Rapid Prototyping with SLA and FDM

Choosing the Right Path from Geometry to User Reality

Speed matters—but only when it’s paired with intent.

At Hoomanely, getting a product into users’ hands early is not a race against time; it’s a strategy to surface real-world constraints that no simulation or review can fully predict. Enclosure feel, grip comfort, visual proportion, connector accessibility, structural robustness—these are qualities that only emerge when a product is physically experienced. Rapid prototyping enables that experience, but the real leverage comes from how we prototype.

SLA and FDM are not interchangeable tools in our workflow. They represent two distinct prototyping philosophies, each optimised for different questions we want to answer at different stages of product evolution. By choosing between them deliberately—and often using both in parallel—we compress iteration cycles without compromising mechanical integrity, precision, or long-term design intent.

This blog explores how SLA and FDM fit into our rapid prototyping framework, how we decide which process to use, and how that discipline allows us to move quickly while still designing products that age well in the real world.

Prototyping as a Design Instrument, Not a Shortcut

Rapid prototyping is often misunderstood as a way to “print something fast.” In practice, it’s a way to validate assumptions early, before design decisions harden into tooling, supply chains, and production commitments.

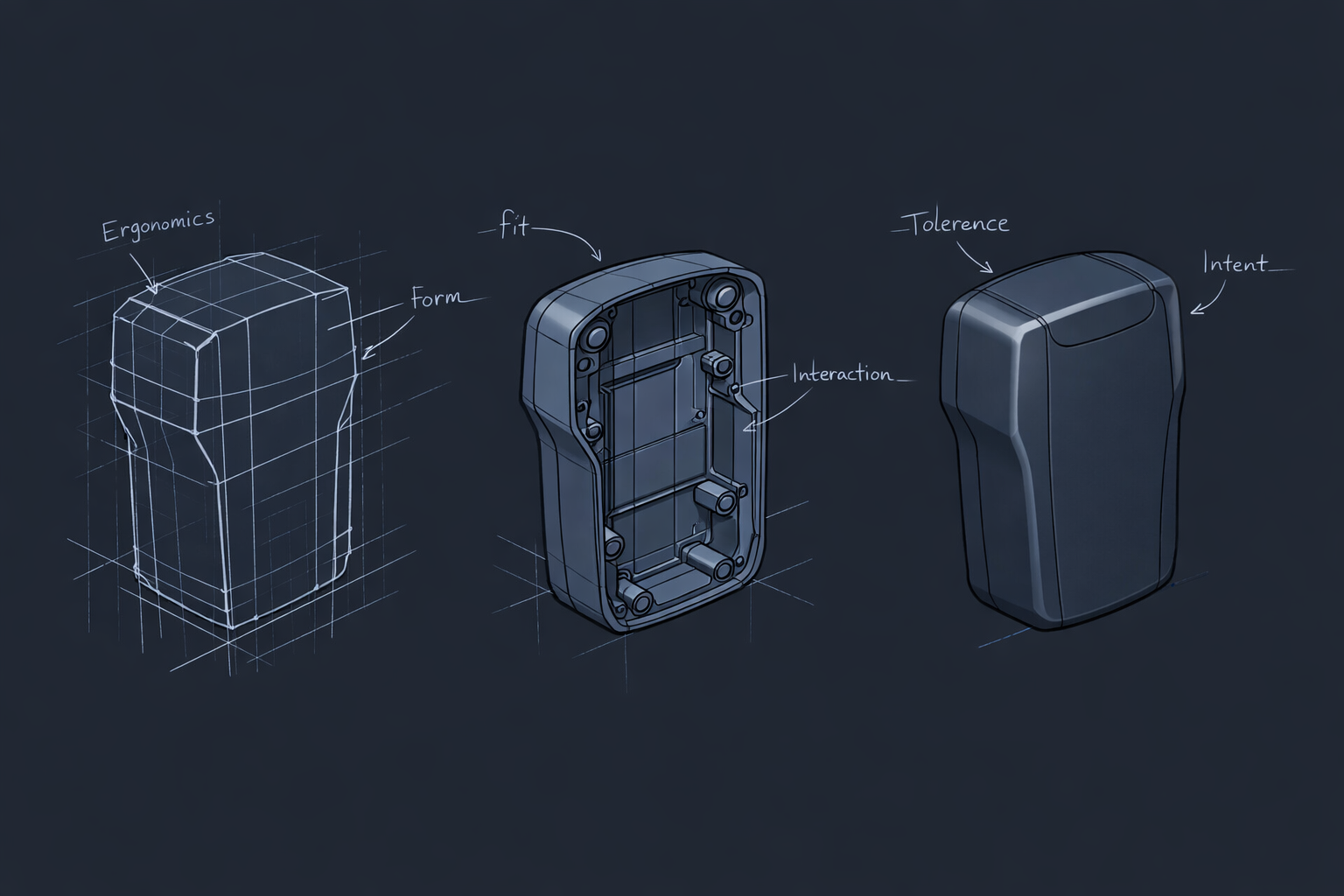

Our products involve complex geometries—curved enclosures, organic surfaces, internal ribs, tight clearances around electronics, and structural load paths that must survive daily use. These characteristics make it impossible to rely on a single prototyping method. Instead, we treat prototyping as a staged instrument:

