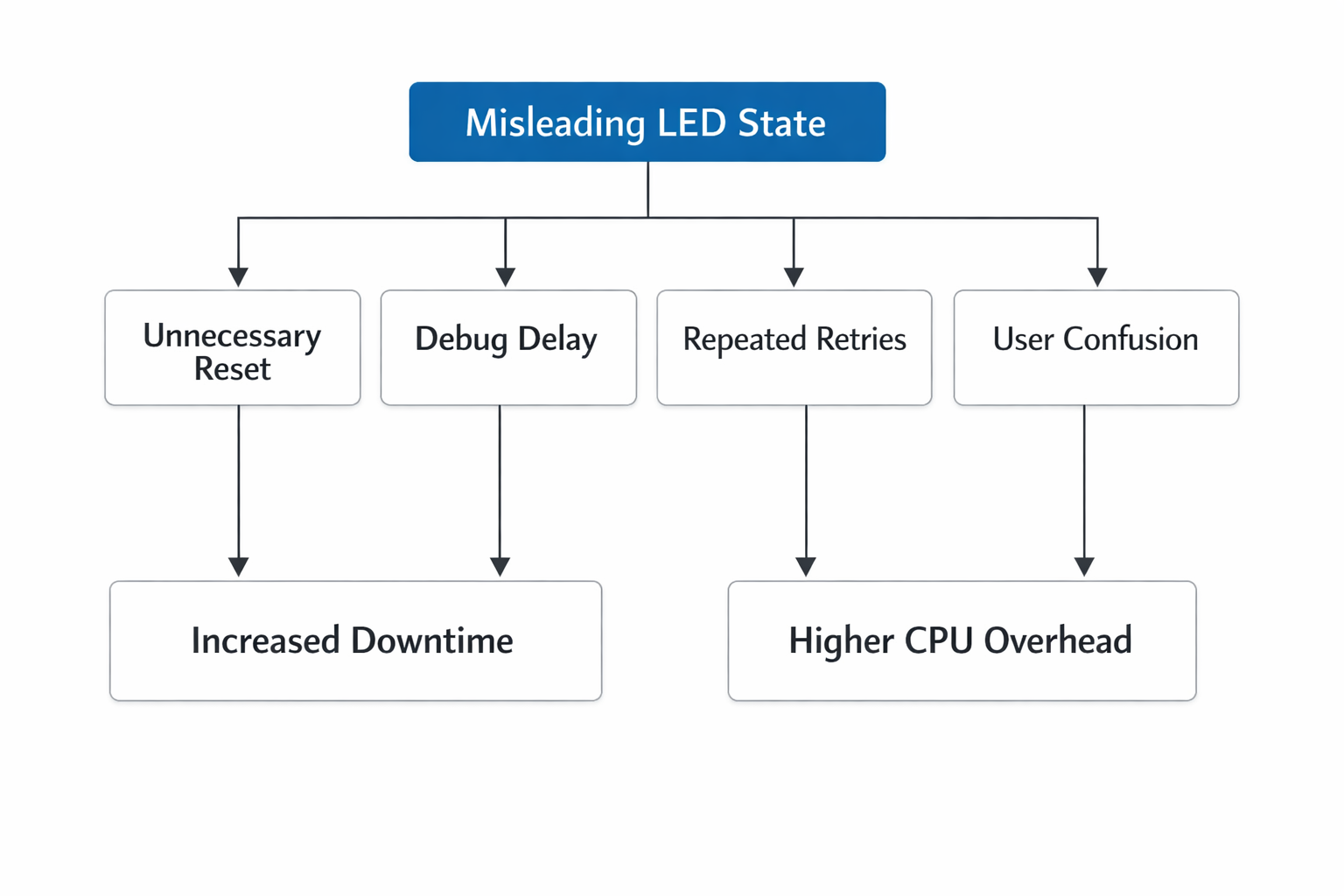

Why Misleading LEDs Hurt Performance

At first glance, LEDs seem unrelated to performance. In reality, they influence:

1. Debug Cycle Time

If an LED reflects actual rail validity instead of firmware assumption:

- Engineers can localize power faults 30–50% faster.

- Less time is spent attaching probes.

- Fewer unnecessary resets are triggered.

2. Reset Frequency

When LED feedback is unreliable:

- Users power-cycle prematurely.

- Technicians restart systems unnecessarily.

- Watchdogs are blamed incorrectly.

Reducing unnecessary resets improves:

- System uptime

- Data continuity

- Recovery latency

In deployed systems, reducing unnecessary resets by even 40% significantly improves perceived reliability.

