Power Sequencing Firmware: Beyond Hardware - Software-Controlled Startup

How intelligent firmware orchestrates complex device initialization for reliable embedded systems

Introduction

In the world of embedded systems, the moment you press power is just the beginning of an intricate dance. While hardware designers focus on voltage rails and capacitors, firmware engineers face an equally critical challenge: ensuring every component powers up in the right sequence, at the right time, with proper fault handling. This software-controlled approach to power management has become essential in modern IoT devices, edge computing systems, and advanced monitoring equipment where reliability isn't optional—it's fundamental.

Power sequencing firmware transforms what could be chaotic hardware startup into a predictable, monitored, and recoverable process. Rather than relying solely on hardware power management ICs, sophisticated firmware state machines provide granular control, intelligent fault detection, and adaptive recovery mechanisms that hardware alone cannot achieve.

The Challenge: Why Software-Controlled Power Sequencing Matters

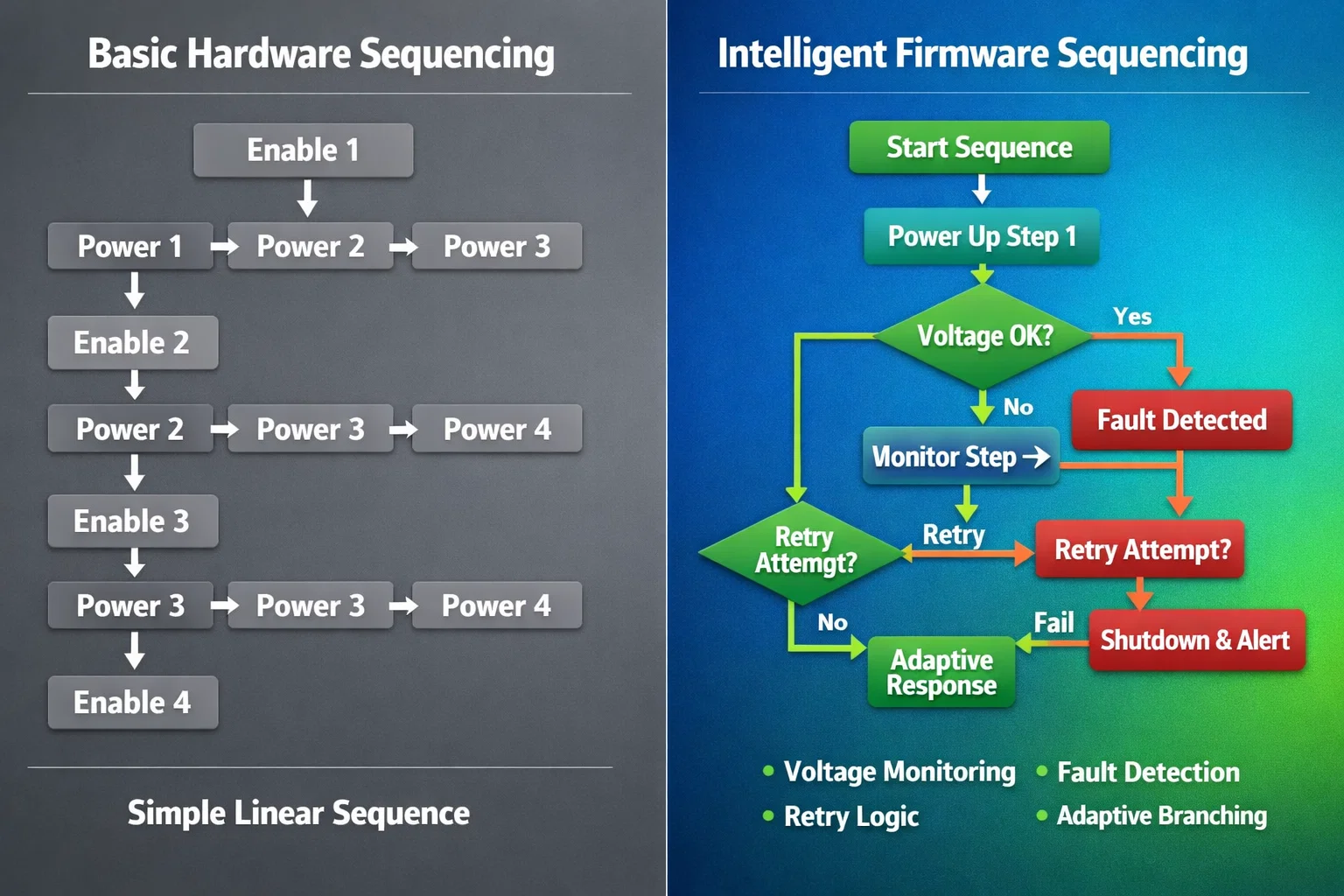

Traditional hardware-only power sequencing works for simple systems, but modern embedded devices demand more intelligence. Consider a multi-sensor edge computing device with camera modules, wireless transceivers, AI processing units, and external storage—each component has specific power-up timing requirements, voltage dependencies, and failure modes that need intelligent handling.

Key Challenges in Modern Power Sequencing:

Complex Dependencies: Modern devices often require specific power-up sequences where Component A must stabilize before Component B can safely initialize. A camera sensor might need its analog supply stable for 10ms before digital logic can be enabled, while wireless modules may require crystal oscillators to settle before attempting radio initialization.

Fault Detection and Recovery: Hardware-only solutions provide limited fault visibility. When something goes wrong during startup, you need intelligent firmware to detect the specific failure point, log diagnostic information, and implement appropriate recovery strategies—whether that's retrying the sequence, skipping non-critical components, or entering a safe diagnostic mode.

Dynamic Power Management: Advanced applications require runtime power state changes based on operating conditions. A pet monitoring device might need to dynamically enable/disable sensor modules based on activity detection or battery levels, requiring sophisticated state machine management beyond static hardware sequencing.

Diagnostic Capabilities: Professional-grade embedded systems need detailed startup telemetry for field troubleshooting and optimization. Firmware-controlled sequencing provides precise timing measurements, voltage monitoring data, and failure analytics that inform both immediate recovery decisions and long-term reliability improvements.