- Early-stage geometry and ergonomics

- Mid-stage fit, assembly, and interaction

- Late-stage tolerance confidence and visual intent

SLA and FDM each excel at different layers of this validation stack.

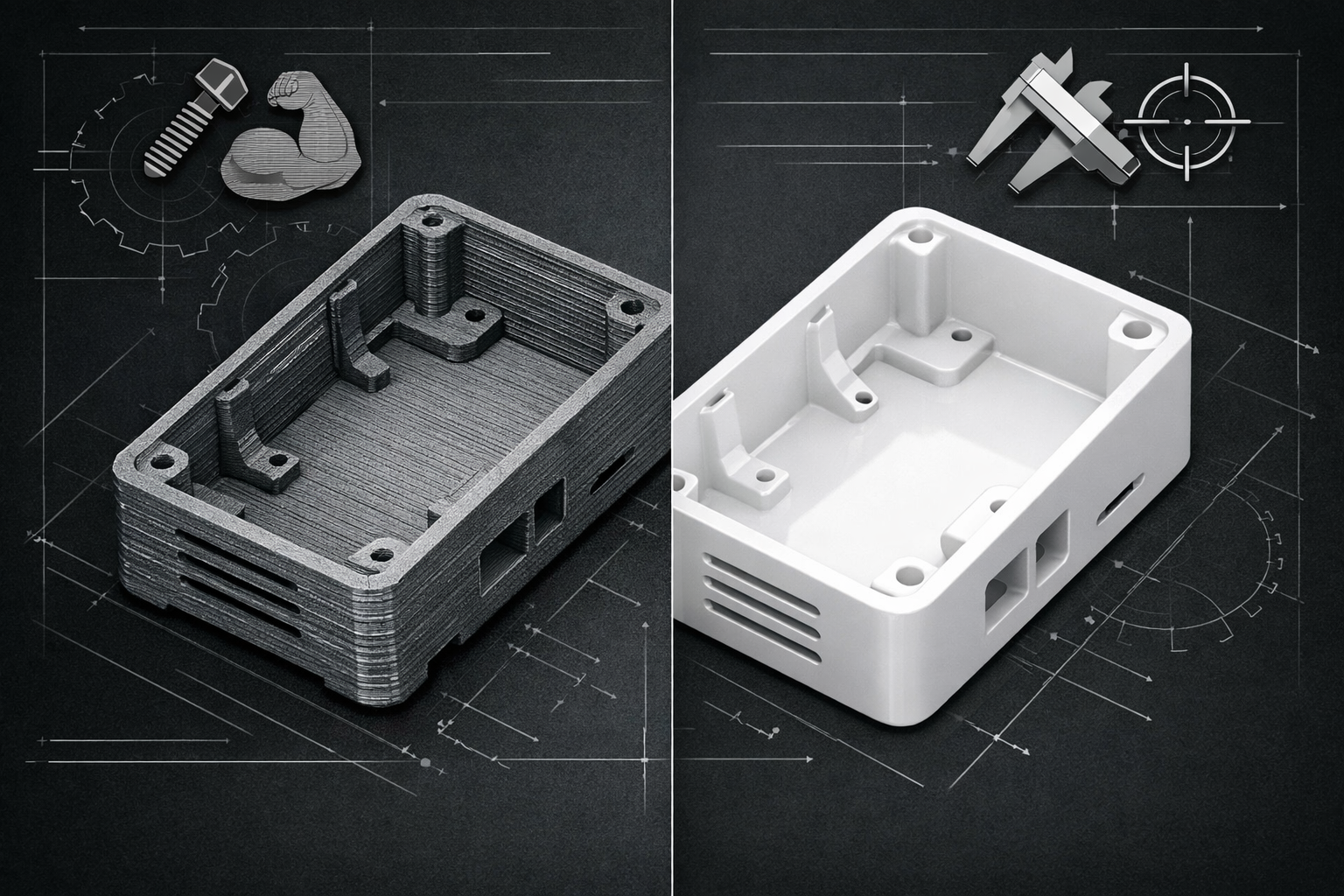

FDM: Structural Intent and Mechanical Confidence

FDM is our workhorse when the question is “Will this survive real use?”