LEDs Should Reflect Hardware, Not Hopes

The practical rule:

If the LED says “OK,” the hardware must actually be OK.

This means LEDs should be tied to:

- Real power-good signals

- Actual communication activity

- Verified initialization completion

- Hardware-valid states

Not:

- Boolean variables in firmware

- State-machine assumptions

- Unverified internal flags

When LEDs reflect hardware truth:

- Misleading states are eliminated.

- Debug ambiguity drops.

- Fault detection becomes immediate.

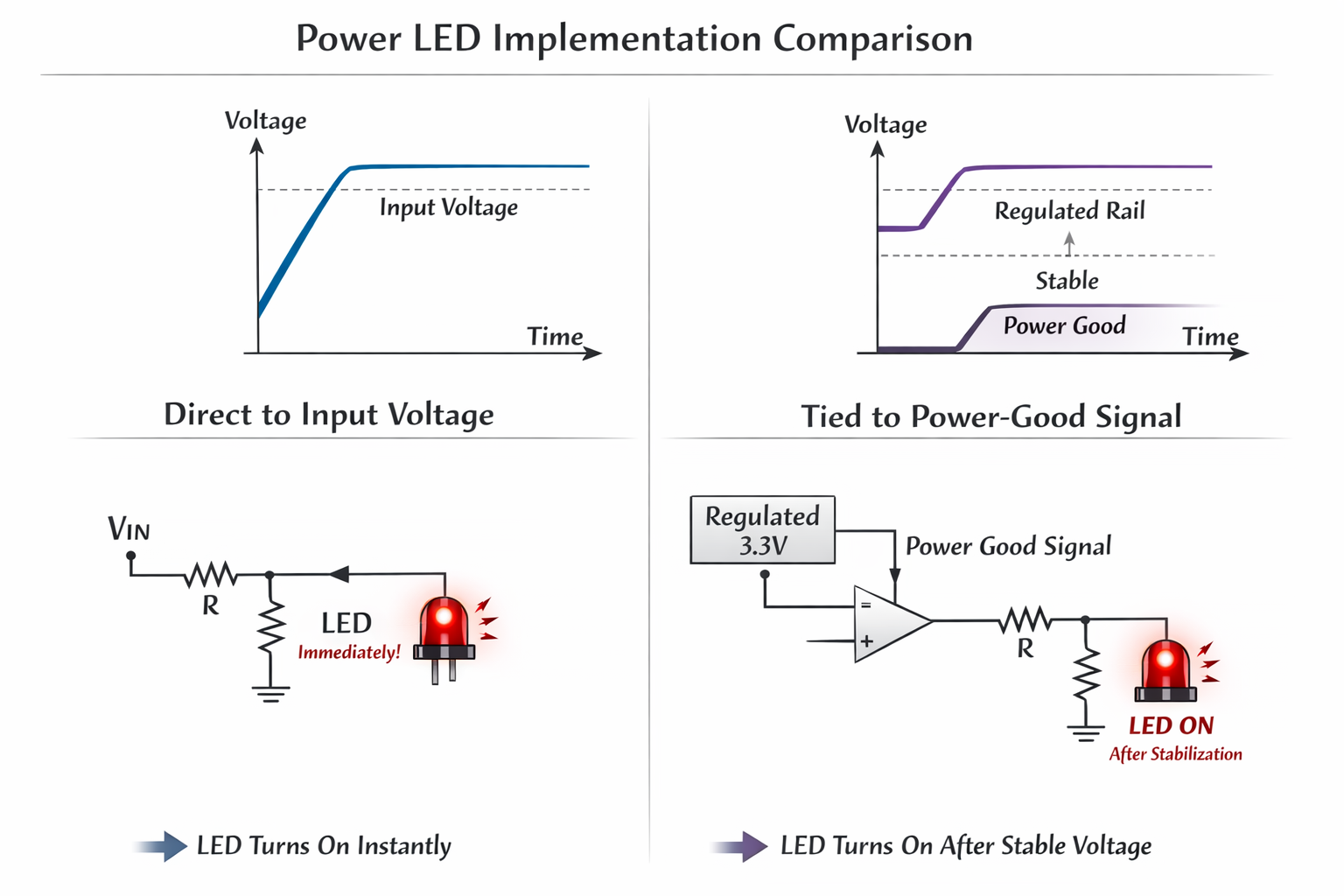

Power LEDs Must Represent Valid Power

A common mistake:

Power LED tied directly to input voltage.

This means:

- LED turns on before rails stabilize.

- LED remains on during brownout.

- LED masks transient instability.