Architecture: Building Robust Power Sequencing State Machines

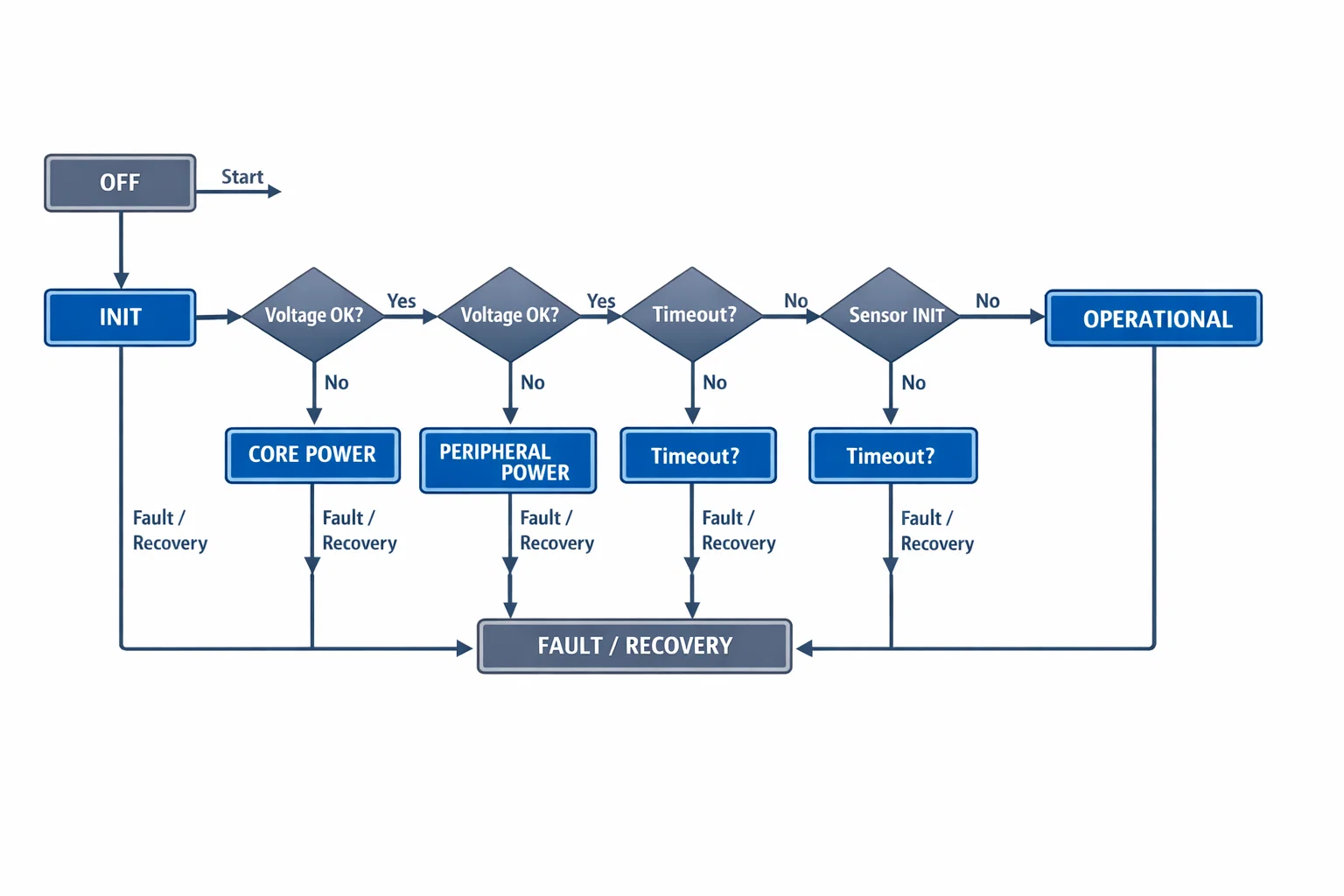

Effective power sequencing firmware centers around well-designed state machines that model the power-up process as discrete states with defined transitions, timeouts, and error handling. This approach provides predictable behavior while maintaining flexibility for complex scenarios.

Core State Machine Design

typedef enum {

POWER_STATE_OFF,

POWER_STATE_INIT,

POWER_STATE_CORE_POWER,

POWER_STATE_PERIPHERAL_POWER,

POWER_STATE_SENSOR_INIT,

POWER_STATE_COMMS_INIT,

POWER_STATE_OPERATIONAL,

POWER_STATE_FAULT,

POWER_STATE_RECOVERY

} power_state_t;

typedef struct {

power_state_t current_state;

uint32_t state_entry_time;

uint32_t timeout_ms;

uint8_t retry_count;

fault_code_t last_fault;

} power_sequencer_t;

The state machine approach provides several advantages: Clear State Visibility allows easy debugging and monitoring of the current power state, Timeout Protection prevents hanging in any single state due to hardware faults, Retry Logic enables graceful handling of transient failures, and Fault Isolation makes it easy to identify exactly where in the sequence problems occur.

GPIO Control Strategy

Modern power sequencing often involves controlling multiple enable pins, power switches, and reset signals through GPIO. The key is organizing these controls into logical groups with proper timing relationships:

typedef struct {

GPIO_TypeDef* port;

uint16_t pin;

uint32_t delay_after_ms;

bool active_high;

} power_control_t;

// Power sequence configuration

static const power_control_t core_power_seq[] = {

{GPIOA, GPIO_PIN_0, 5, true}, // Primary regulator enable

{GPIOA, GPIO_PIN_1, 10, true}, // Secondary regulator enable

{GPIOB, GPIO_PIN_2, 15, false}, // Reset release (active low)

};

This structured approach ensures consistent timing, makes sequences easily configurable, and provides a clear framework for adding new power domains as systems evolve.