Why FDM Matters

FDM prints allow us to explore mechanical behavior early—wall thickness decisions, rib placement, snap strength, and overall enclosure rigidity. The layered nature of FDM, often seen as a drawback, actually provides valuable signal: if a design survives FDM stresses, it’s directionally sound for injection-molded plastics with superior material properties.

For Hoomanely products, FDM is especially valuable when:

- Evaluating structural durability of curved or cantilevered sections

- Testing mounting interfaces between enclosures and internal frames

- Validating assembly forces for press-fits, clips, and screw bosses

- Checking drop and torsion resilience in handheld or floor-mounted devices

Material Choices That Matter

We do not treat filament choice casually. PETG, ABS, and reinforced filaments are selected based on what behaviour we want to approximate—impact absorption, flex tolerance, or stiffness. This allows FDM prototypes to serve as mechanical surrogates, not just visual stand-ins.

FDM answers questions like:

- Does this enclosure flex too much under grip pressure?

- Will this boss crack under repeated torque?

- Is this rib actually contributing to stiffness, or just adding complexity?

If the answer is “no” at this stage, the design is reshaped immediately—long before any cosmetic considerations enter the picture.

SLA: Precision, Fit, and Visual Truth

Where FDM validates strength, SLA validates truth.

SLA printing gives us access to fine detail, sharp edges, smooth surfaces, and tight dimensional accuracy—qualities essential for understanding how a product will feel and assemble in its final form.

When SLA Becomes Essential

SLA is chosen when we need confidence in:

- Connector alignment and port cutouts

- Tight internal clearances between PCB, battery, and enclosure walls

- Optical elements, light guides, and indicator windows

- User-facing surfaces, seams, and parting lines

For products with curved ABS enclosures, SLA allows us to evaluate how those curves visually resolve in the hand—something CAD alone cannot convey. Small radius transitions, edge breaks, and surface continuity become immediately apparent.

SLA prototypes often answer:

- Does this enclosure look and feel “finished”?

- Are seams visually distracting?

- Do tolerances stack cleanly during assembly?

This is where industrial design intent meets mechanical reality.

DFM Thinking During Prototyping

A key principle in our workflow is that rapid prototyping is not separate from DFM—it feeds it.

FDM and DFM Alignment

FDM helps us identify features that will be difficult or unnecessary in moulding:

- Overly aggressive ribs

- Deep unsupported cavities

- Snap geometries that rely on unrealistic flexibility

By simplifying or strengthening these features early, we reduce risk in later tooling decisions.

SLA and DFM Alignment

SLA allows us to validate:

- Draft feasibility without visually compromising surfaces

- Wall thickness consistency across curved forms

- Whether the tolerance requirements are realistic for mass production

Even though SLA can exceed production-level precision, it helps us set upper bounds on what the design expects—ensuring we don’t unknowingly depend on impossible manufacturing accuracy.

Choosing Between SLA and FDM: A Deliberate Trade-Off

At Hoomanely, the decision isn’t “SLA or FDM?”—it’s “What question are we trying to answer today?”

| Design Question | Preferred Method |

|---|---|

| Structural durability | FDM |

| Assembly force and robustness | FDM |

| Ergonomics and grip | FDM (early), SLA (refinement) |

| Tight fit and alignment | SLA |

| Surface quality and seams | SLA |

| Internal clearance validation | SLA |

| Early form exploration | FDM |

| Late-stage enclosure confidence | SLA |

Often, the same enclosure exists in both forms simultaneously—each revealing different truths about the same geometry.