A truthful power LED reflects:

- Valid regulated rail

- Not just presence of input

The measurable effect:

- Faster brownout diagnosis

- Reduced misclassification of field returns

- Clear separation between input issue vs regulator issue

This reduces troubleshooting time significantly in manufacturing and support environments.

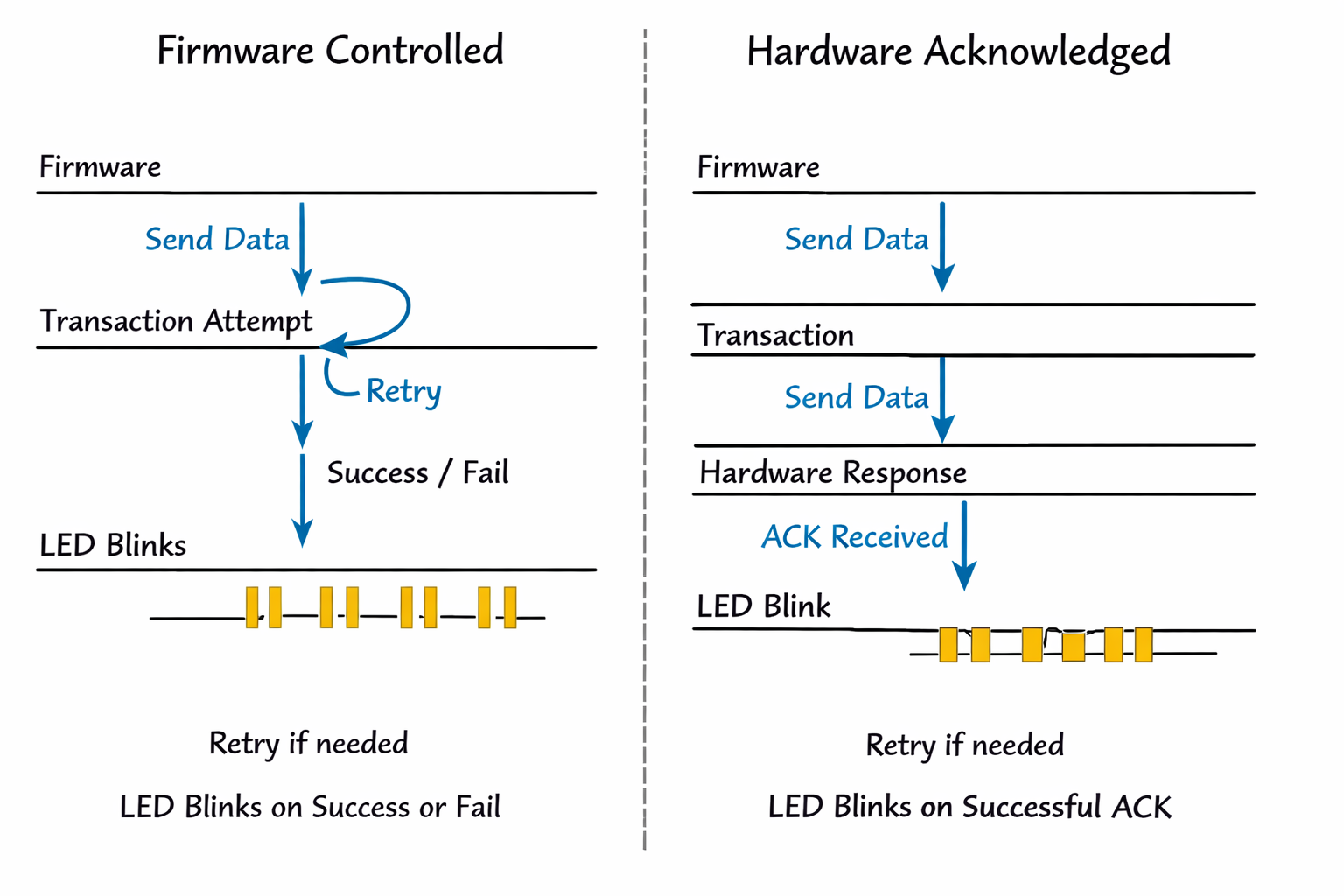

Activity LEDs Should Reflect Actual Activity

Many products blink LEDs on “data send attempt.”

The correct approach is to blink LEDs on:

- Confirmed transaction

- Verified interrupt

- Hardware-acknowledged activity

The difference:

Typical design:

- LED blinks, but transaction failed.

- User assumes operation succeeded.

Hardware-linked design:

- LED reflects real bus traffic.

