The Art of Resilient Design: Building Production-Grade BOMs with Second-Source Strategy

Introduction: When Supply Chains Falter, Design Excellence Prevails

The global semiconductor shortage of 2021-2023 taught the industry a hard lesson: design decisions made in the schematic capture phase have far-reaching consequences that ripple through manufacturing, supply chain management, and ultimately, your ability to deliver products to customers.

At Hoomanely, we've witnessed firsthand how a single-source component can become a production bottleneck. A processor that ships in 16-week lead times. A specialized sensor with allocation restrictions. A power management IC unavailable from any distributor. In each case, companies with rigid BOMs faced impossible choices: delay product launches, redesign at enormous cost, or accept inflated component pricing on gray-market suppliers.

We chose a different path. Rather than treating component selection as a one-time decision, we've embedded second-source strategy and comprehensive lifecycle tracking into our design methodology from day one. Today, I want to share how our modular vBus architecture—combined with rigorous BOM engineering—creates products that are not just functionally excellent, but resilient to supply chain disruption.

The vBus Advantage: Modularity Meets Supply Chain Resilience

Before diving into specific BOM strategies, it's worth highlighting how our vBus modular architecture creates unprecedented opportunity for component flexibility.

In traditional monolithic system design, a core processor choice locks you into a specific peripheral ecosystem. Change your main processor, and you've potentially changed your power management, your communication interfaces, your debug infrastructure. Redesign becomes catastrophic—affecting schematic, PCB layout, firmware, everything.