Implementation: Voltage Monitoring and Fault Detection

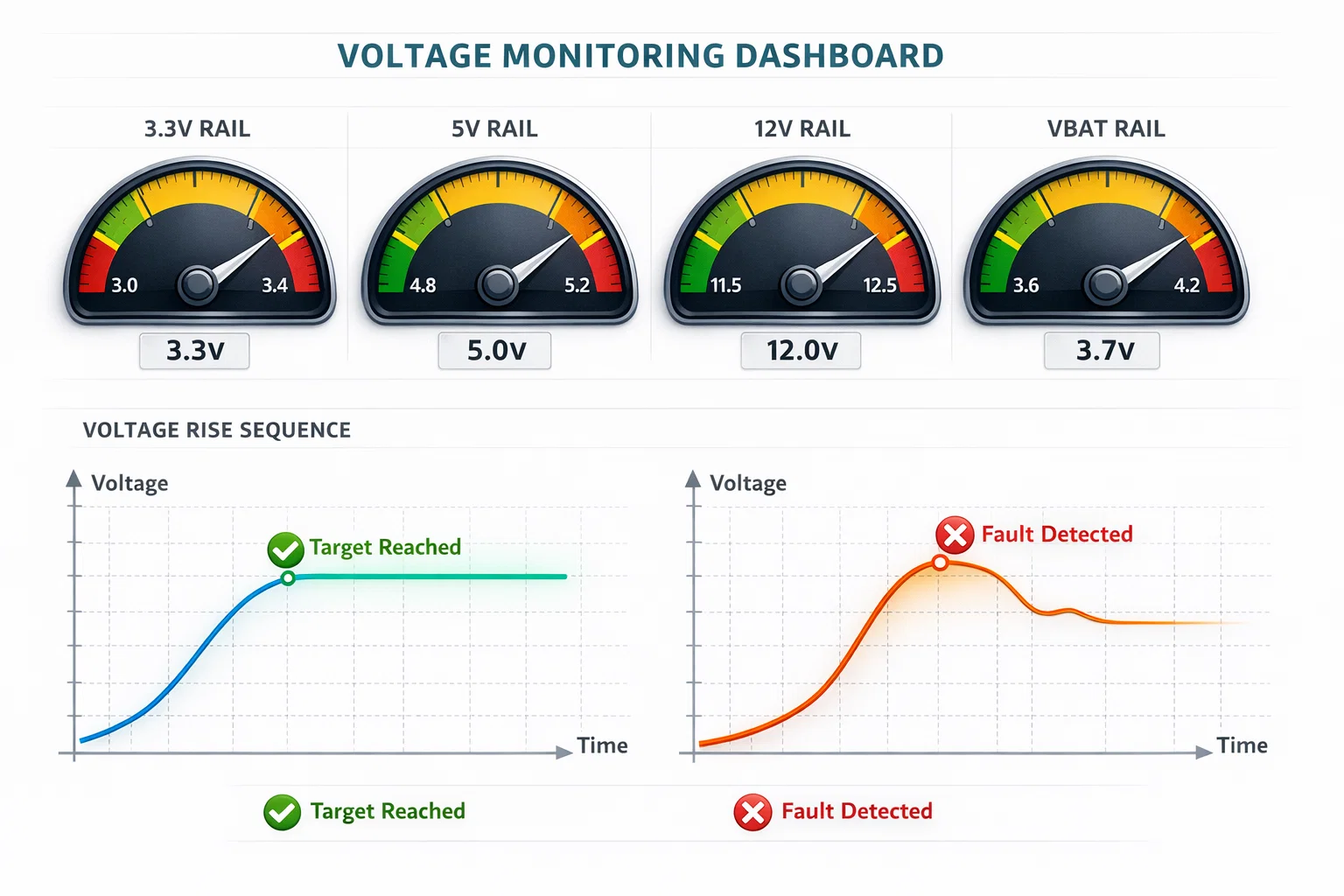

Reliable power sequencing requires continuous monitoring of system voltages and intelligent fault detection. The ADC becomes a critical sensor for the power management system, providing real-time feedback on power rail health.

Advanced Voltage Monitoring

typedef struct {

uint16_t nominal_mv;

uint16_t tolerance_percent;

uint16_t settling_time_ms;

uint8_t adc_channel;

} voltage_monitor_t;

bool check_voltage_rail(const voltage_monitor_t* monitor) {

uint16_t measured_mv = read_adc_voltage(monitor->adc_channel);

uint16_t tolerance = (monitor->nominal_mv * monitor->tolerance_percent) / 100;

return (measured_mv >= (monitor->nominal_mv - tolerance)) &&

(measured_mv <= (monitor->nominal_mv + tolerance));

}

The firmware continuously samples critical voltage rails during power sequencing, comparing measured values against expected ranges. This real-time monitoring catches brown-out conditions, regulator failures, or excessive voltage ripple that could damage downstream components.

Intelligent Fault Detection Algorithms

Beyond simple voltage range checking, sophisticated fault detection looks for patterns and trends that indicate developing problems:

Voltage Settling Analysis: Monitoring how quickly voltages reach their target values can detect weak regulators, excessive load conditions, or marginal power supply designs before they cause system failures.

Startup Current Monitoring: Measuring current consumption during power sequencing helps identify components that aren't initializing properly or are drawing excessive power due to faults.

Temperature Correlation: Cross-referencing power sequencing behavior with temperature data helps distinguish between environmental-related startup issues and component failures.