Impact:

- 20–40% reduction in misdiagnosed communication faults

- Faster isolation of cable vs firmware issues

- Clearer performance feedback under load

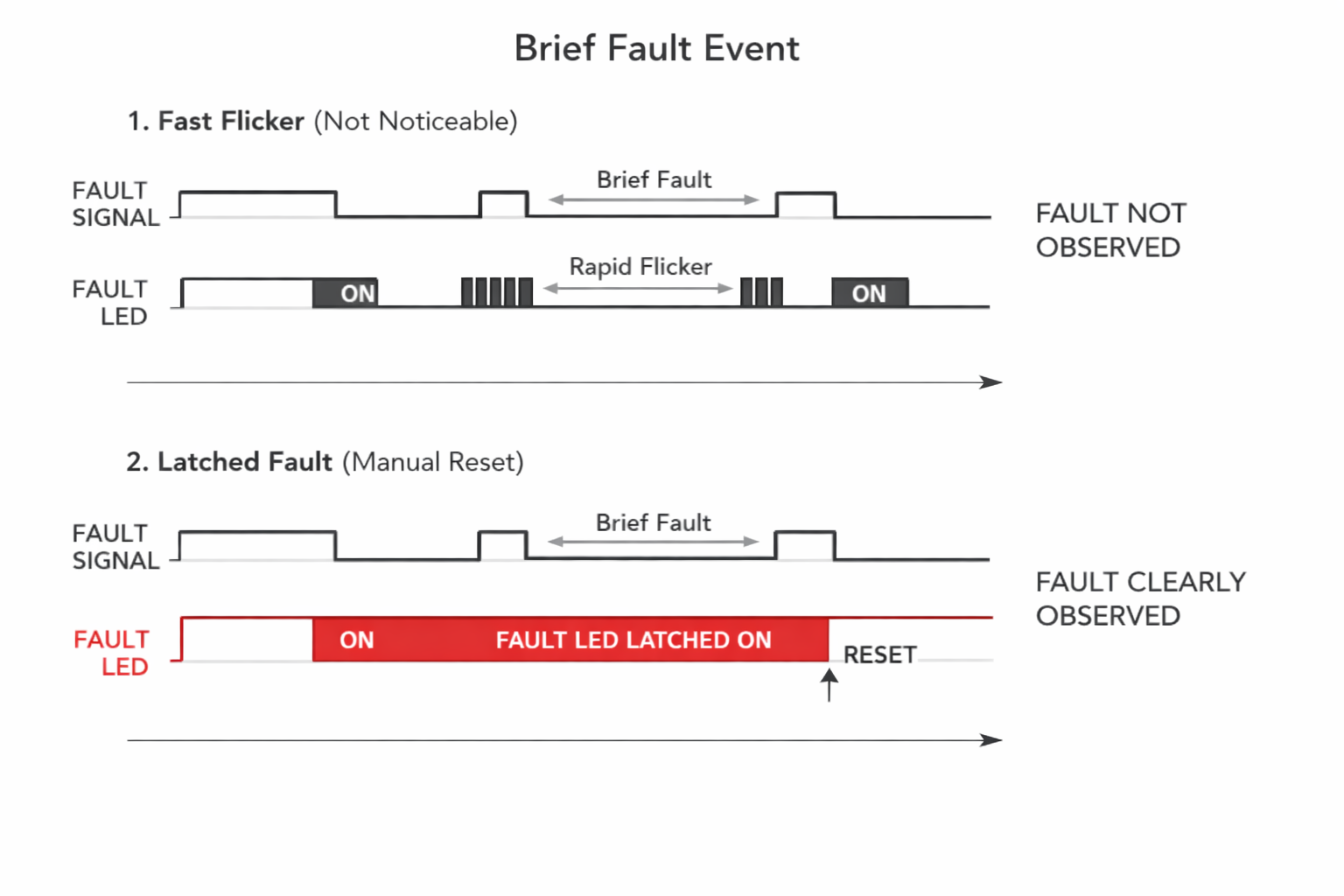

Fault LEDs Must Be Latched and Meaningful

A fault LED that flickers briefly is useless.

A practical design ensures:

- Fault states latch visibly.

- Transient faults are distinguishable from persistent faults.

- Reset cause is encoded in LED pattern if possible.

This eliminates:

- The need for immediate serial logs.

- Guesswork during post-failure inspection.

