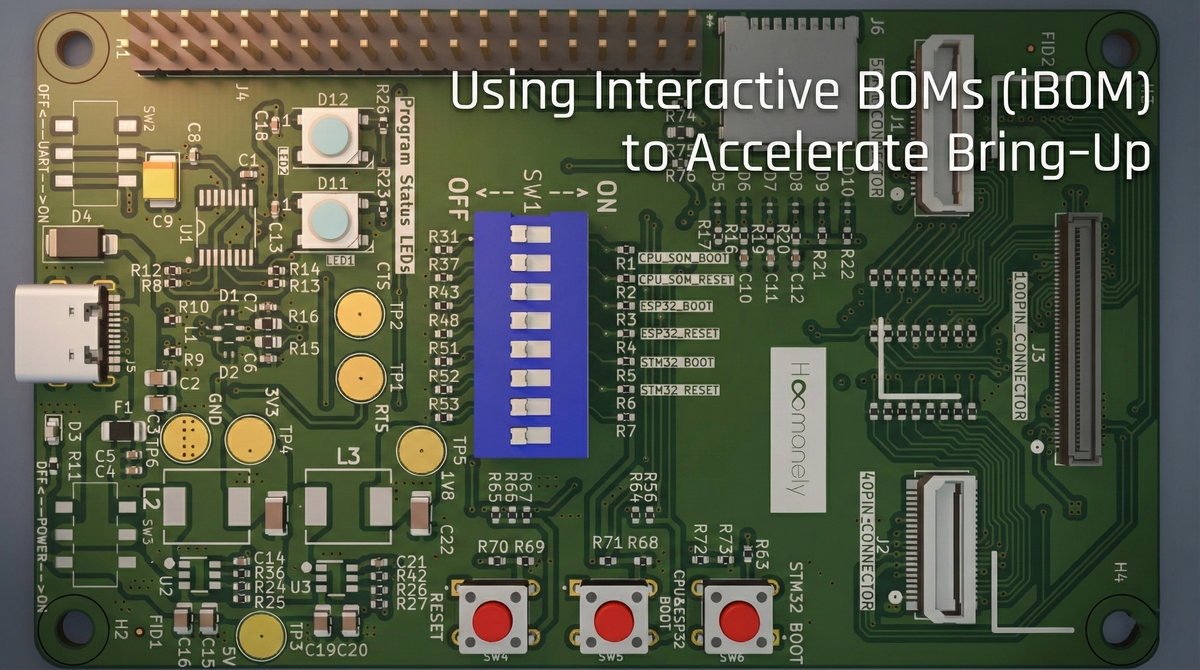

Using Interactive BOMs (iBOM) to Accelerate Bring-Up

Introduction: Where Design Intent Meets the Bench

The moment a PCB arrives on the bench, the nature of engineering changes. Abstract decisions made in schematics and layouts must now withstand probing, measurement, assembly variation, and time pressure. Bring-up is where design intent is either immediately legible — or painfully opaque.

At Hoomanely, as our vBus-based products grew in complexity and modularity, we realised that traditional documentation workflows were becoming a bottleneck. Static PDFs, printed assembly drawings, and spreadsheet BOMs could not keep pace with the speed at which our teams needed to reason about hardware during bring-up. The solution wasn’t more documents—it was better interfaces.

Interactive BOMs (iBOMs) became a foundational part of our bring-up workflow. Not as an afterthought or convenience feature, but as a deliberate design artefact that bridges layout, assembly, and live debugging. When done right, an iBOM turns a populated PCB into a navigable system—one where engineers, technicians, and manufacturing partners all speak the same visual language.

This article explores how iBOMs fit into our hardware workflow, how they accelerate bring-up across vBus modules, and the considerations that matter when you treat them as first-class engineering tools.

The Bring-Up Challenge in Modular Hardware

Density, Variants, and Human Bandwidth

vBus products are intentionally modular. CPU SoMs, Power SoMs, Peripheral SoMs, and carrier boards are combined and recombined across multiple SKUs. While this architecture accelerates product development, it introduces bring-up challenges:

- The same component reference may exist across multiple board variants

- Power domains overlap across modules

- High-density layouts limit visual inspection

- Early bring-up often involves partial populations and experimental assemblies

In such environments, the limiting factor during bring-up is rarely signal access—it’s context. Engineers need to answer questions quickly:

- What exactly is populated on this board revision?

- Where is that component physically located—top or bottom, near which nets?

- Which passives are tied to this power rail or signal path?

Static BOMs and PDFs force engineers to context-switch between tools. iBOMs collapse that distance.

iBOM as a Workflow Primitive

A Live Map of the Board

An iBOM is more than a clickable BOM. In practice, it becomes a spatial index of the hardware:

- Component list linked bidirectionally to PCB layout

- Immediate highlighting of reference designators

- Layer awareness (top/bottom visibility)

- Real-time filtering by value, footprint, net relevance, or population state

During bring-up, this turns the board into a searchable system. Engineers no longer ask “Where is R47?”—they select it and let the system answer visually.