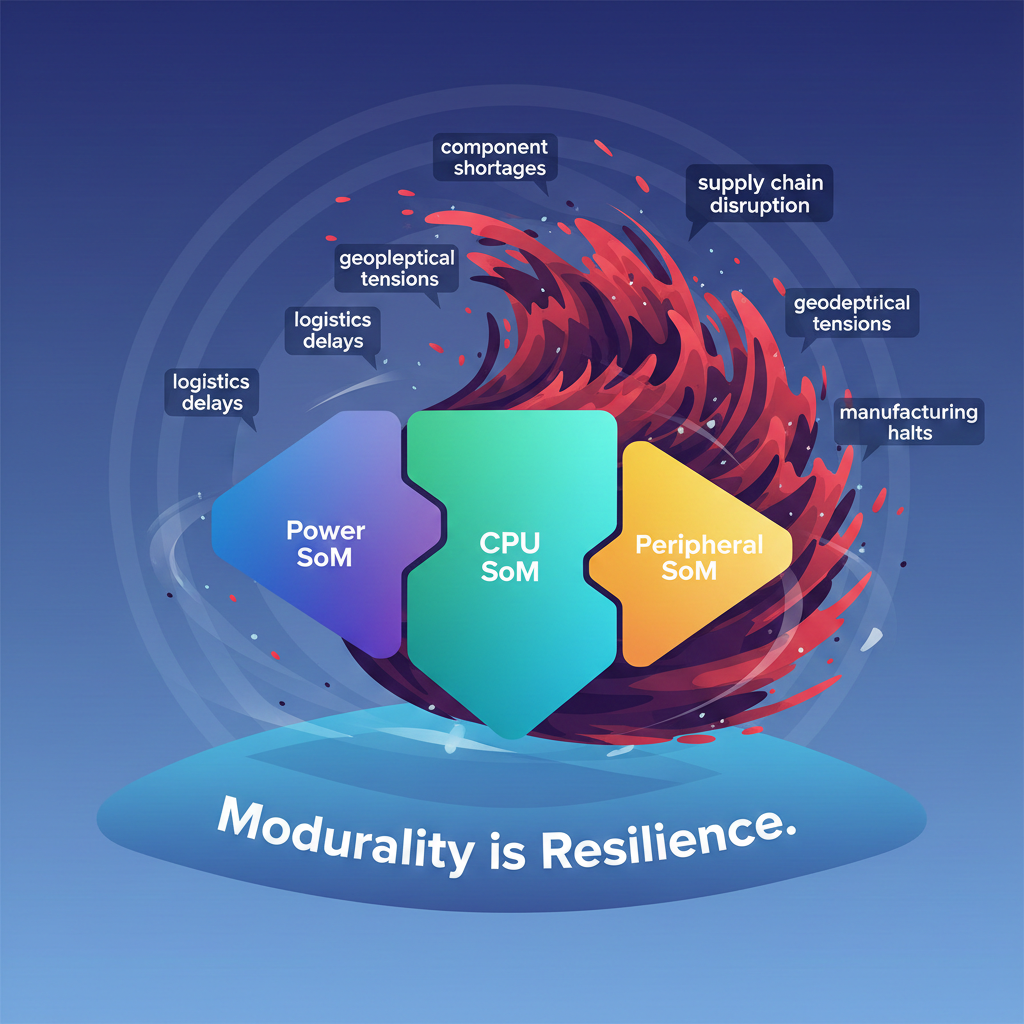

vBus inverts this relationship. Our modular SoM architecture means component choices are scoped within individual modules. A CPU SoM houses the processor and core components. A Power SoM contains power management and regulation. Peripheral SoMs handle specific sensors or interfaces. The brilliance: you can redesign power management or swap processors without affecting sensor modules.

This isolation enables aggressive second-source strategy. If your preferred CPU becomes unavailable, you can redesign just the CPU SoM—keeping the rest of the product unchanged. Or better yet, maintain multiple CPU SoM designs simultaneously, allowing different customer configurations or market segments to use whatever processor is currently available.

This is where vBus and supply chain resilience converge. Modularity isn't just about functional flexibility; it's about supply chain optionality.

Strategic Component Selection: The Foundation

Identifying Critical Components

Not all components deserve equal BOM attention. A 0.1µF ceramic capacitor has thousands of interchangeable sources. A s MEMS gyroscope sensor has maybe three qualified manufacturers globally.

Our selection process begins with component criticality analysis:

Tier 1 - Critical Components: Processors, microcontrollers, specialized sensors, wireless modules, power management ICs—components where no direct equivalents exist or where equivalents would require significant redesign. Every Tier 1 component receives dedicated second-source analysis.

Tier 2 - Important Components: Analog front-end ICs, memory (DRAM, flash), communication transceivers (Ethernet, CAN)—components where alternatives exist but might require firmware or hardware tweaks. Tier 2 components receive secondary source identification when feasible.

Tier 3 - Standard Components: Resistors, capacitors, inductors, discrete transistors, standard logic ICs—commoditized components with hundreds of interchangeable sources. Tier 3 components are grouped by specification (value, tolerance, package) rather than specific part numbers.

This tiered approach focuses engineering effort where it matters most. We don't waste resources finding second sources for a 10µF capacitor (distributors can substitute equivalent parts automatically), but we obsess over finding CPU alternatives.

The Second-Source Mandate

Here's our design methodology: No Tier 1 component enters a design without at least one qualified second source identified and validated.

This isn't just theoretical. During design review, the component selection team presents:

- Primary component choice (preferred for cost, performance, lead time)

- At least one second-source alternative (equivalent or near-equivalent functionality)

- Pin-compatibility analysis (can they be drop-in replacements, or would PCB re-spin be needed?)

- Performance comparison (specifications, thermal characteristics, footprint differences)

- Cost comparison (primary vs. secondary, including volume discounts)

- Availability assessment (typical lead times, supply chain stability)

Only when all this documentation is complete does the design proceed to schematic. This upfront investment saves enormous pain downstream.

Drop-In vs. Redesign Components

Here's a critical distinction we've learned: not all second sources are created equal.

Drop-in Compatible: The alternative component uses the same pinout, package, and electrical interface. You can swap it into the PCB without layout changes. Firmware might need minor tweaks, but hardware remains identical. These are gold—they provide maximum flexibility.

Pin-Compatible but Different: Same pinout but different power requirements, voltage levels, or peripheral interfaces. PCB remains unchanged, but firmware requires adaptation. Still valuable, but with higher risk if integration isn't properly planned.