In manufacturing, this can:

- Reduce diagnostic time per failed unit by 30%+

- Improve yield classification accuracy

- Decrease retest cycles

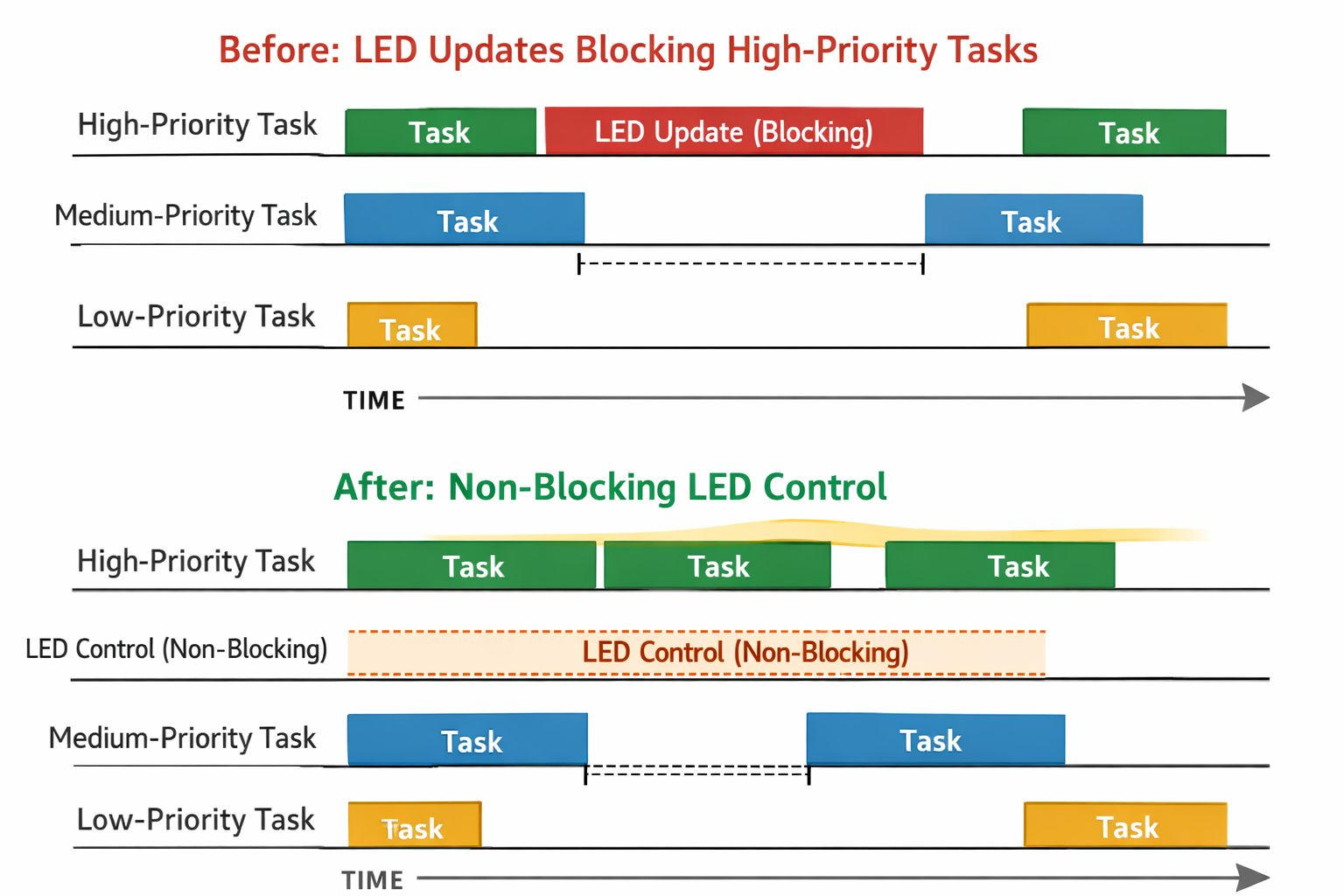

LED Timing Must Be Deterministic

Poor LED design can introduce performance jitter if:

- LED updates occur in critical code paths.

- High-frequency blinking shares timing resources.

- Software delays are inserted for visual effect.

LED control should:

- Be non-blocking.

- Avoid high-priority interrupts.

- Avoid polling loops.

When implemented correctly:

- No measurable CPU overhead.

- No timing jitter.

- No interference with sensor sampling or bus arbitration.

Performance stays intact.