This shift sounds subtle, but its impact is profound. It reduces cognitive load at the exact moment engineers need clarity most.

Integrating iBOMs into the Bring-Up Flow

Before the Board Arrives

Well before the first boards are assembled, iBOMs already influence outcomes:

- Assembly intent is validated visually

- Optional/DNP components are clearly tagged

- Footprint-to-value mismatches are easier to catch

- Orientation assumptions are visible without interpretation

By the time boards arrive, the iBOM already reflects a shared understanding between design and assembly.

During Initial Power-On

Bring-up typically starts with power integrity checks. iBOMs accelerate this phase by allowing engineers to:

- Filter all components tied to a specific rail

- Instantly locate decoupling networks around regulators or processors

- Cross-reference reference designators with probe access points

Instead of tracing nets mentally across layers, the engineer navigates visually. This is especially valuable on compact vBus modules where multiple regulators and domains coexist in tight proximity.

Debugging and Signal Validation

As firmware teams begin interacting with hardware, iBOMs serve as a common reference:

- Hardware engineers can point firmware engineers to exact component clusters

- Probe points can be identified without ambiguity

- Population-specific behaviour (variant A vs variant B) is immediately obvious

This shared visibility reduces back-and-forth and keeps conversations grounded in the physical reality of the board.

Scaling Bring-Up Across Variants

One Layout, Many Assemblies

A recurring strength of iBOMs is how naturally they support variant-aware bring-up.

In the vBus ecosystem, a single PCB layout may support:

- Development builds

- Production builds

- Region-specific configurations

- Experimental or feature-gated variants

By encoding population state directly into the iBOM, the same visual artefact adapts across contexts. Engineers no longer rely on tribal knowledge or memory—what’s populated is what’s shown.

This becomes especially important when multiple teams are bringing up different variants in parallel.

Collaboration Beyond the Engineering Team

Assembly and Manufacturing Alignment

iBOMs are not just engineering tools—they are alignment tools.

Manufacturing partners benefit from:

- Clear visualization of component placement

- Rapid identification of missing or misoriented parts

- Reduced ambiguity around optional components

Because the iBOM is derived directly from layout data, it reflects engineering intent more faithfully than hand-maintained documents. This consistency improves first-pass outcomes and reduces clarification loops during early builds.

Field and Service Support

As products mature, iBOMs continue to provide value:

- Field engineers can locate components quickly during diagnostics

- Service teams can identify replaceable elements without dismantling assemblies

- Documentation remains accurate even as revisions evolve

The same artefact that accelerates bring-up also improves long-term maintainability.

Designing iBOMs That Actually Help

Treating iBOMs as Interfaces

The effectiveness of an iBOM depends on how intentionally it is designed. Some considerations that matter in practice:

- Consistent reference designators across modules and revisions

- Clear separation of functional clusters in layout

- Meaningful value naming (beyond just “10k” or “0.1uF”)

- Thoughtful use of comments and metadata

An iBOM inherits the strengths—and weaknesses—of the underlying layout discipline. When the layout is readable, the iBOM becomes powerful. When the layout is chaotic, interactivity cannot compensate.

Workflow Considerations (and Why They Matter)

Rather than thinking in terms of “pitfalls,” we’ve learned to treat certain patterns as design constraints for iBOM-driven workflows:

- Overloading the BOM with non-essential metadata reduces clarity

- Inconsistent naming across libraries erodes trust

- Treating iBOM generation as a post-layout export misses its full value

The key insight is simple: iBOMs work best when they are expected to be used, not merely generated. When engineers know that bring-up will rely on them, design decisions naturally adapt.

Why This Changes the Pace of Development

From Interpretation to Navigation

Traditional bring-up often feels like translation—turning schematics and layouts into mental models under time pressure. iBOMs replace translation with navigation.

Engineers spend less time interpreting documents and more time reasoning about behaviour. The result is not just faster bring-up, but calmer bring-up—where confidence replaces guesswork.

In modular systems like vBus, that confidence compounds across teams, products, and generations.

Conclusion: Documentation That Works at Human Speed

Interactive BOMs succeed not because they are sophisticated, but because they respect how engineers actually work. They acknowledge that bring-up happens on benches, under time constraints, across teams with different expertise levels.

By integrating iBOMs deeply into our hardware workflow, Hoomanely has turned bring-up from a document-heavy process into an interactive, visual experience. One where design intent remains visible long after the PCB leaves the CAD tool.

This is not about replacing engineering judgment—it’s about supporting it. When the board can explain itself, engineers are free to focus on what matters most: understanding behaviour, validating assumptions, and moving products forward with confidence.

In fast-moving hardware ecosystems, clarity is a competitive advantage. iBOMs are one of the quiet tools that make that clarity possible—board by board, module by module, from first power-on onward.