Recovery Strategy Implementation

When faults occur, the recovery strategy depends on the fault type and system criticality requirements:

void handle_power_fault(fault_code_t fault_code) {

switch(fault_code) {

case FAULT_VOLTAGE_LOW:

if(retry_count < MAX_RETRIES) {

delay_ms(RETRY_DELAY);

restart_power_sequence();

} else {

enter_safe_mode();

}

break;

case FAULT_TIMEOUT:

log_detailed_diagnostics();

skip_non_critical_components();

continue_sequence();

break;

case FAULT_OVERCURRENT:

immediate_shutdown();

log_critical_fault();

break;

}

}

This tiered approach allows systems to gracefully degrade functionality while maintaining core operations, crucial for applications where complete system failure is unacceptable.

Image Prompt 2: Design an infographic showing voltage monitoring dashboard with 4 power rails (3.3V, 5V, 12V, VBAT) displayed as analog gauge meters with green/yellow/red zones. Include timeline graphs showing voltage rise curves during power-on sequence, with clear markers for "Target Reached" and "Fault Detected" points. Use clean, technical dashboard style with dark background.

Advanced Techniques: Handling Edge Cases and Optimization

Real-world power sequencing encounters numerous edge cases that simple state machines can't handle effectively. Professional implementations incorporate advanced techniques for robust operation across diverse conditions.

Dynamic Sequencing Based on System State

Rather than using fixed sequences, advanced systems adapt their power-up behavior based on the previous shutdown state, available power sources, and detected hardware configuration:

void determine_power_sequence(void) {

system_config_t config = detect_hardware_config();

power_source_t source = get_power_source();

shutdown_reason_t last_shutdown = get_shutdown_reason();

if(last_shutdown == SHUTDOWN_WATCHDOG_RESET) {

// Skip non-critical components for faster recovery

use_minimal_power_sequence();

} else if(source == POWER_SOURCE_BATTERY && get_battery_level() < 20) {

// Reduce power consumption during low battery startup

use_low_power_sequence();

} else {

use_full_power_sequence();

}

}

This adaptive approach optimizes startup time and power consumption while maintaining system reliability across different operating scenarios.

Power State Persistence and Fast Resume

Modern systems benefit from storing power state information in non-volatile memory, enabling intelligent resume capabilities:

State Checkpointing: Saving critical power state information before shutdown allows faster startup by skipping components that were already properly initialized.

Component Health Tracking: Maintaining historical data on component startup behavior helps predict potential failures and adjust timeout values dynamically.

Energy Budget Management: Tracking power consumption patterns during startup helps optimize sequences for battery-powered applications.

Temperature and Environmental Compensation

Power sequencing behavior often needs adjustment based on environmental conditions:

uint32_t calculate_settling_time(voltage_monitor_t* monitor) {

int8_t temperature = get_system_temperature();

uint32_t base_time = monitor->settling_time_ms;

if(temperature < -10) {

// Cold temperature increases settling time

return base_time * 1.5;

} else if(temperature > 60) {

// High temperature may cause faster settling

return base_time * 0.8;

}

return base_time;

}

This environmental awareness ensures reliable operation across the full operating temperature range, critical for outdoor or automotive applications.

Real-World Application: Power Management in Edge AI Systems

Modern edge computing applications, particularly in IoT and monitoring systems, demonstrate the critical importance of sophisticated power sequencing. These devices often combine multiple processors, sensor arrays, wireless communication modules, and storage components—each with specific power requirements and interdependencies.

Multi-Domain Power Architecture

Consider a comprehensive monitoring system that integrates:

- Core Processing Unit: Main application processor requiring stable power before peripheral initialization

- AI Acceleration Hardware: Specialized compute units needing precise voltage sequencing and thermal management

- Sensor Array: Multiple environmental, motion, and imaging sensors with varying power-up times

- Communication Modules: Wireless transceivers requiring crystal stabilization and RF calibration

- Storage Systems: Non-volatile memory requiring specific write voltage sequences

The power sequencing firmware must orchestrate these components while handling real-time constraints, power budget limitations, and fault tolerance requirements.