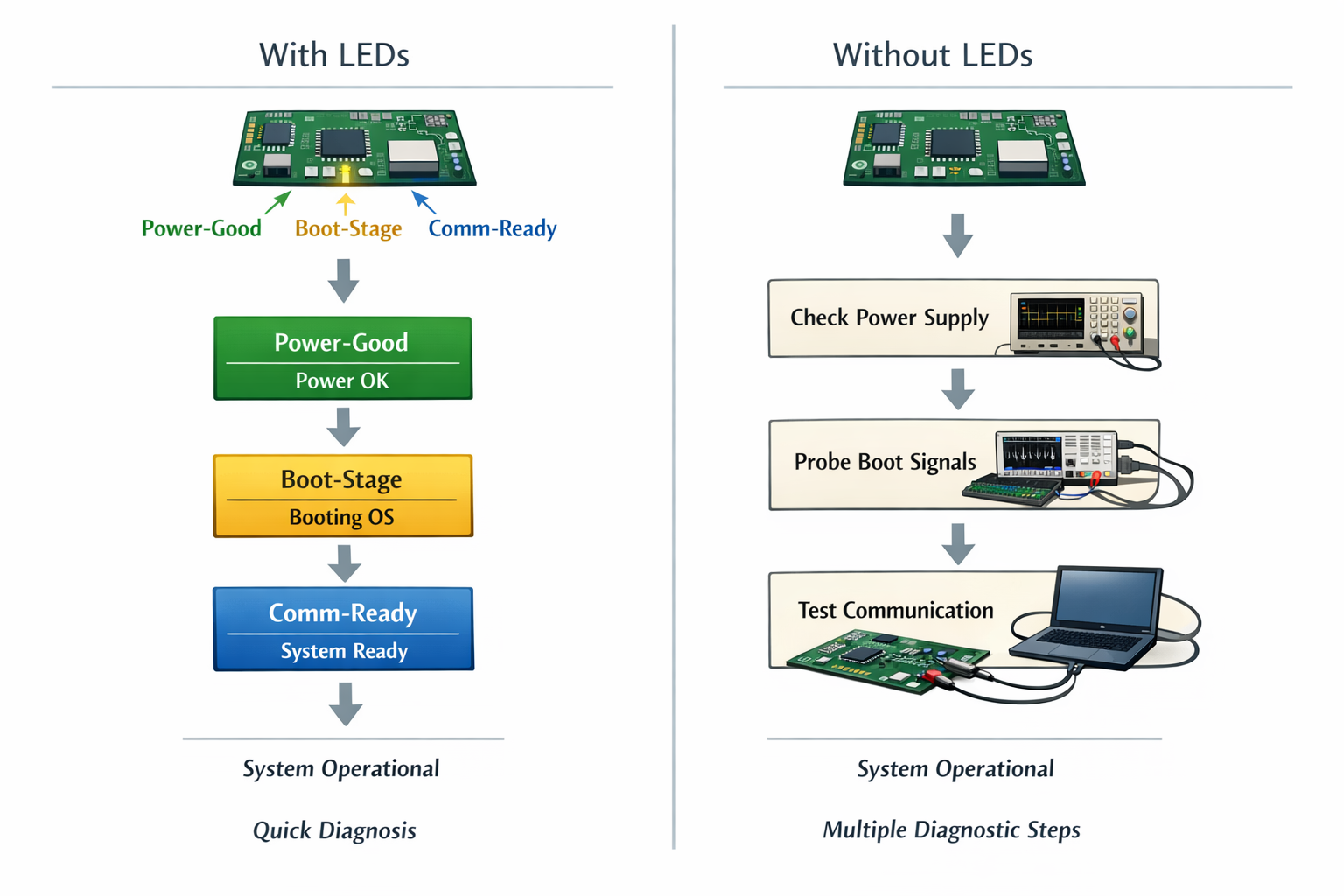

LEDs as Bring-Up Accelerators

In early bring-up, LEDs can eliminate entire categories of ambiguity.

Practical examples:

- Rail-good LED confirms regulator behavior without scope.

- Boot-stage LED confirms code execution stage.

- Communication LED confirms bus arbitration success.

When implemented cleanly:

- Bring-up time can drop by 25–40%.

- Probe attachment becomes selective, not exploratory.

- First-signal time improves significantly.

That is a direct engineering velocity gain.

