Building Reliable USB-Powered IoT Devices: A Repeatable Method

At Hoomanely, USB isn’t just a connector—it’s a critical part of the power architecture.

Almost every product we build uses USB for one or more purposes:

- Powering the device

- Configuring firmware

- Transferring logs or data

But USB is more than a port. It defines an electrical relationship between two devices—

who supplies power, who consumes it, and how much current is allowed.

With USB-C and USB Power Delivery (USB-PD), voltages can increase and current levels can scale dynamically. That means USB isn't just “plug and play”—it's negotiate, monitor, and protect.

Across our products—from 5V @ 500mA sensor nodes to 15V @ 1A hubs/OTG devices—our approach remains the same:

USB becomes universal when designed with clear intent and engineering discipline.

Our approach focuses on:

- defining the USB role early (Host / Device / OTG),

- respecting USB power negotiation limits,

- building hardware protection around real-world failures.

The result?

USB just works—with any charger, any cable, any host.

USB Roles Decide the Electrical Design

Every USB port has a clearly defined role that dictates how power and data flow.

| Role | Function | Power Direction |

|---|---|---|

| USB Host | Initiates communication | Host → Peripheral |

| USB Device | Responds, never initiates | Host → Device |

| USB OTG | Can switch roles dynamically | Depends on role |

Our rule at Hoomanely

| Product Type | USB Role | Reason |

|---|---|---|

| IoT sensors / nodes (low power) | * USB Device | Only need power & config from PC |

| Gateways / hubs (medium power) | * USB Host/OTG | Manage other devices (USB sticks / peripherals) |

We lock this decision before PCB layout, because changing later means redesigning:

- schematic power paths,

- PD / role negotiation,

- load switches and limits.

Power Delivery & Current Limits

(Most USB failures come from ignoring this)

USB-PD can deliver up to 100W, but USB only gives you what you negotiate.

At Hoomanely, we design devices to operate safely under:

- USB device mode (≤ 500mA), and

- extended mode (≥ 1A) only when negotiation succeeds.

Our initialisation sequence:

- Start at <100mA (USB spec pre-enumeration limit)

- Enumerate and declare required current

- Only then draw 500mA / 1A / PD power

If PD or higher-current supply is available, we unlock higher-power features:

| Mode | Available Current | Device Behavior |

|---|---|---|

| 500mA (USB 2.0) | Always safe | Basic operation |

| 1A (USB Host / OTG / Fast charge) | When negotiated | Performance mode |

| USB-PD (if supported) | Up to 100W | High-load peripherals |

Never assume the port will behave. Negotiate or downgrade gracefully.

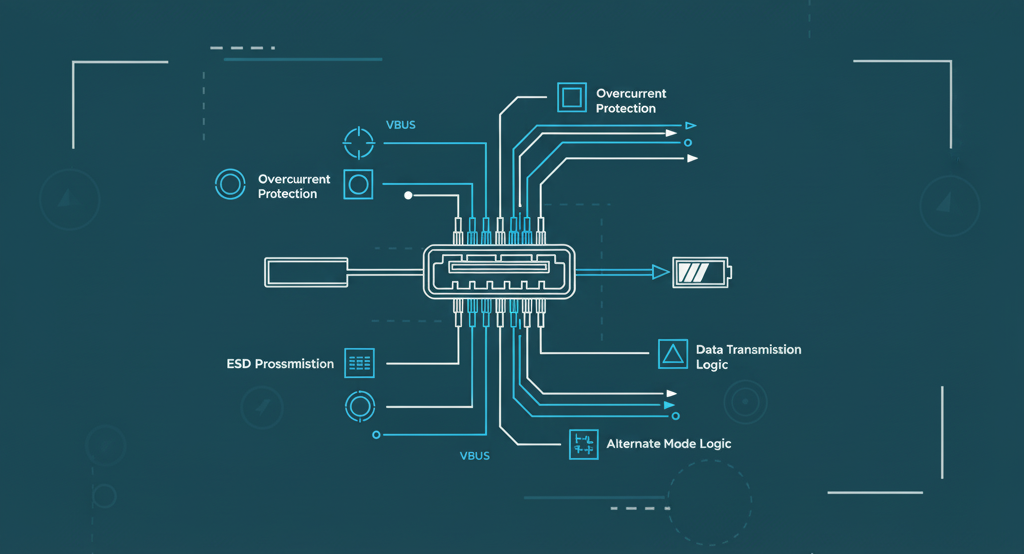

Safety & Protection:

(USB ports are exposed to real humans, not datasheets)

USB ports face:

- ESD from human touch,

- bad chargers (overvoltage),

- cable shorts (overcurrent),

- inrush spikes (capacitors charging on plug-in).

So our USB protection stack is always:

| Risk | What can happen | What we implement |

|---|---|---|

| Inrush Current | Port resets during plug-in | Soft-start + limited VBUS capacitance |

| Overcurrent | Melted traces / damaged connectors | Load switch w/ current limit (500mA or 1A) |

| Overvoltage | Cheap chargers output 9–12V | OVLO + Zener clamp + PD controller |

| ESD Events | Dead USB data lines | Low-cap TVS diodes ≤ 5mm from port |

Since adopting this stack, we’ve had zero USB field failures.

Clear Labelling Prevents Misuse

The number of hardware issues that are really user confusion is unbelievable.

So every USB port on our PCB is labeled with:

USB-C (Device)

5V 500mA Max

Silkscreen prevents 90% of user-induced failures.

Validation: If It Doesn’t Survive, It Doesn’t Ship

Before production, we stress-test USB against:

- Bad chargers

- Cheap cables

- Hot-plug cycles (1000+ insertions)

- ESD: ±8kV contact, ±15kV air

- Overvoltage (we intentionally feed 12V into USB input)

- Overcurrent (USB short-to-ground test)

If USB survives every bad scenario in the lab, it will survive the customer.

Final Takeaways

From multiple USB-PD powered product launches, these rules keep us safe:

- Decide the USB role early—host vs device defines everything.

- Respect power negotiation—never draw >100mA before enumeration.

- Protect the port—TVS, current limit, OVLO, soft-start are mandatory.

- Label the port—if a user can guess wrong, they will.

- Test for failure, not success—USB reliability is earned in validation.

USB becomes universal only when the engineer makes it predictable.