Different Pinout: The alternative component requires PCB re-layout. This is expensive and time-consuming, but sometimes it's the only option. When this is the case, we design the PCB routing specifically to accommodate both options—using test pads or optional trace paths that allow swapping between versions.

Different Package: The alternative uses a different size or mounting style (BGA vs. QFP, for example). This typically requires PCB redesign and is avoided whenever possible—it's a last resort option.

Our design team's preference hierarchy: drop-in compatible > pin-compatible > different package > different pinout. We actively redesign around component choices to maintain maximum flexibility.

The Production-Grade BOM: Detailed Structure

Now, let's talk about what a truly production-ready BOM looks like at Hoomanely. This is far more sophisticated than a simple part list.

Core BOM Columns

Our standard BOM spreadsheet includes:

Reference Designator (RefDes): U1, R47, C22—unique identifier for each component placement. Used for assembly, testing, and traceability.

Component Description: Concise technical specification. "ARM Cortex-M4 MCU, 1MB Flash, 256KB SRAM, 100 LQFP" provides much more information than just "STM32L4+".

Quantity: How many of this component per board. Critical for cost analysis and supply planning.

Primary Part Number: The preferred manufacturer part number with full specifications. Example: STM32L476RGT6—specific enough that there's no ambiguity.

Primary Manufacturer: Who makes it. "STMicroelectronics" not just "ST".

Primary Distributor(s): Where it's typically sourced. Digi-Key, Mouser, Arrow, etc. Including multiple distributors here is key—if one is out of stock, you have backup options.

Second-Source Strategy Columns

This is where most BOMs fall short, and where production-grade BOMs shine:

Secondary Part Number 1: The primary alternative. Fully qualified and documented.

Secondary Manufacturer 1: Who produces the alternative. Different manufacturer = better supply chain resilience than two sources from the same company.

Secondary Distributor(s): Where the alternative typically sources. Ideally different distribution channels than primary.

Secondary Part Number 2 (Optional): For extremely critical components (like processors), we sometimes identify a tertiary option.

Pin Compatibility: Clear statement: "Drop-in" or "PCB re-spin required" or "Firmware modification needed".

Performance Comparison: Concise summary of differences. "Slightly higher power consumption (+5%) but better thermal characteristics" or "Identical specs, different package (BGA).

Second-Source Validation Status: "Qualified," "Under Evaluation," "Prototyped," or "Field-Tested." Never include unqualified alternatives—they must have been actually tested, not just theoretically equivalent.

Lifecycle and Availability Columns

This section answers the crucial question: Will this component be available when I need it?

Manufacturer Lifecycle Status: Is this component in active production, mature/stable, or approaching end-of-life? This determines your supply-chain urgency.

Typical Lead Time (Primary): Current average lead time in weeks. "16 weeks" vs. "4 weeks" completely changes your purchasing strategy.

Typical Lead Time (Secondary): Comparison to second source. If both are 16+ weeks, you have a problem and need to redesign.

Expected Lifecycle (Years): When does the manufacturer plan to discontinue this component? A processor with 5+ years of planned production is safe. One with 2 years means you need an aggressive second-source plan.

Last-Buy Window: If the manufacturer has announced end-of-life, this column specifies the last date to purchase components at list price before being forced to buy from remaining inventory (at premium prices).

Recommended Inventory Level: How many units to stock as safety buffer? For critical long-lead components, we sometimes recommend 3-6 month buffer inventory.

Cost and Commercial Columns

Unit Cost (Primary): Cost per component at your current/planned volume. Example: "$2.47 @ 10K units". Absolutely critical that volume assumptions are documented—$2.47 at 10K units is very different from $2.47 at 100K units.

Extended Cost (Primary): Unit cost × quantity per board. If you need 3 of this component per board, extended cost = unit cost × 3.

Unit Cost (Secondary): Comparison pricing for the alternative.

Extended Cost (Secondary): Total cost of secondary component per board.

Cost Delta: The price difference between primary and secondary. "$0.12 more per board" guides decisions about when to switch to second source.