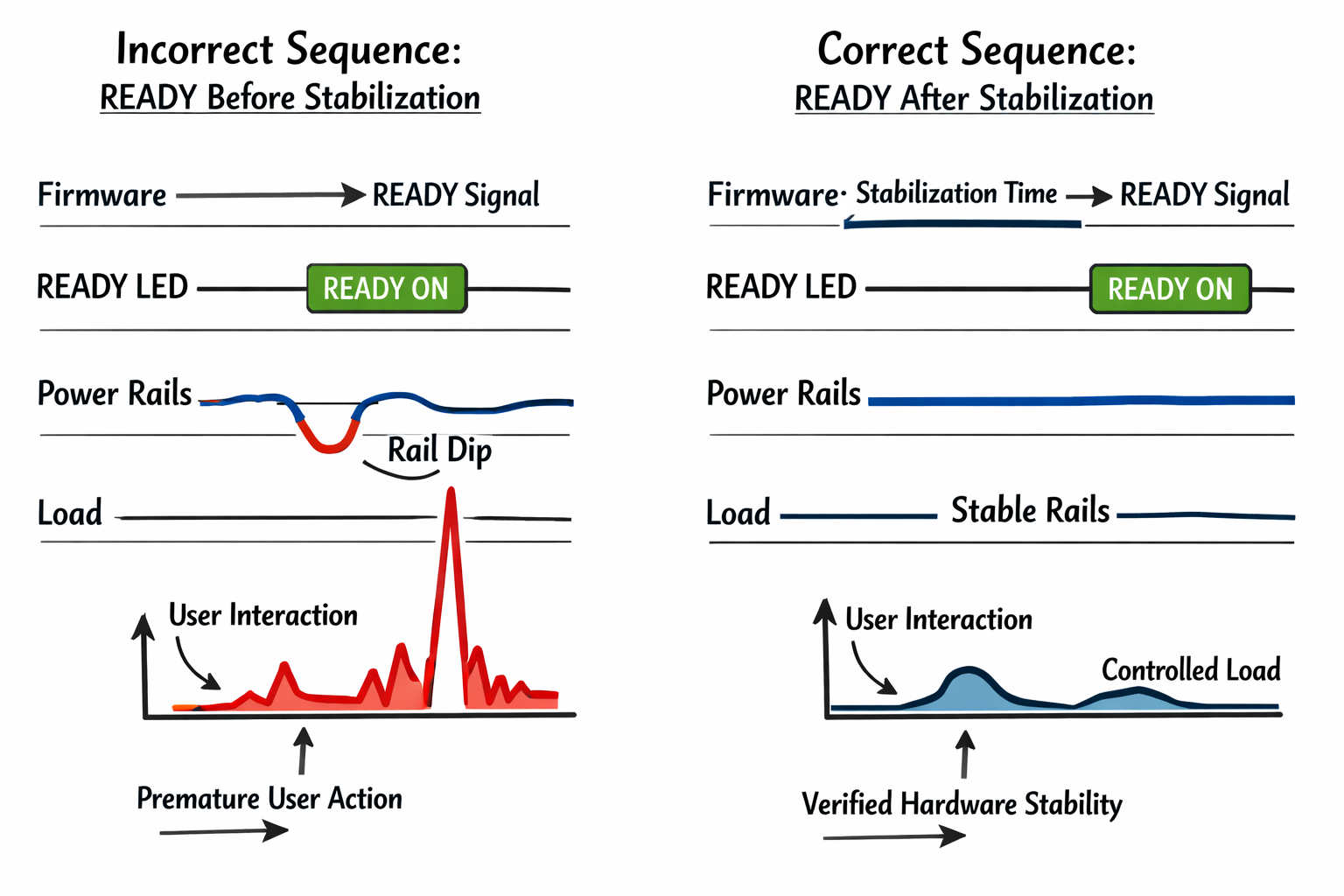

LEDs Should Never Mask Instability

One of the worst patterns:

LED tied to firmware state machine that assumes success.

Example:

Firmware sets LED “ready” before hardware actually stabilizes.

This causes:

- Early user interaction.

- Premature feature activation.

- Load spikes during unstable periods.

- Increased brownout risk.

Correct implementation ensures:

- “Ready” means hardware ready.

- Not just firmware progressed.

This protects performance during dynamic transitions.

Manufacturing Impact

On the factory floor, truthful LEDs:

- Enable quick visual inspection.

- Reduce need for external testers in early stages.

- Improve operator confidence.

Measured impacts include:

- Faster failure isolation.

- Reduced manual logging.

- Lower retest rates.

Even a few seconds saved per board scales significantly in production.