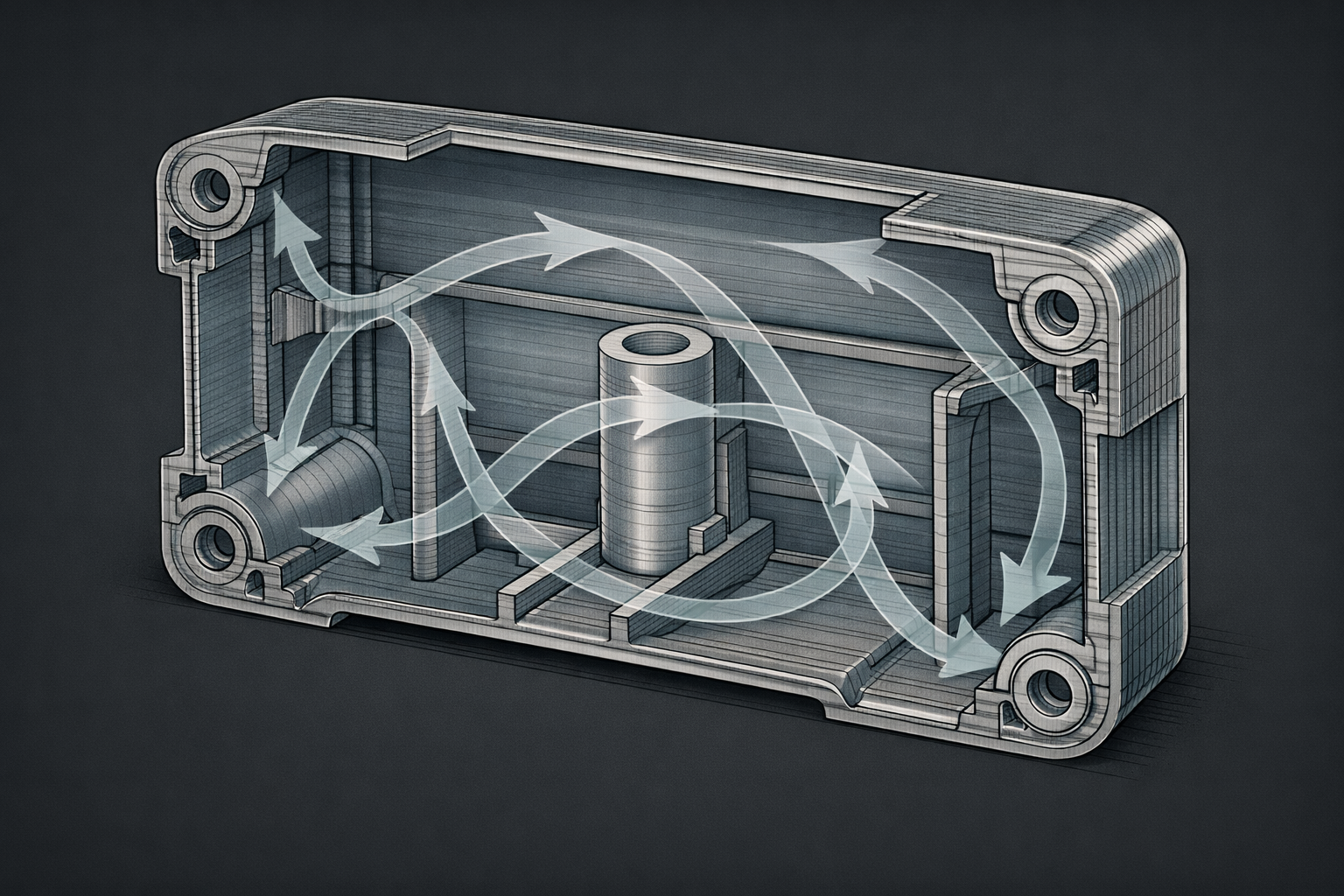

Complex Geometry, Curves, and Stress Paths

Our products rarely rely on simple rectangular forms. Curves are structural, not decorative. They distribute stress, guide user interaction, and integrate electronics naturally.

Rapid prototyping allows us to:

- Observe how stress flows through curved shells

- Identify thin regions prone to cracking

- Adjust internal ribbing without altering external form

- Ensure curved enclosures don’t introduce unintended assembly stress

FDM exposes weaknesses in load paths. SLA reveals where precision is critical. Together, they let us shape enclosures that are both elegant and durable.

Accelerating User Feedback Without Locking Design

One of the most valuable outcomes of rapid prototyping is early user exposure—not for validation, but for discovery.

By using FDM for early field units and SLA for refined evaluation models, we gather feedback on:

- How products are handled

- Where wear naturally occurs

- Which surfaces users touch most

- How intuitive assembly and servicing feels

Crucially, this happens while designs are still fluid. No tooling constraints. No sunk-cost pressure. Just informed iteration.

Prototyping as a Cultural Discipline

The real advantage isn’t the printers—it’s the mindset.

Rapid prototyping at Hoomanely is:

- Intentional, not reactive

- Structured, not ad-hoc

- Integrated with mechanical, electrical, and industrial design

Every prototype answers a question. Every iteration closes uncertainty. SLA and FDM are tools, but the discipline is in knowing when and why to use them.

Conclusion: Speed with Direction

Rapid prototyping is often framed as speed versus quality. In reality, when practised deliberately, it’s speed through quality.

By leveraging FDM for mechanical confidence and SLA for precision and visual truth, we ensure that our products mature quickly without accumulating hidden debt. Complex geometries become predictable. Curved enclosures become reliable. Early user feedback becomes actionable.

This is how Hoomanely moves fast—without breaking trust, structure, or intent.

Rapid prototyping isn’t about printing parts.

It’s about printing certainty.