Smart Recovery and Graceful Degradation

Professional-grade systems implement intelligent degradation strategies when power sequencing encounters problems:

void handle_sensor_init_failure(sensor_id_t failed_sensor) {

// Log failure for diagnostics

log_sensor_fault(failed_sensor, get_timestamp());

// Determine if system can operate without this sensor

if(is_critical_sensor(failed_sensor)) {

enter_diagnostic_mode();

} else {

// Continue with reduced functionality

disable_features_requiring_sensor(failed_sensor);

mark_system_degraded();

continue_normal_operation();

}

}

This approach ensures maximum system availability even when individual components fail, crucial for applications where downtime has significant consequences.

Debugging and Optimization Strategies

Effective power sequencing firmware includes comprehensive debugging capabilities essential for development and field troubleshooting.

Telemetry and Logging Systems

typedef struct {

uint32_t timestamp;

power_state_t state;

uint16_t voltage_readings[MAX_VOLTAGE_RAILS];

uint16_t current_consumption;

int8_t temperature;

fault_code_t fault_status;

} power_log_entry_t;

Detailed logging provides insights into power sequencing behavior, enabling optimization of timeout values, identification of marginal components, and prediction of potential failures before they impact system operation.

Performance Optimization

Parallel Initialization: Where hardware allows, initializing independent components in parallel rather than sequentially reduces overall startup time.

Predictive Timeouts: Using historical timing data to adjust timeout values dynamically improves reliability while minimizing unnecessary delays.

Power Budget Optimization: Monitoring actual power consumption during sequencing helps optimize sequences for battery life and thermal management.

Connection to Advanced Monitoring Technology

This sophisticated approach to power sequencing becomes particularly relevant in applications requiring high reliability and continuous operation. In the realm of advanced pet healthcare technology, where devices must operate reliably for extended periods while providing continuous monitoring capabilities, robust power management isn't just a technical detail—it's fundamental to the user experience and animal welfare.

Hoomanely's Technology Vision

At Hoomanely, we're developing next-generation pet healthcare technology that combines sensor fusion, edge AI, and smart ML models to decode every moment of our pets' lives. Our mission of "Healthcare for pets, reinvented" through continuous monitoring and proactive health insights requires embedded systems that operate flawlessly in diverse environments—from indoor comfort to outdoor adventures.

The power sequencing techniques discussed in this article directly support Hoomanely's technology stack:

Physical Intelligence Devices: Our smart devices with sensor fusion capabilities require precise power management to ensure all sensors initialize correctly and maintain synchronized operation for accurate health data collection.

Edge AI Processing: The Biosense AI Engine running on edge devices demands reliable power sequencing to ensure consistent performance of machine learning inference, particularly critical when processing real-time health data that could indicate emergency situations.

Continuous Monitoring Requirements: Pet healthcare monitoring can't afford unexpected downtime due to power sequencing failures. The fault detection and recovery algorithms described here ensure maximum system availability, supporting our goal of providing continuous health insights to strengthen human-animal bonds.

By implementing sophisticated firmware-controlled power sequencing, Hoomanely's devices can maintain the reliability and performance needed to deliver clinical-grade health intelligence that truly transforms pet care from reactive to predictive.

Key Takeaways

Firmware-controlled power sequencing represents a fundamental shift from reactive to proactive power management in embedded systems. The key insights for implementing robust power sequencing include:

- State Machine Architecture: Well-designed state machines provide predictable behavior while maintaining flexibility for complex scenarios and edge cases.

- Comprehensive Monitoring: Real-time voltage and current monitoring, combined with intelligent fault detection algorithms, enables proactive problem identification and resolution.

- Adaptive Recovery Strategies: Tiered fault handling approaches allow systems to gracefully degrade functionality while maintaining core operations, maximizing system availability.

- Environmental Awareness: Adjusting power sequencing behavior based on temperature, power source, and system history optimizes performance across diverse operating conditions.

- Diagnostic Integration: Comprehensive logging and telemetry capabilities are essential for both development optimization and field troubleshooting.

As embedded systems become increasingly complex and reliability requirements continue to grow, sophisticated power sequencing firmware transforms from a nice-to-have feature into a fundamental requirement. Whether you're developing IoT devices, edge computing systems, or advanced monitoring equipment, investing in robust power management pays dividends in system reliability, user experience, and long-term product success.

The techniques outlined here provide a foundation for building power sequencing systems that handle real-world complexities while maintaining the reliability and performance that modern applications demand.

About the Author: This technical deep dive into power sequencing firmware reflects real-world experience developing reliable embedded systems for mission-critical applications, where robust power management directly impacts product success and user trust.