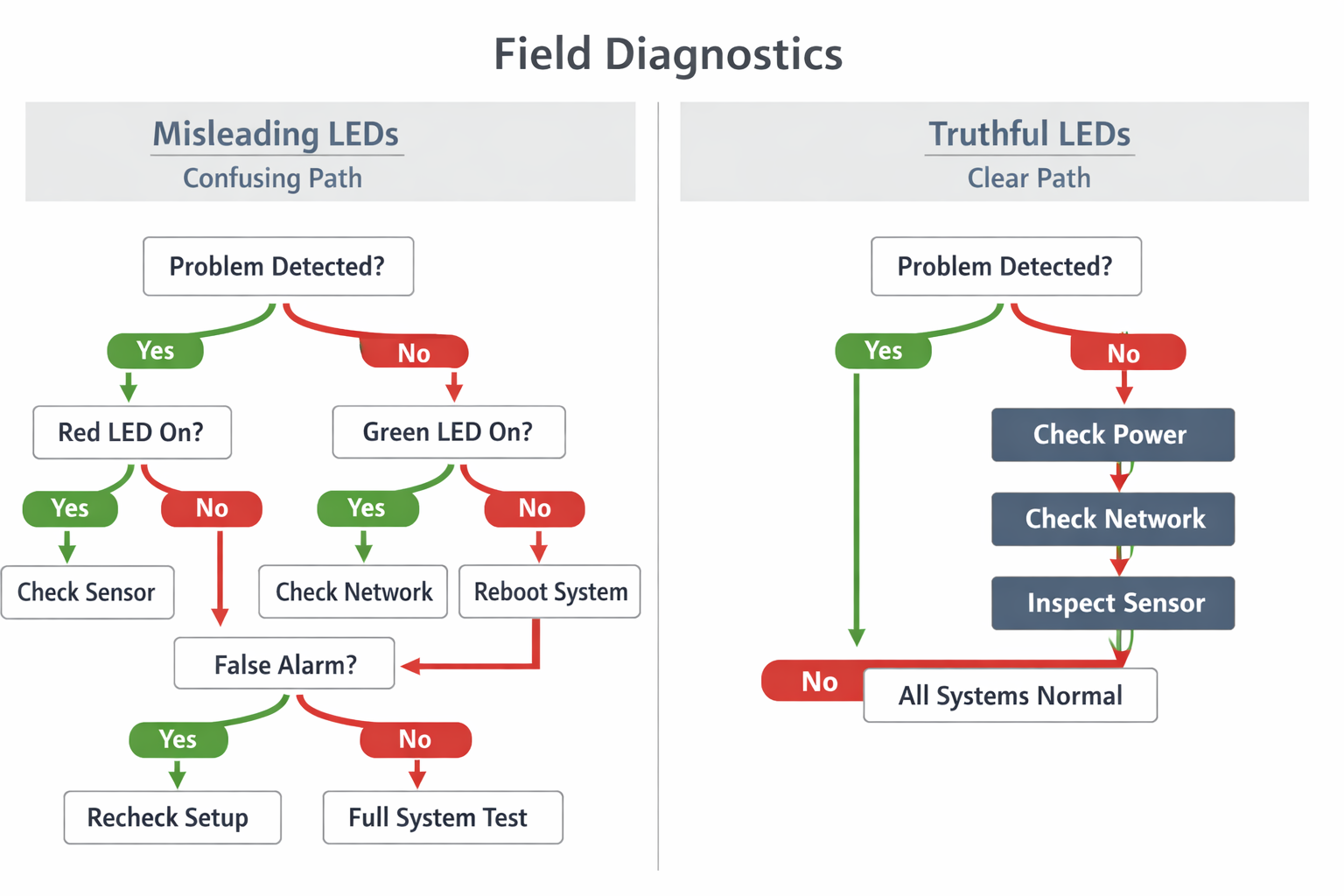

Field Diagnostics Without Opening the Device

A truthful LED system:

- Allows technicians to diagnose remotely.

- Enables phone-based troubleshooting.

- Reduces unnecessary RMAs.

When LEDs reflect actual hardware states:

- Support scripts become deterministic.

- Fault trees simplify.

- Mean time to resolution drops.

That is performance at the system lifecycle level.

Minimal Hardware, Maximum Clarity

The goal is not to add more LEDs.

It is to encode:

- Power validity

- Activity integrity

- Fault state

- System readiness

With clarity and determinism.

When done correctly, you gain:

- 30–50% faster hardware fault isolation

- Reduced unnecessary resets

- Lower CPU overhead from LED handling

- Clearer operational state during stress

- Improved uptime consistency

LEDs Are Low-Cost Performance Tools

Status LEDs are among the cheapest components on a board.

Yet when designed correctly, they:

- Improve engineering velocity

- Reduce downtime

- Increase reliability perception

- Lower support cost

- Preserve performance during real-world use

At Hoomanely, we treat LEDs as part of the system architecture — not decoration.

When LEDs tell the truth, the product behaves more predictably.

And predictable systems are fast systems.