Volume Discount Tiers: Often sourced components have volume-based pricing. Document the break points: 1-100 units at price X, 100-1000 at price Y, 1000+ at price Z. This is crucial for go/no-go decisions on manufacturing volumes.

Lead-time Cost Premium: What does expedited shipping cost if you need the component faster? Often there's a percentage premium for faster lead times—documentation enables informed risk-taking during supply disruptions.

Traceability and Quality Columns

Manufacturer Part Lifecycle Code: Some manufacturers use specific codes for active, mature, or discontinued status. Document these explicitly.

RoHS/Environmental Compliance: Is this component RoHS-compliant? Lead-free? Important for geographic certifications and long-term viability.

Quality/Reliability Grade: Is this industrial-grade, automotive-grade, mil-spec? Has direct bearing on product applications and certifications.

Qualified by: Which engineer validated this component? Adds accountability and enables quick follow-up if questions arise.

Date Qualified: When was the component last formally qualified? Helps identify when re-qualification might be needed.

Test Method: How was it qualified? "Prototyped on CPU SoM," "Integrated into test harness," "Field-tested in production units"—different validation levels indicate different confidence levels.

Known Issues/Errata: Any quirks discovered during design or testing? "Requires 100ms settle time after power-up" or "SPI timing marginal at 48MHz" ensures future engineers know the gotchas.

Design-Phase Component Validation

Prototype and Validation Flow

Second-sourcing isn't just paperwork—it requires hands-on validation. Our process:

1. Initial Evaluation: Schematic and datasheet review of primary and secondary options. Can they work, theoretically?

2. Prototype Build: Both primary and secondary components soldered onto the same PCB (using optional pads if necessary). Side-by-side validation on actual hardware.

3. Functional Testing: Both versions run the same test suite. Does the secondary option meet all performance requirements?

4. Stress Testing: Temperature cycling, voltage variations, radiation if applicable. Ensuring secondary option behaves identically under stress.

5. Long-Term Validation: Some components (especially power management or reliability-critical components) get weeks of continuous operation testing before mark as "fully qualified."

6. Documentation: All results, measurements, and observations recorded. Later, if you need to switch to secondary source mid-production, you have complete validation data.

This process typically adds 2-4 weeks to the design cycle but saves months if supply disruption occurs.

Cross-Team Review

Component selection involves more than just electrical engineers:

Electrical Team: Does it meet electrical requirements?

Firmware Team: Can firmware support both variants? Are there differences in peripheral interfaces, register maps, or behavior that require code changes?

Manufacturing Team: Can assembly equipment handle both options? Some alternatives might use different packages requiring solder profile changes.

Supply Chain Team: Real-world availability data. A great component on paper might have chronic supply issues. The team knows.

Quality Assurance: Failure history. If the secondary component has higher field failure rates, that data surfaces here.

This collaborative approach catches issues that pure electrical design would miss.

Lifecycle Tracking: Building the Living BOM

A production-grade BOM isn't static—it's a living document that evolves with component lifecycles and market conditions.

Continuous Monitoring

We've implemented automated systems that track component lifecycle status:

Lifecycle Alerts: When a component enters "nearing end-of-life" status, alerts trigger to component engineering and supply chain teams. Decision point: redesign for alternative now, or stock up on inventory?

Lead-Time Tracking: We monitor typical lead times for each component. When lead time spikes unexpectedly, systems flag it. Early warning enables proactive sourcing decisions.

Price Trending: Component pricing fluctuates based on market conditions. We track these trends to identify buy-in opportunities or to trigger redesign decisions if alternatives become significantly cheaper.

Availability Allocation: When components enter allocation (limited availability distributed by distributors), we know immediately and can adjust production planning or trigger alternative sourcing.

The Rolling Forecast

Beyond today's BOM, we maintain forward-looking component availability forecasts:

- 3-month forecast: What components might become constrained?

- 6-month forecast: What lifecycle changes should we anticipate?

- 12-month forecast: What architectural changes should we plan for?

This forward-looking approach enables design changes before they become emergencies. If we see that a key processor is heading toward end-of-life in 18 months, we have time to design and qualify a successor module rather than panicking when supply finally runs out.

vBus and BOM Modularity: Strategic Advantage

Here's where vBus truly shines in the BOM context. Each SoM has its own detailed BOM with dedicated second-source strategy. The modular architecture means:

Isolated Impact: A CPU processor change affects only the CPU SoM's BOM, not Peripheral or Communication SoMs.

Reusable Modules: A Power SoM design might appear in multiple product lines. Optimize its BOM once, benefit across all products.

Variant Management: You can offer multiple CPU SoM variants (low-cost variant, high-performance variant, automotive-grade variant) each with its own optimized BOM, all working with identical Peripheral and Communication SoMs.

Supply Chain Optimization: If a specific processor becomes constrained, you have other CPU SoM designs ready to substitute. Customers might get a "CPU SoM variant B" instead of variant A, but the overall system works identically. No product delay, no customer disruption.

This architectural flexibility transforms second-source strategy from "hope for the best" to "strategic optionality."

The Extended BOM: Beyond Component Lists

Modern production-grade BOMs extend beyond parts:

Firmware Compatibility Matrix: Which firmware versions work with which component variants? Critical for manufacturing and field support.

Mechanical Compatibility: Are there mechanical clearance differences between component alternatives? Height, clearance, thermal dissipation considerations.

Test Coverage: Which test cases validate each component? Ensures manufacturing and QA know what must be tested.

Assembly Notes: Any special handling? "Requires X-ray inspection after reflow" or "Requires cleaning after wave solder" goes here.

Supply Chain Risk Assessment: For each critical component, documented risk profile: "High availability risk—maintain 6-month inventory buffer" vs. "Mature, stable component—standard lead time sourcing acceptable."

Regulatory/Certification Impact: How does component choice affect regulatory approvals? Does choosing automotive-grade component enable additional market certifications?

Environmental/Sustainability: Lead-free, RoHS compliance, conflict minerals reporting—increasingly important for corporate responsibility and market access.

Execution: From BOM to Manufacturing

MES Integration

The BOM doesn't live in a spreadsheet gathering dust. It's integrated into your Manufacturing Execution System where it drives:

- Bill of Materials Management: Manufacturing pull exactly the quantities and part numbers specified

- Supply Chain Planning: Procurement knows exactly what's needed and when

- Test Coverage: Automated test systems load component-specific test profiles

- Traceability: Each manufactured unit gets linked to exact BOM revision and component lot numbers

- Quality Analytics: Field failures correlate back to component choices and supplier

This integration transforms the BOM from documentation into operational intelligence.

Revision Control and Change Management

As products evolve, components change. Rigorous version control is essential:

- BOM Revision History: Every change tracked with date, author, reason, and impact assessment

- Engineering Change Orders (ECOs): Formal process for component substitutions with approval chain

- Compatibility Analysis: If a component changes, what firmware revisions still work? What manufacturing batches are affected?

- Field Service Impact: If a failure occurs, technicians know exactly which component variant was installed in which production batch

Conclusion: Resilience Through Foresight

The production-grade BOM—with rigorous second-source strategy and comprehensive lifecycle tracking—is perhaps the most underappreciated tool in modern electronics manufacturing. It's unsexy compared to processor performance or wireless range. Yet it determines whether your company thrives or merely survives when supply chain disruptions inevitably occur.

At Hoomanely, supply chain resilience isn’t a fortunate outcome—it’s an engineered capability. We’ve intentionally embedded second-source strategy, lifecycle foresight, and rigorous qualification processes directly into our design workflow. By identifying alternatives early, validating them thoroughly, and maintaining real-time visibility into component lifecycles, we’ve ensured uninterrupted production. And by building modular architectures like vBus, we’ve enabled seamless component flexibility that keeps our manufacturing timeline predictable and fast, even under global supply constraints.

In an era of supply chain volatility, this kind of engineering foresight separates industry leaders from the rest of the pack. It's how you build products that customers can rely on—no matter what the world throws at you.